Encapsulated beam with anti-rotation system

a technology of anti-rotation and encapsulation beam, which is applied in the direction of carpet cleaners, cleaning machines, vehicles, etc., can solve the problems of inability to provide equal, little force, if any, and lack of uniform wiping force applied to the wiper blade, so as to increase the downward force of the wiper assembly and prevent any twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

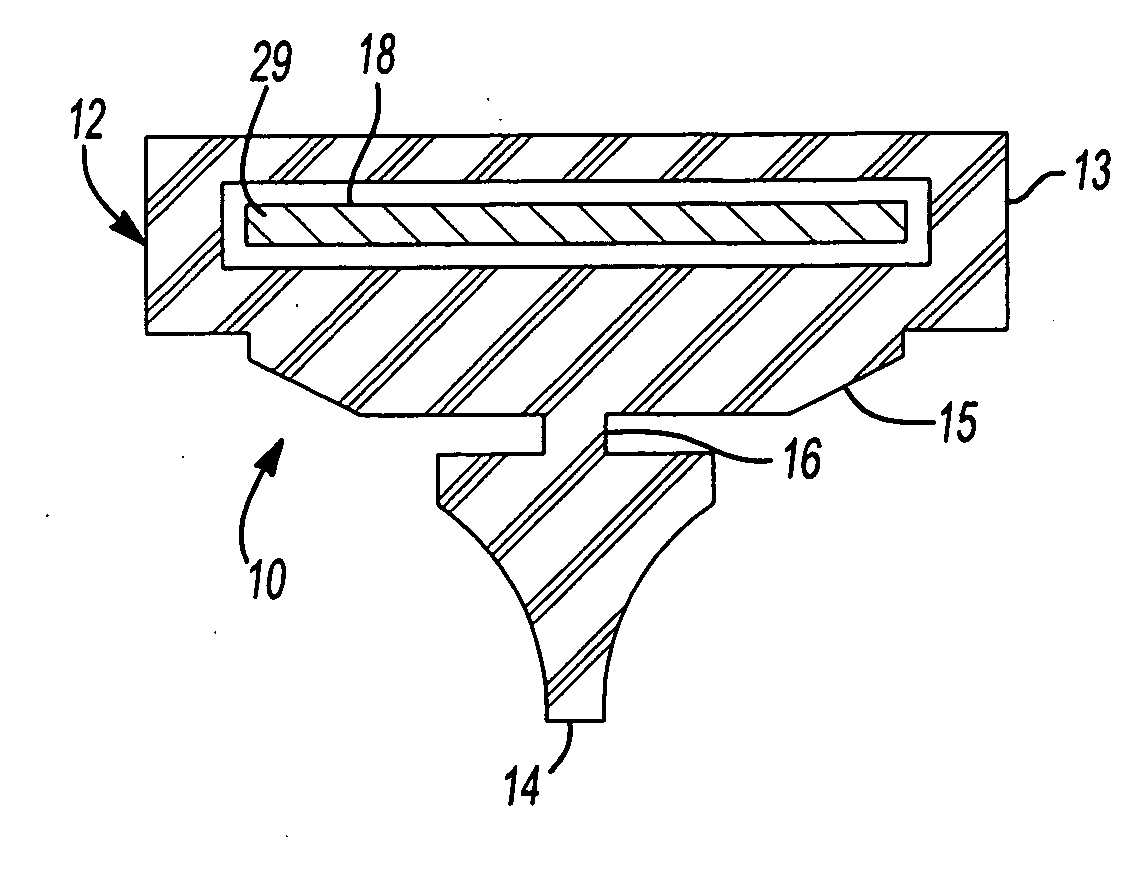

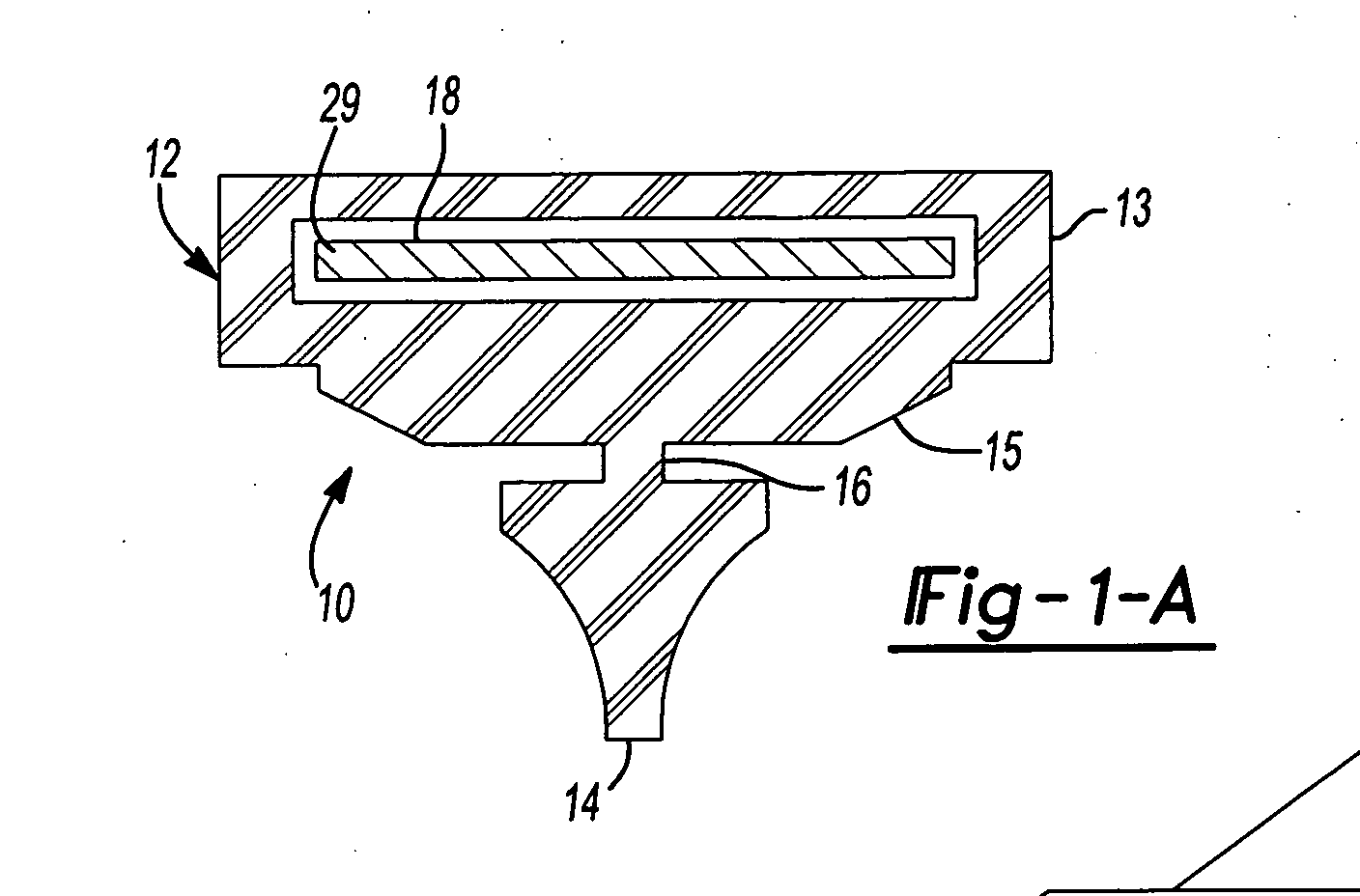

[0090] Referring now to the figures, particularly FIGS. A-1 and A-2, a first embodiment of the encapsulated beam assembly 10 of the present invention is shown comprising elongated resilient member 12 having a body 13 and a windscreen wiping edge 14 pivotally attached to a bottom side 15 thereof by a narrow flexible neck 16. The body 13 further comprises a longitudinal passage 18 through which an elongated beam 19 of a predetermined stiffness is inserted, thereby becoming encapsulated by the resilient member 12. The shape of the passage 18 is generally complementary to the shape of the elongated beam 19, thereby preventing the rotational twisting of the resilient member 12 independently of the elongated beam 19.

