Amusement ride employing a suspended tensioned static cable

a technology of static cable and suspension cable, which is applied in the direction of rope railways, transportation and packaging, and ways, can solve the problems of reduced braking effectiveness of pad fabricated of homogenous materials, susceptible to structural fatigue failure, etc., and achieves the effects of reducing the chance of operator error, preventing damage to the nose of the trolley, and reducing the cost and complexity of the brake assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

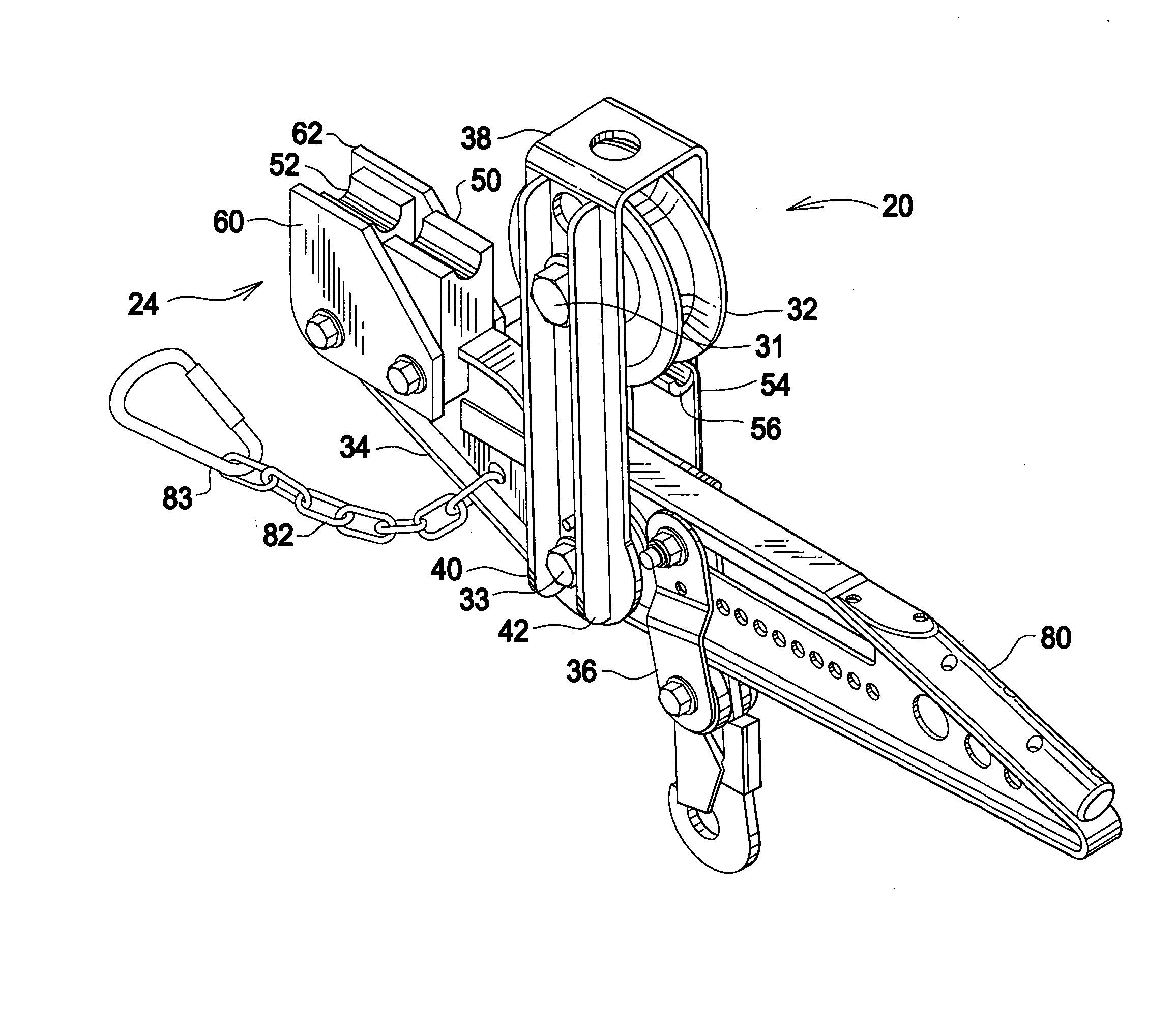

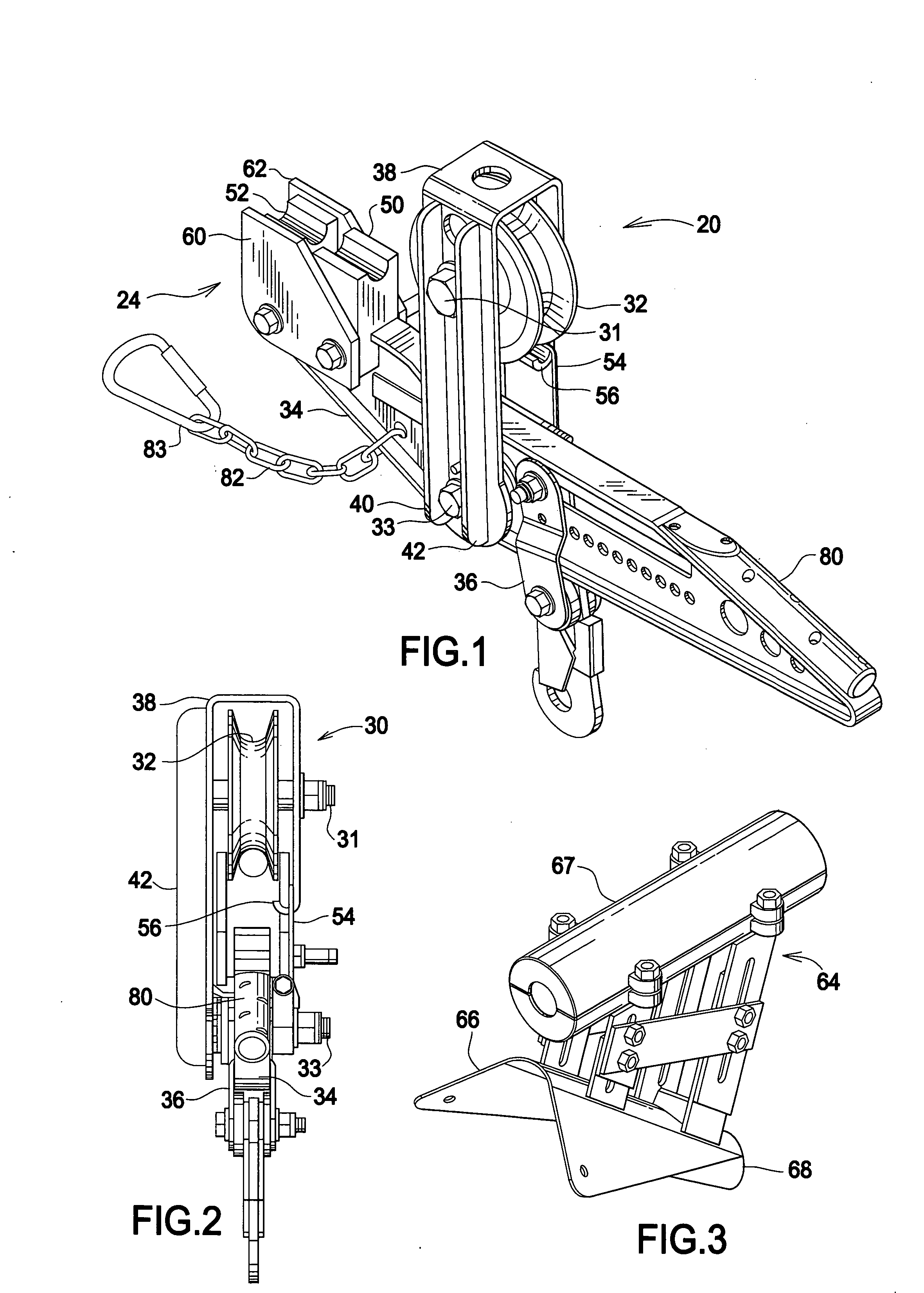

[0008] Referring now to FIGS. 1 and 2, there is shown a trolley 20 for use in suspended static cable ride systems of the type described in the above-cited reference. Trolley 20 includes a wheel assembly 30 having a cable wheel 32, a brake arm 34 to which a brake assembly 24 is attached, and a track guide 36 to which a rider's harness is attached. Wheel assembly 30 further includes a sheave plate 38 having a generally U-shaped inverted configuration. Cable wheel 32 is mounted for rotation within and near the top of sheave plate 38 by means of a bolt 31. A frontal leg of sheave plate 38 is in turn mounted to brake arm 34 by means of a bolt 33, about which sheave plate 38 is free to pivot. Sheave plate 38 is preferably spring-biased at bolt 33 so that its quiescent position is as illustrated in FIGS. 1 and 2, generally perpendicular to brake arm 34. A pair of spaced apart, parallel, vertical channel members 40, 42 are attached to the outer surface of the frontal leg of sheave plate 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com