Vacuum eliminator

a vacuum eliminator and vacuum technology, applied in water installations, thin material processing, construction, etc., can solve the problems of not being able to achieve the effect of balancing the safety of returning water operation, avoiding denaturation and failure, and avoiding prior ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

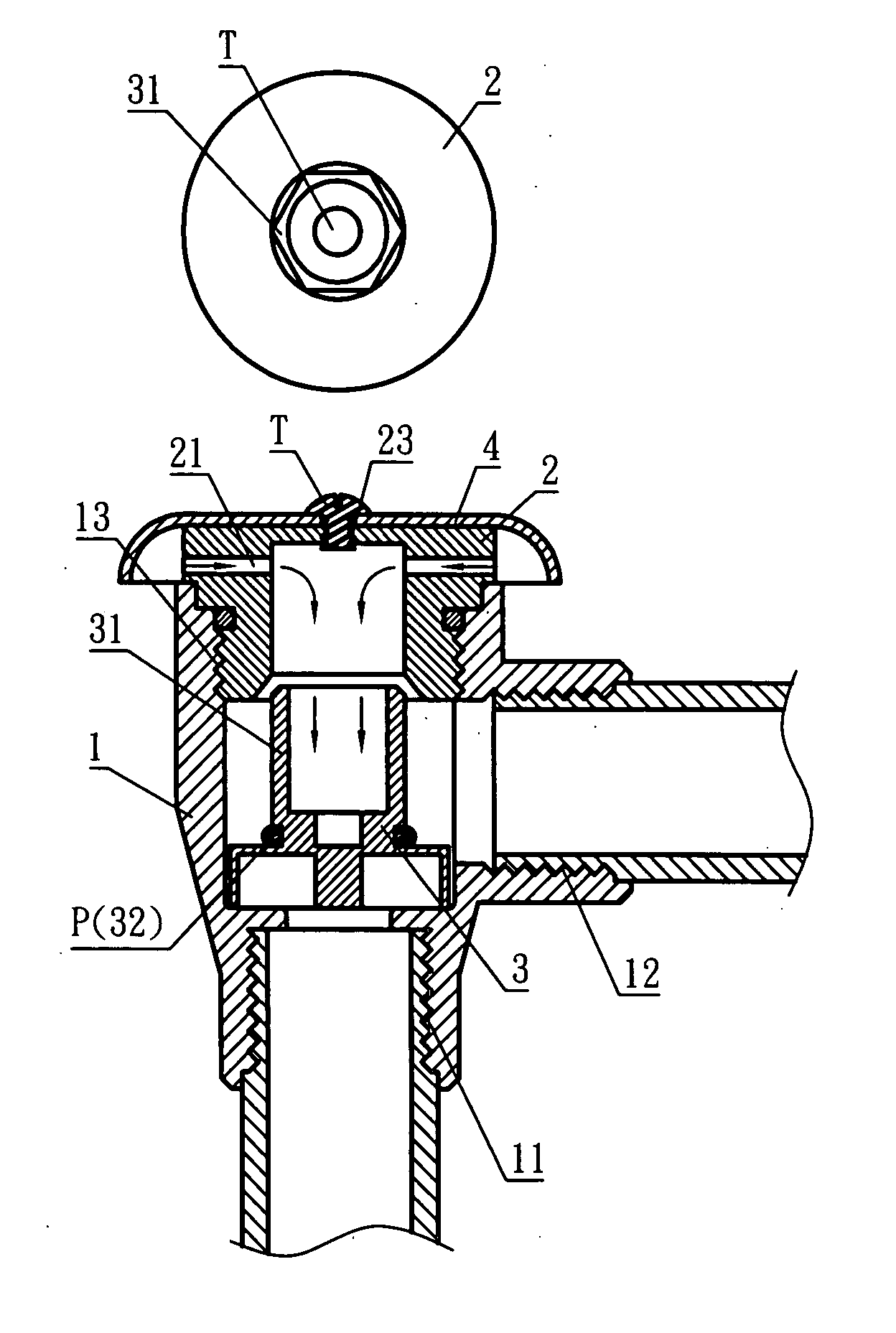

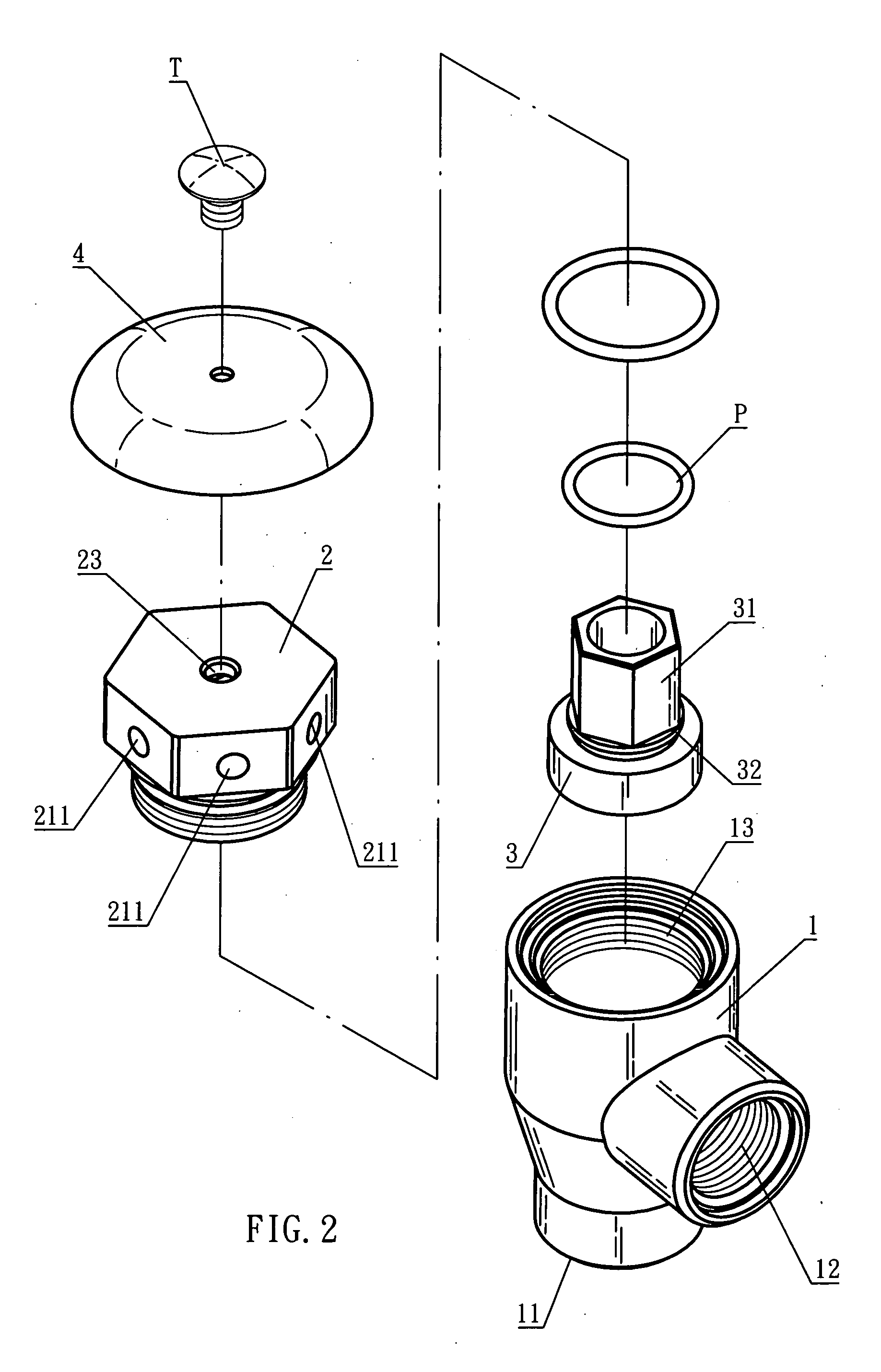

[0013] Referring to the FIG. 2 and FIG. 3, the present invention is to put the screw locking end 31 on the both sides of the water faucet 3 through the shutter S of the granite counter to connect the locking unit 4 and position the water faucet 3 on the shutter S. in which, the locking unit 4 is composed of a locking screw cap 41 for the screw locking end 31, and a packing piece 42 locked in the locking screw cap 41 and a non-returning pad 43, and a water supply pipe 45 whose end and packing piece 41 are fixed and extruded outwards from the lockhole 44. It can prevent the water from seeping by means of tightly jointing with the non-returning pad 43 in the locking screw cap 41 after the locking screw cap is screwed on the screw locking end 31 of the water faucet.

[0014] In addtion, referring to the FIG. 4, the water flow is vertically guided by the water supply pipe to the locking screw cap 41 and lockhole 44, and then to the interior of water faucet 3 through the screw locking end 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com