Fire resistant panel with structural inserts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

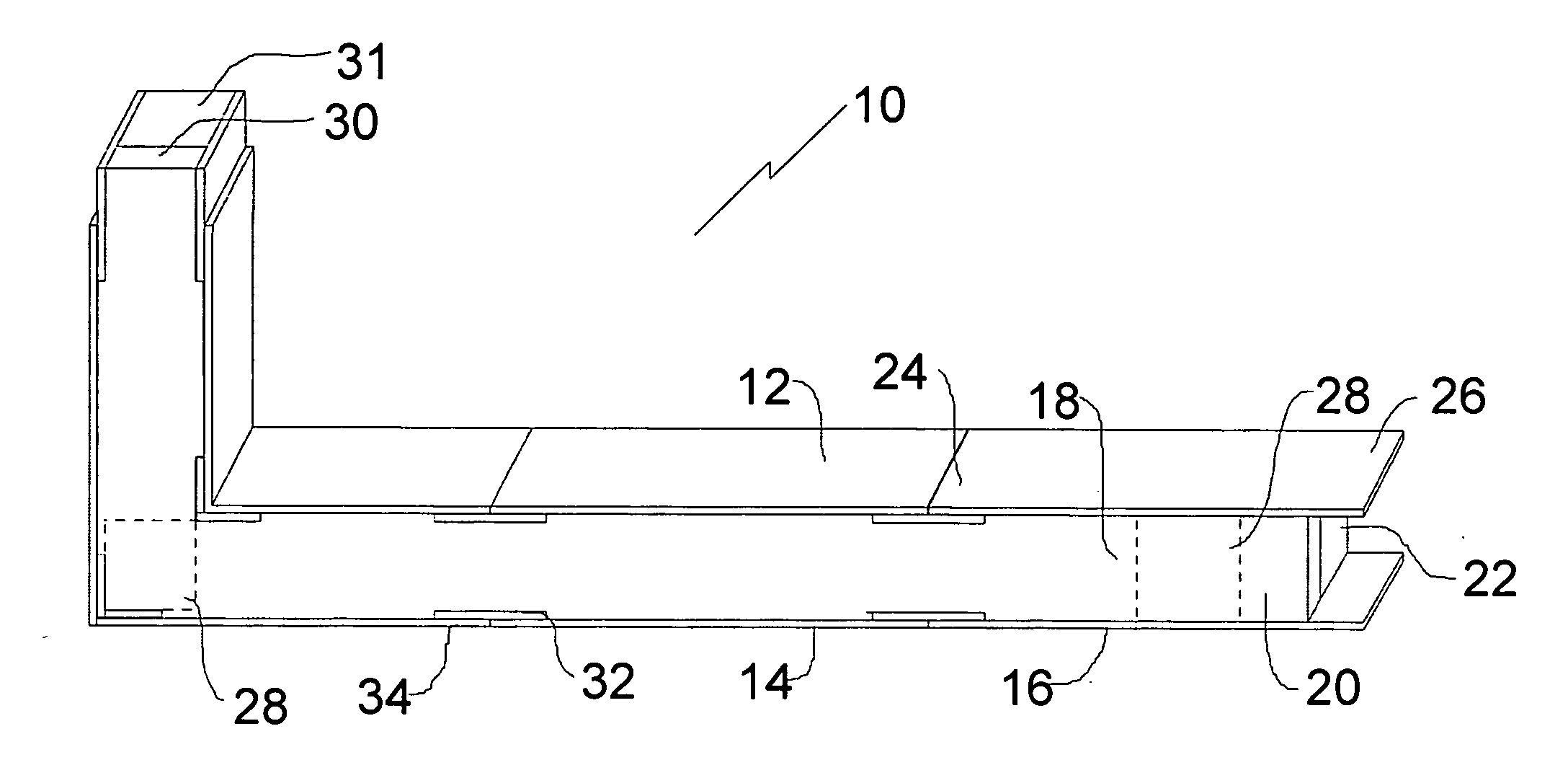

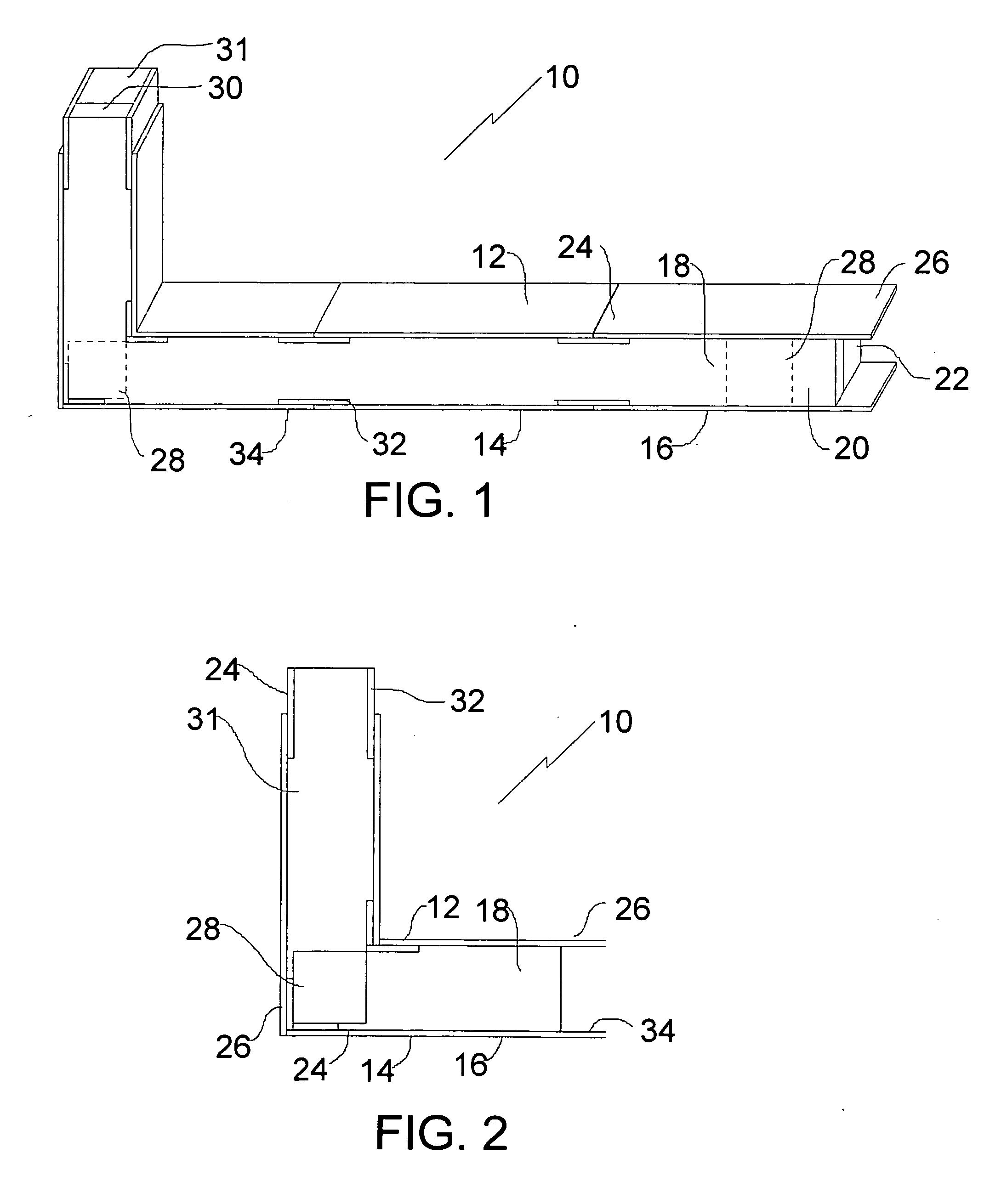

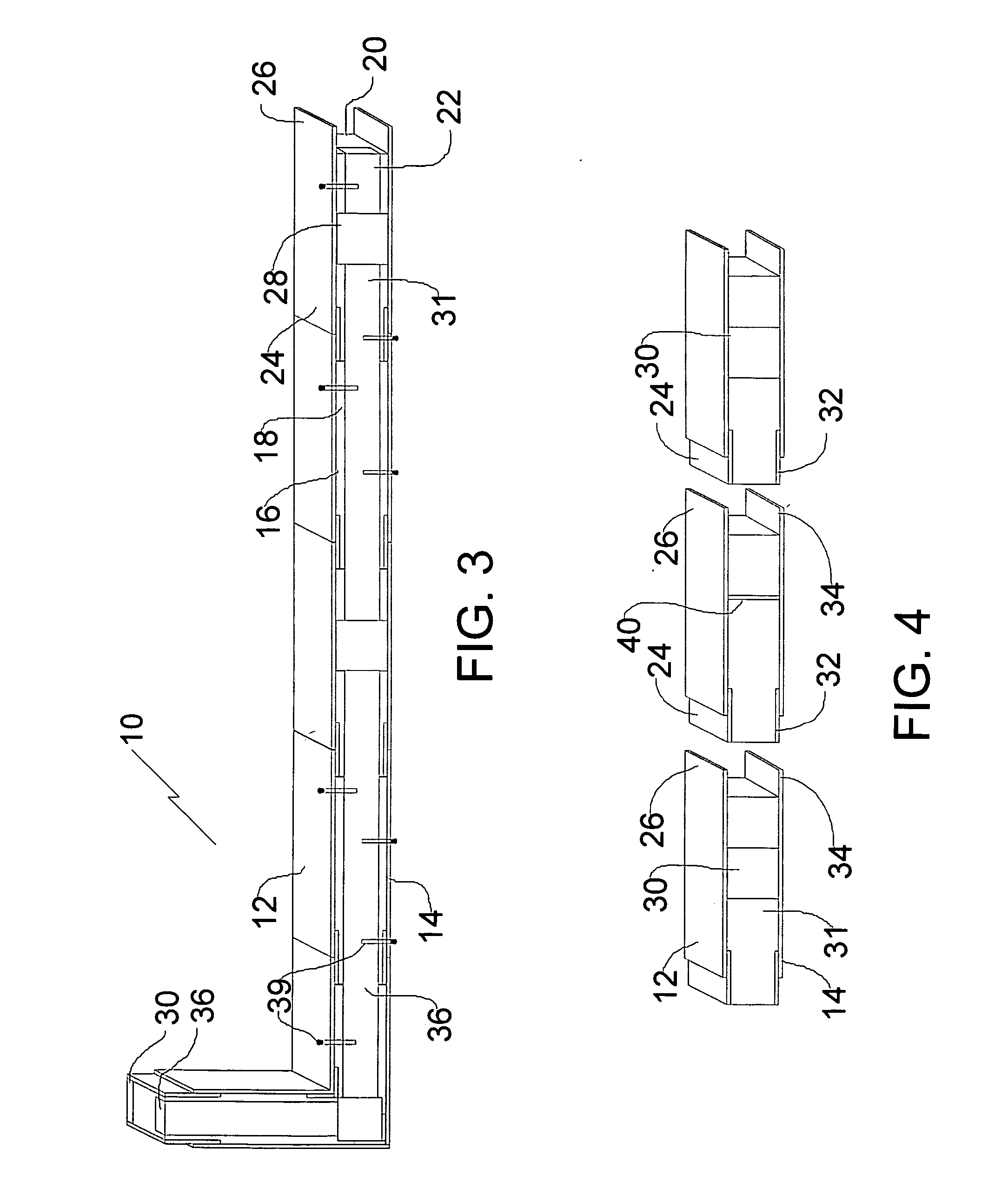

[0009] The preferred embodiment, a fire resistant panel generally identified by reference numeral 10, will now be described with reference to FIG. 1 through 4.

[0010] Structure and Relationship of Parts:

[0011] Referring now to FIG. 1, there is shown fire resistant panel 10, including a first sheet 12 and a second sheet 14. Sheets 12 and 14 are made from fire resistant material such as magnesium oxide, calcium silicate or cement, and are positioned in parallel spaced relation to define a sandwich structure 16 with a central cavity 18 that has a top 20, a bottom 22 and opposed ends 24 and 26. Referring to FIG. 3, cement posts 28 made from reinforced concrete are positioned in spaced relation in central cavity 18, with cement posts 28 being in a substantially vertical orientation between top 20 and bottom 22 of central cavity 18. Referring to FIG. 2, a cement beam 30 also made from reinforced concrete is positioned along top 20 of central cavity 18 and is supported by cement posts 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com