Overhead Suspended Transportation System and Method

a transportation system and suspension technology, applied in the field of transportation systems, can solve the problems of limited speed, limited propulsion and braking force generated in the trucks, and difficulty in detaching or exchanging the car body, so as to reduce the total number of wheels required to carry the train, reduce the weight, and ensure the effect of accurate electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will now be described more fully with reference to the accompanying drawings in which preferred embodiments of the invention are shown and described. It is to be understood that the invention may be embodied in many different forms and should not be construed as limited to the illustrated embodiments set forth herein. Rather, these embodiments are provided so that this disclosure may be thorough and complete, and will convey the scope of the invention to those skilled in the art.

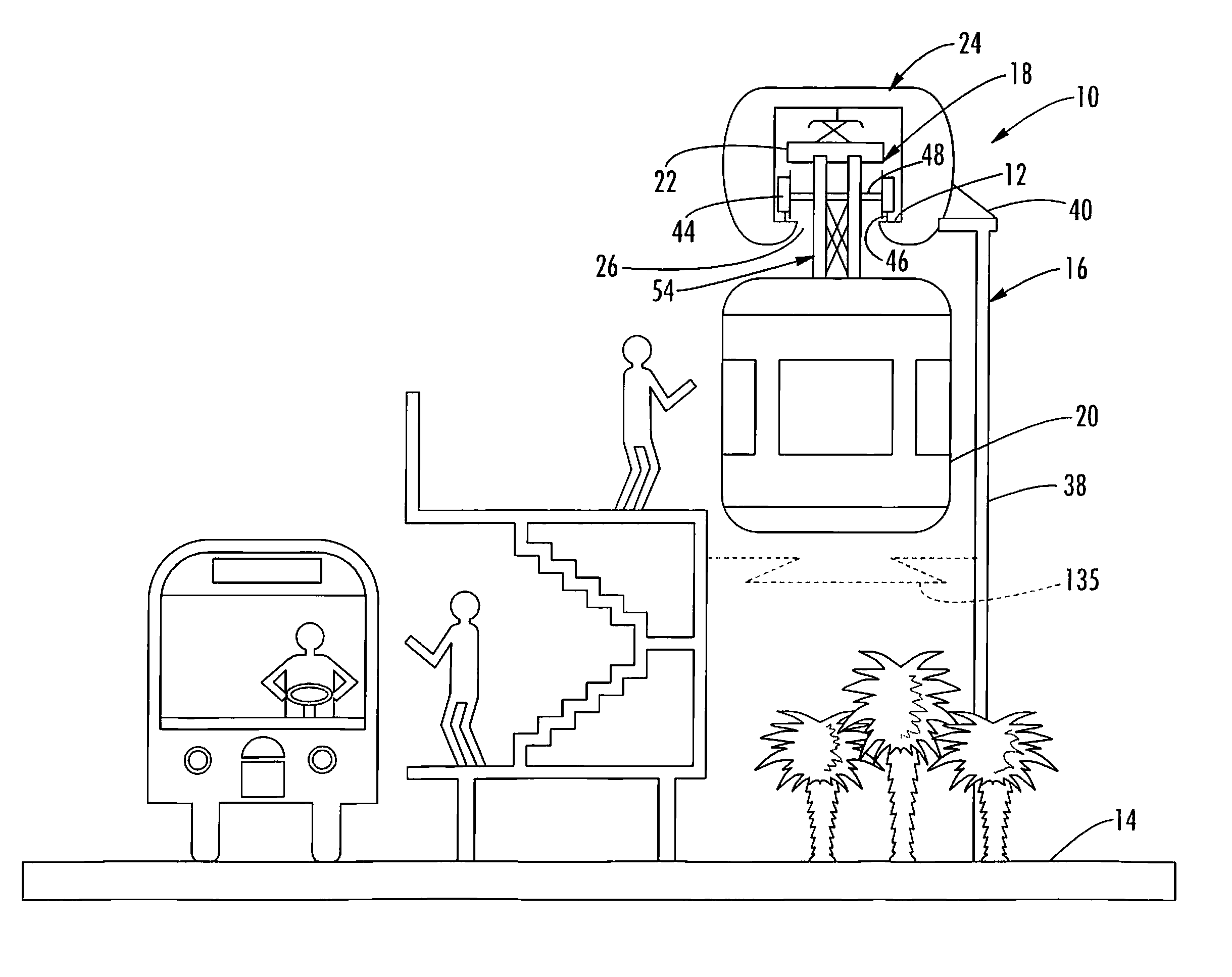

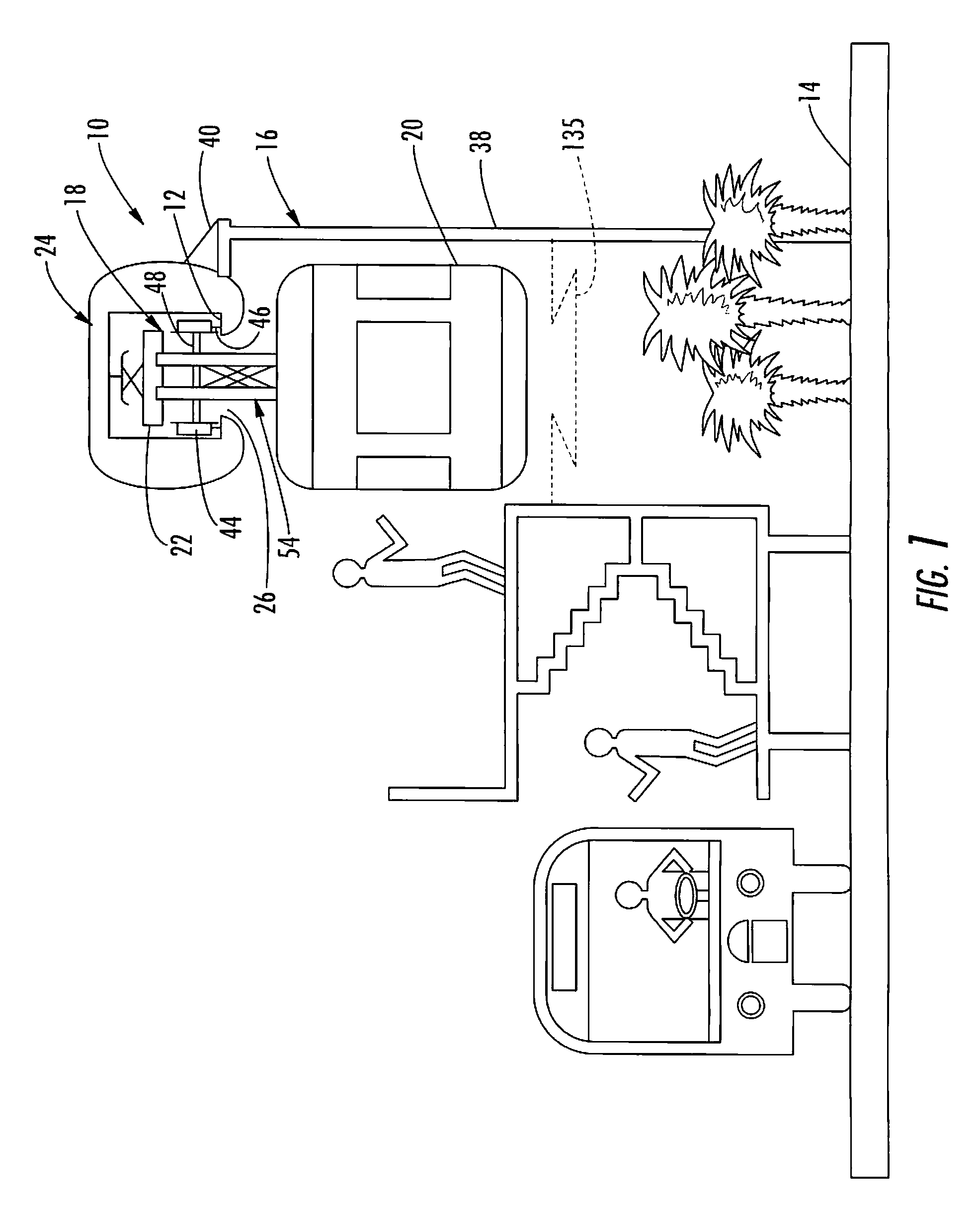

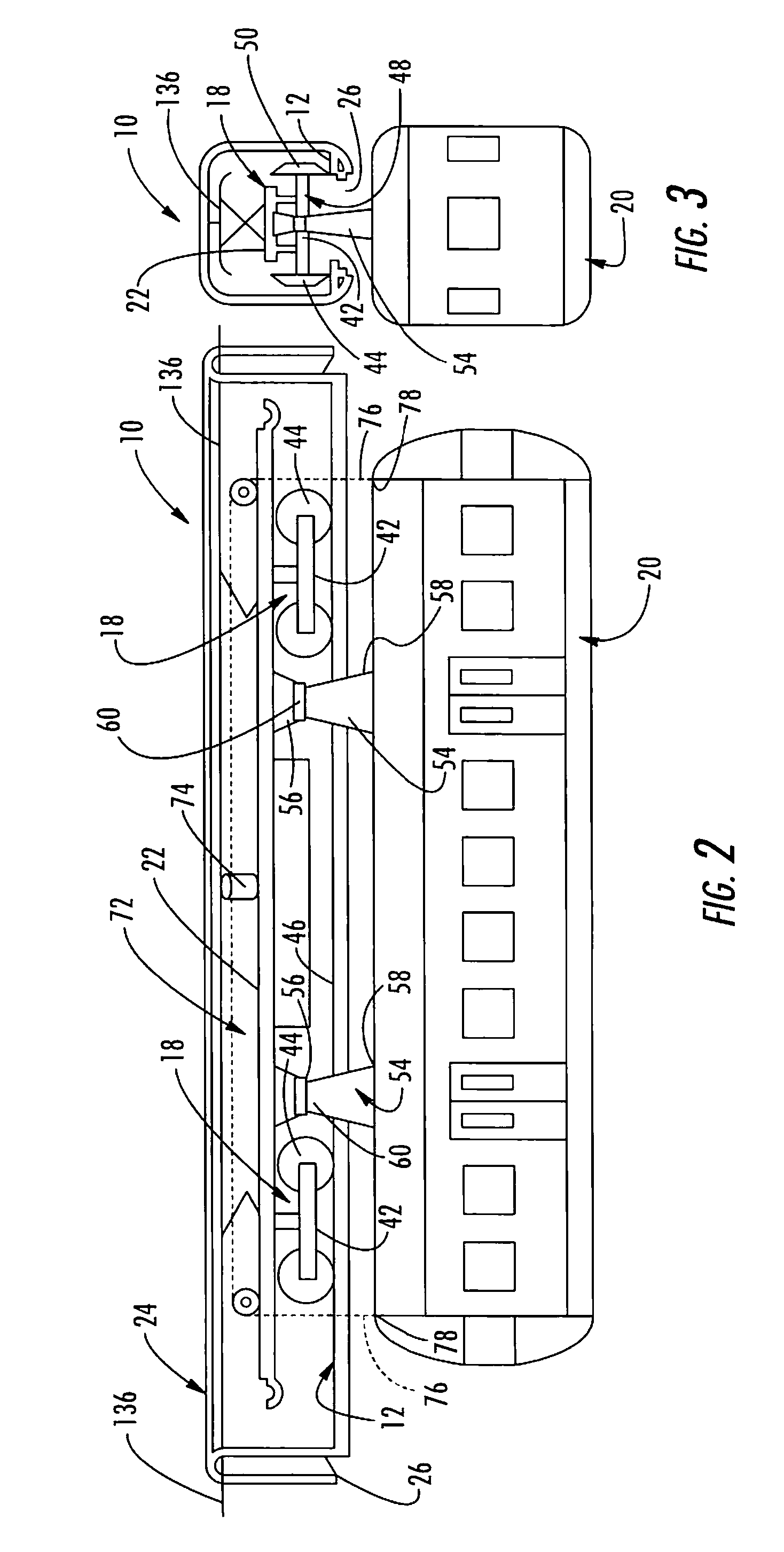

[0044] With reference initially to FIG. 1, a transportation system 10 following the teachings of the present invention may include a running surface 12 suspended above ground level 14 by a support structure 16. A truck 18, also known as a bogie, is operable along the running surface 12. As herein described by way of example, a car body 20 may be suspended from a chassis 22 carried by the truck 18 for suspending the car body above the ground level 14. As will be further described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com