Embedded metal reinforced structural element and methods for design and manufacture

a technology of embedded metal and structural elements, applied in the field of structural materials, can solve the problems of insufficient disclosure of non-metallic reinforcement properties of the prior art, insufficient evaluation of variability effects, and insufficient disclosure of information to permit computer modeling of stresses and deflection of beams, etc., to achieve the effect of improving plurality of properties and diffusing modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Preferred Embodiment

[0085] It is not possible to describe a preferred embodiment of EMRSE technology because the statement of the problem (specifications) establishes the form and function of the structural element and the details of the design and manufacturing processes used to obtain an optimal EMRST. Many types of reinforced beams could be built to meet most functional specifications for simple beams with simple loading configurations and lengths required for conventional structures. However, advanced structural engineering and mechanics of materials technology, becoming more widely understood and used today, are required to solve complex problems and provide optimal EMRSE

Methods

[0086] The procedures used in solving engineering problems will vary among individuals and will vary according to the type and complexity of problem. In general, the methods of the present invention are based on those suggested in Section B.2 of Gere. (Ref.2) Additional consideration was given to the r...

examples

[0098] The present invention can be further described by the following specific examples:

example i

Computer Model Verification with Benchmark Data

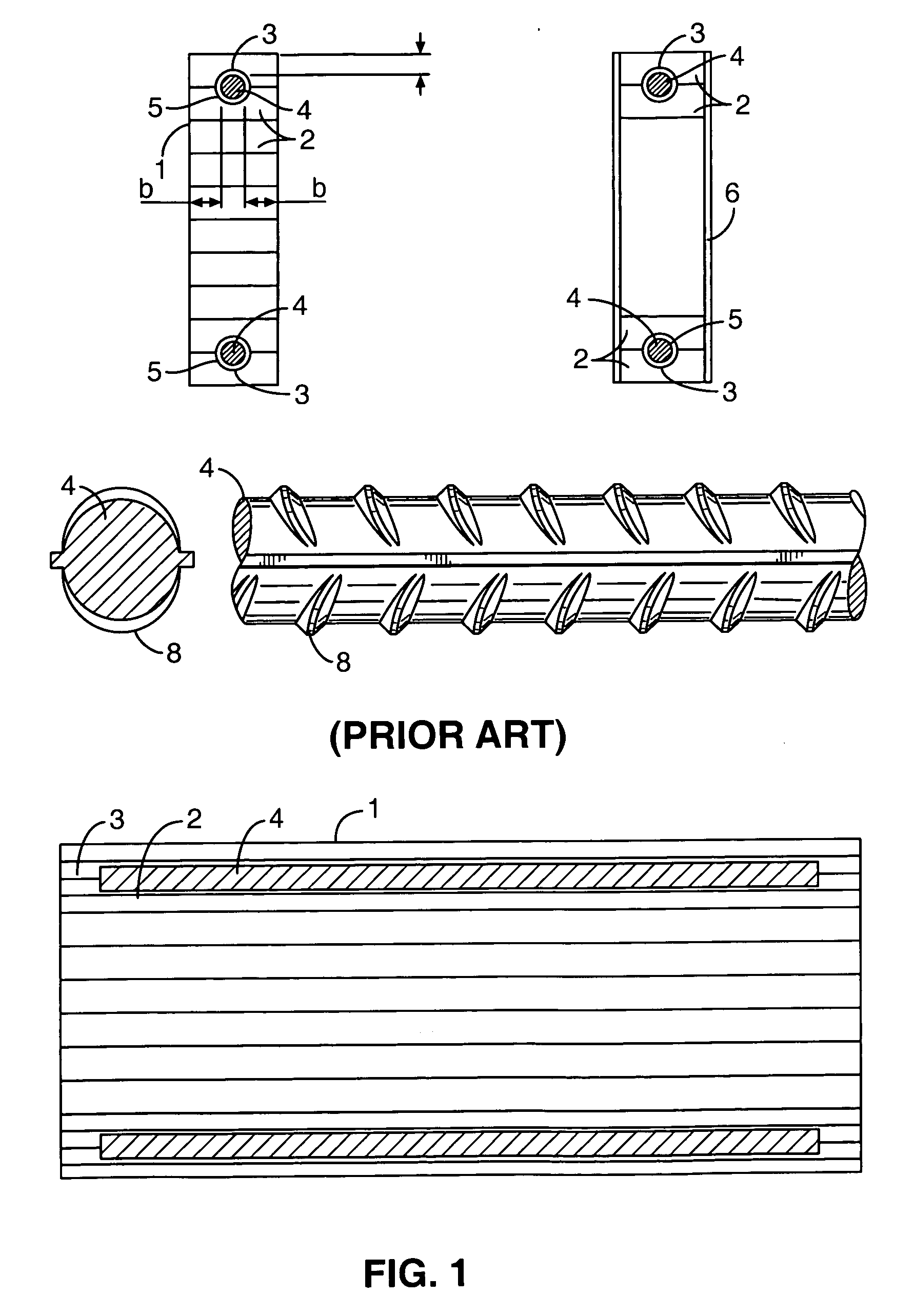

[0099]FIG. 1 shows the prior art beam as disclosed in the '366 patent. A computer model was made for this beam using an unpublished computer code designated herein as TRANSFORM X, which is a research program of limited capability that does not use finite element methods. TRANSFORM X is an adaptation of a computer code designed for other purposes and is discussed by Hernandez. (Ref. 15). Cheng reported good agreement between the method of Hernandez and his finite element methods. (Ref. 20) Because TRANSFORM X is a research code and has not been verified for general use, it was necessary to benchmark it for use in this specific application, and Gardner's data was the only available data relevant to embedded metal reinforced glue laminated beams. Gardner did not report calculated or measured stress data and without these data he was apparently unable to perform a failure mode and effects analysis. TRANSFORM X has the capability to analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com