Reducing oxidation of phase change memory electrodes

a phase change memory and electrode technology, applied in the direction of bulk negative resistance effect devices, semiconductor devices, electrical equipment, etc., can solve the problems of significant resistance increase, defective products, and add to the cost of manufacturing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

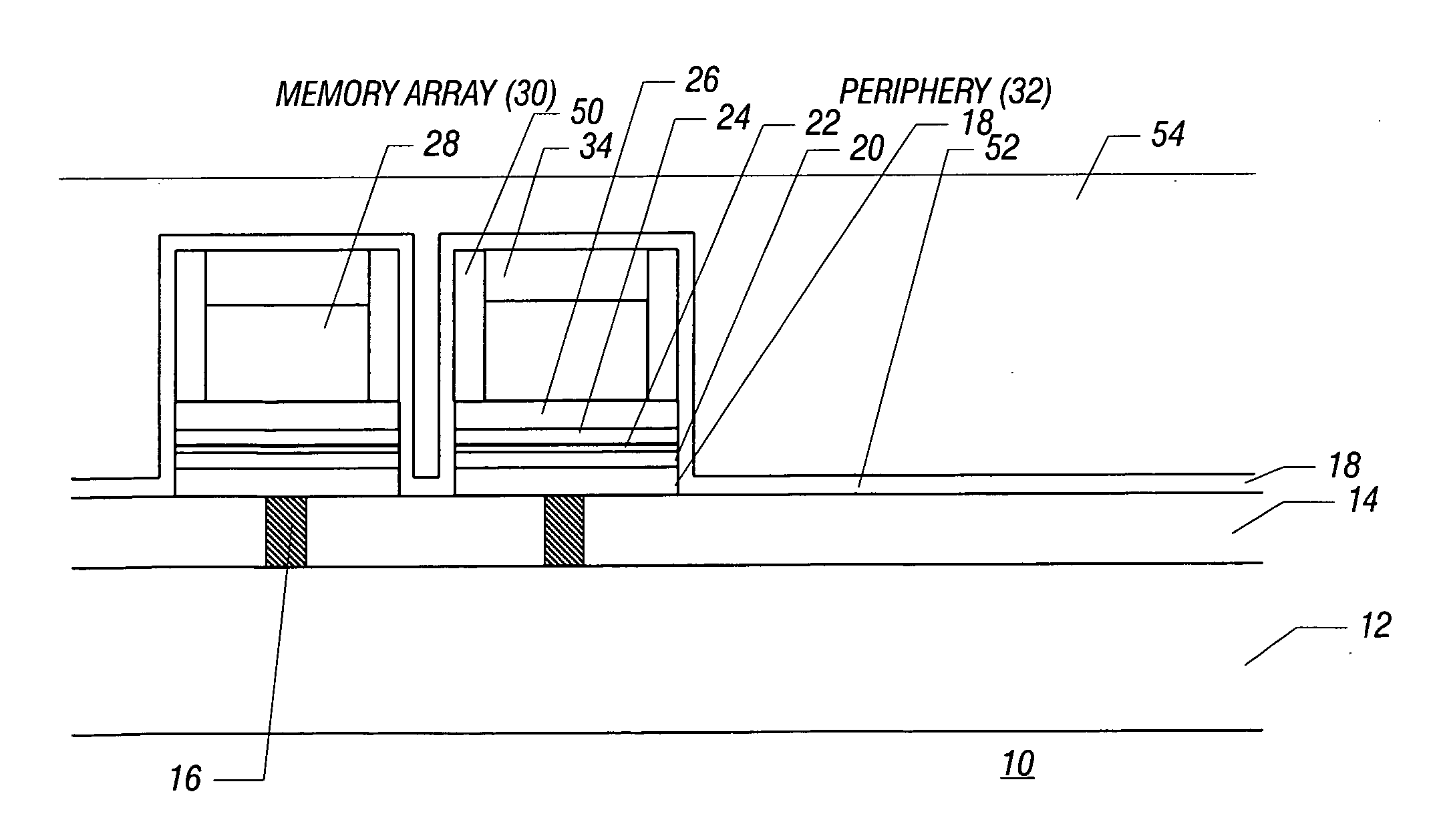

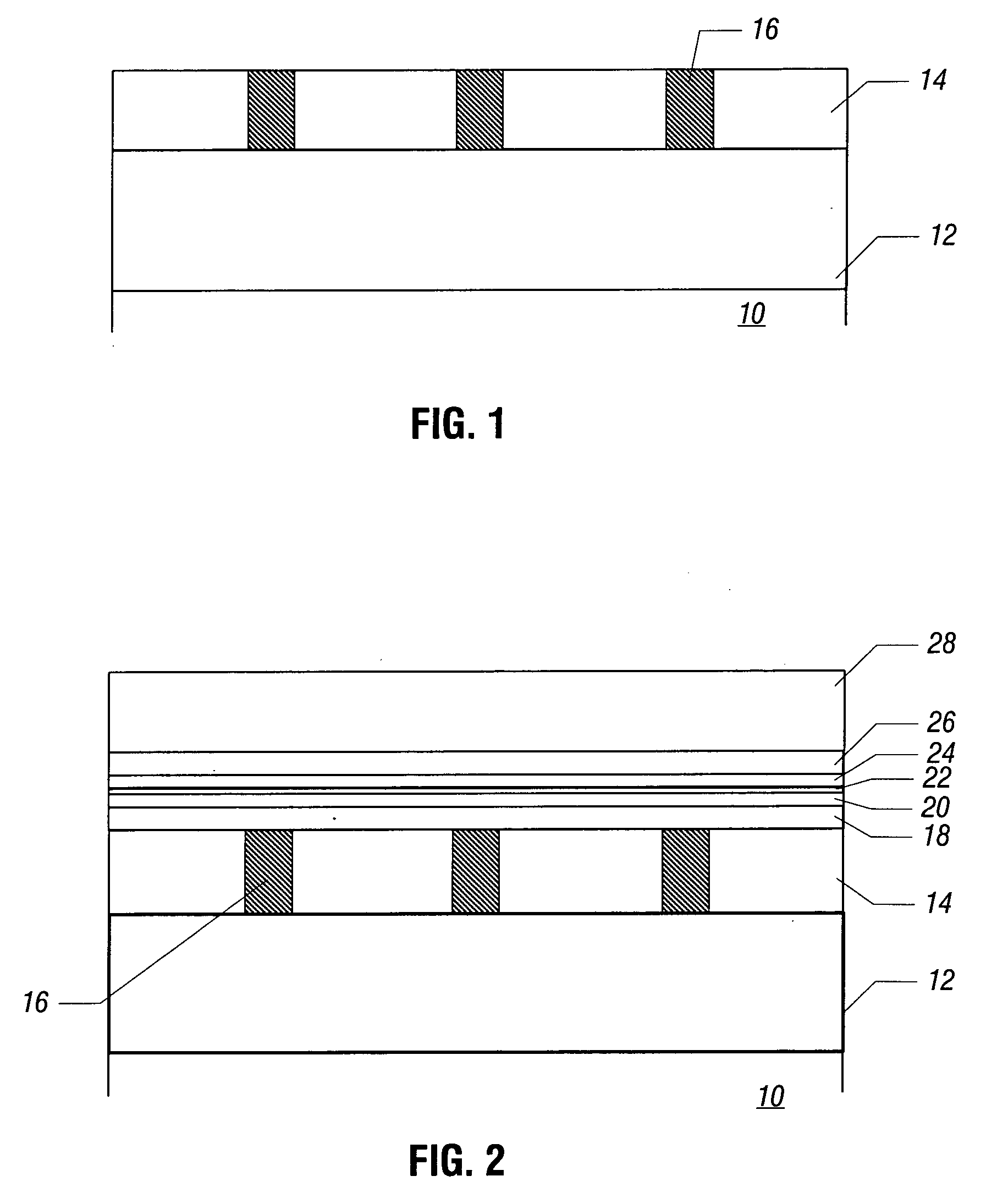

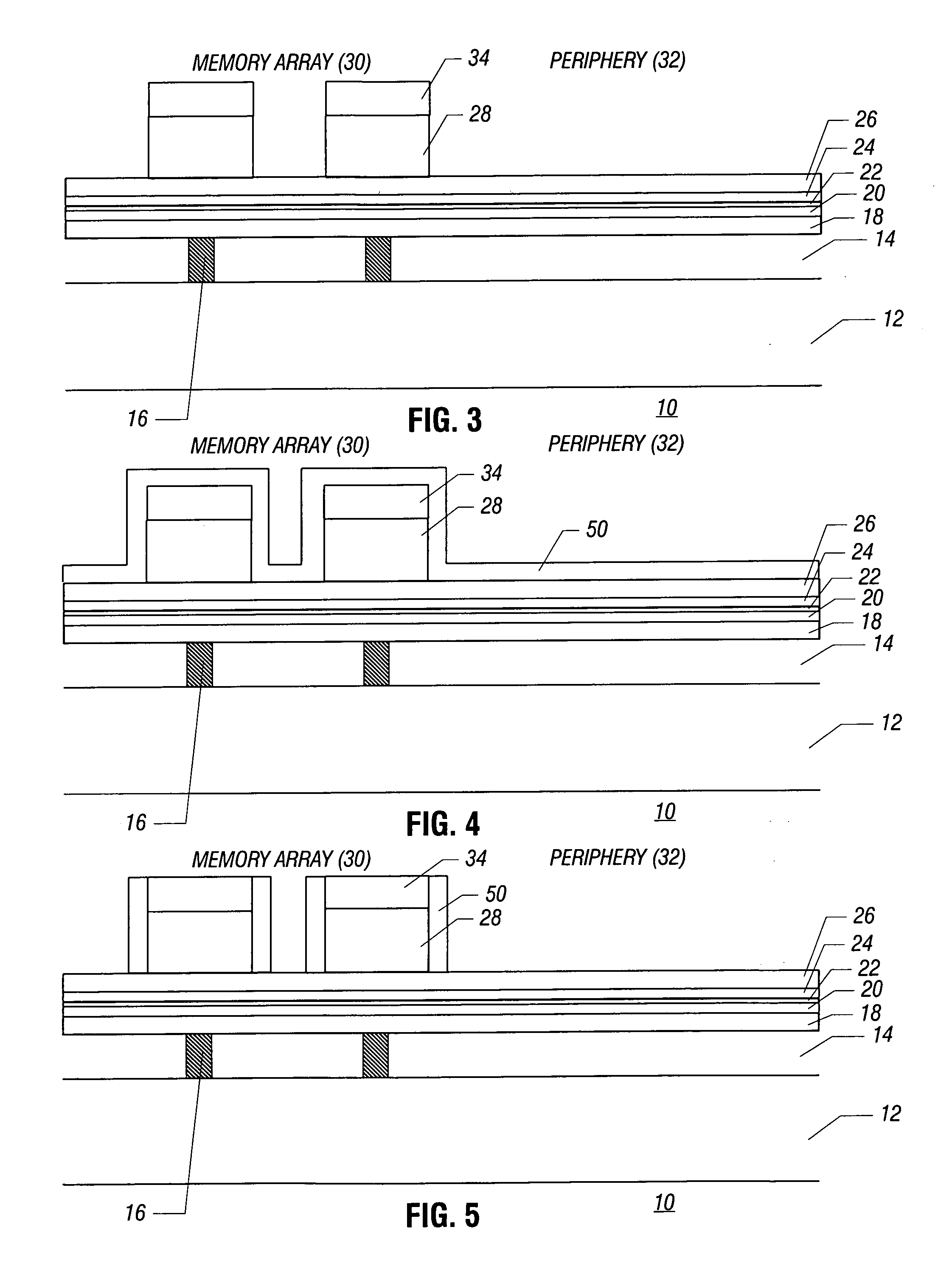

[0013] In accordance with some embodiments of the present invention, oxygen infiltration may be reduced. Oxygen infiltration causes oxidation of the lower electrode, adversely affecting the performance of phase change memories. One modality for such oxidation is for oxygen to diffuse through a chalcogenide layer overlying the lower electrode. When that oxygen diffuses through and reaches the lower electrode it causes oxidation of that oxidizable lower electrode. To prevent such infiltration, a barrier layer may be utilized in one embodiment of the present invention, which is applied under appropriate circumstances to facilitate other process steps while still protecting the lower electrode, in some embodiments.

[0014] In one embodiment, memory elements may comprise a phase change material. In this embodiment, the memory may be referred to as a phase change memory. A phase change material may be a material having electrical properties (e.g. resistance, capacitance, etc.) that may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com