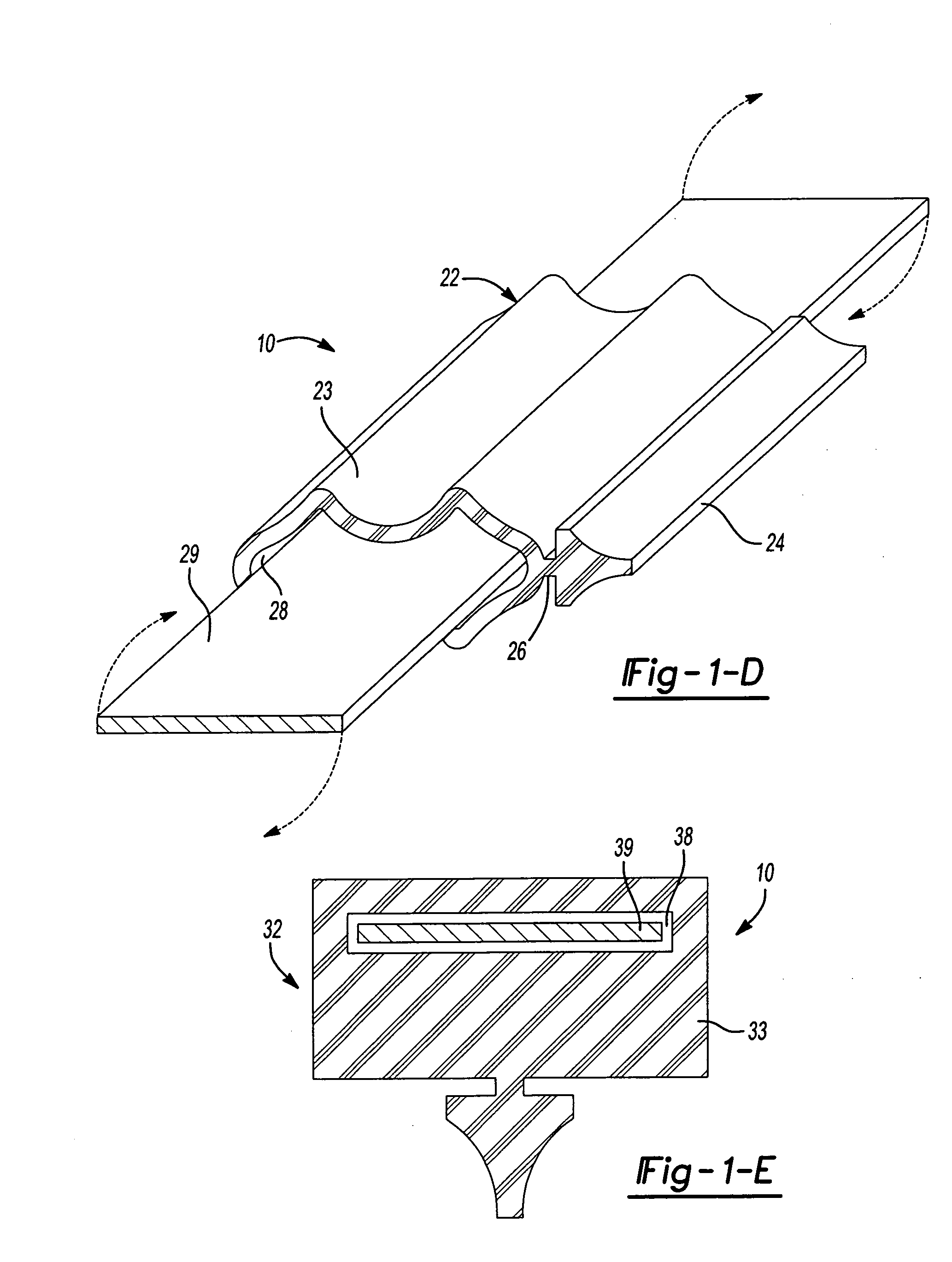

[0091] FIGS. A-3 and A-4 illustrate an alternative embodiment of the encapsulated beam assembly 10 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com