Semiconductor image sensor and method for fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

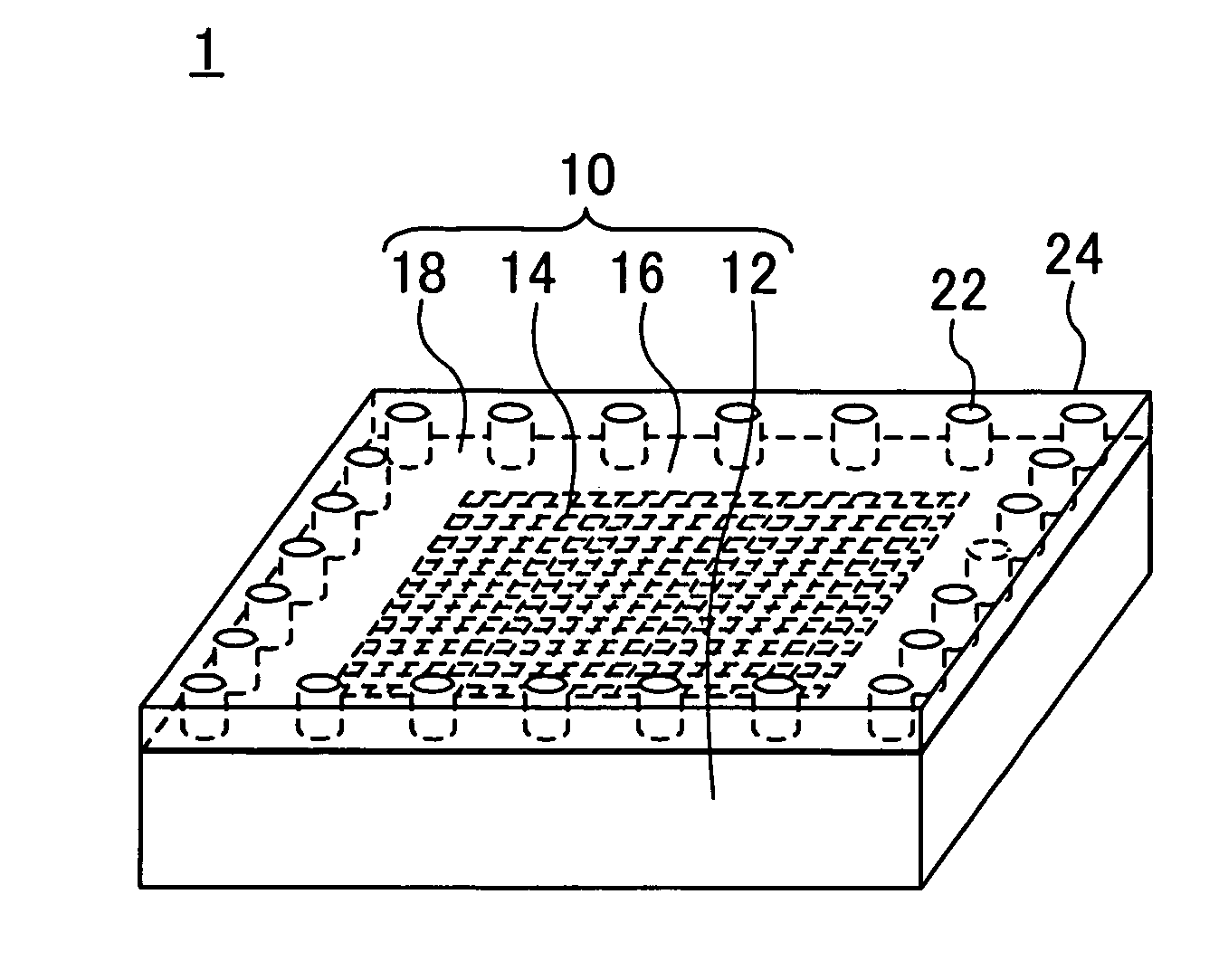

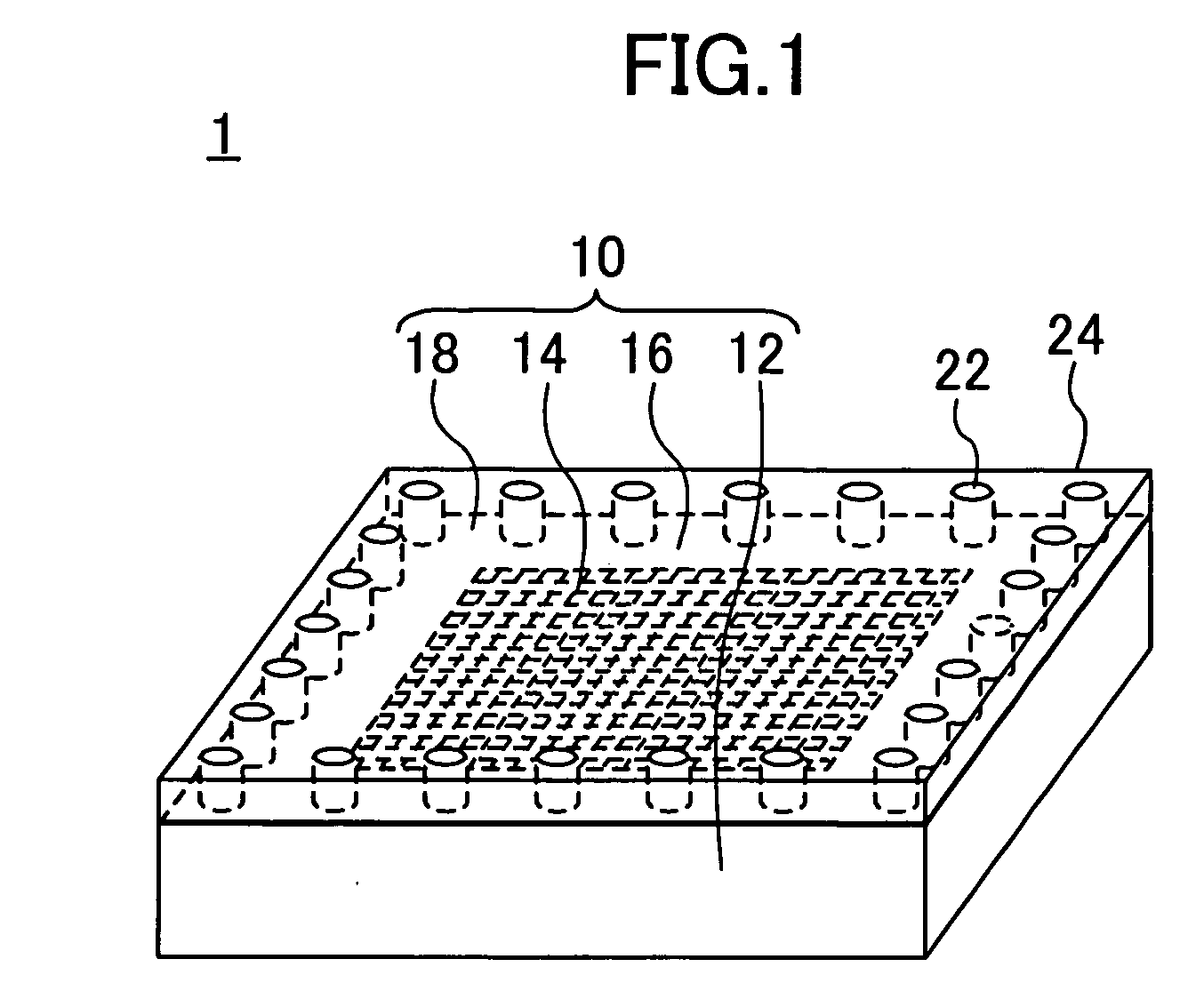

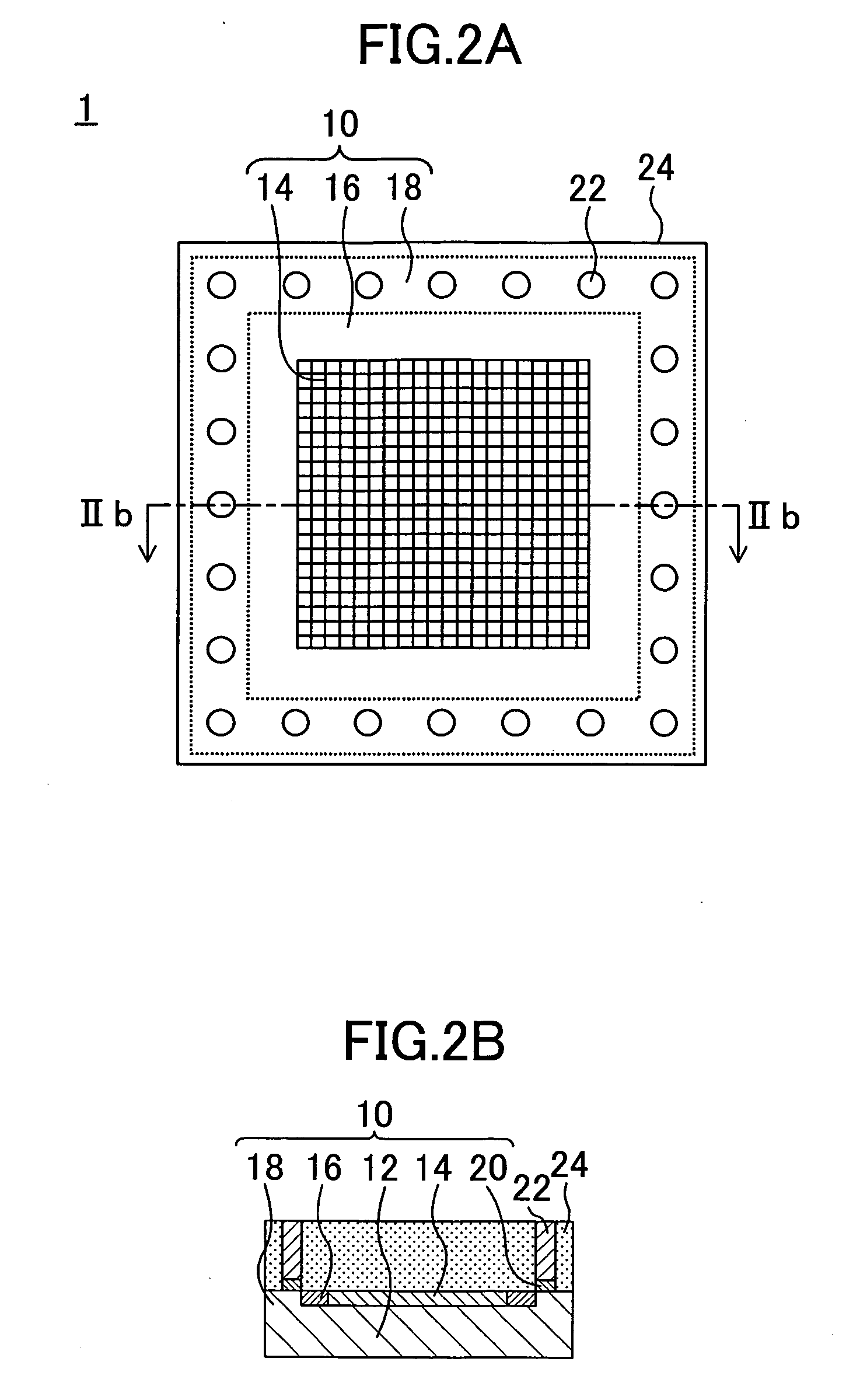

[0033]FIG. 1 is an oblique view schematically illustrating the entire structure of a semiconductor image sensor according to a first embodiment of the present invention. FIGS. 2A and 2B are a plan view and a cross-sectional view taken along the line IIb-IIb, respectively, each illustrating the semiconductor image sensor of this embodiment.

[0034] As shown in FIGS. 1 and 2, the semiconductor image sensor 1 of this embodiment includes a semiconductor imaging element 10, cylindrical electrodes 22, and a transparent resin layer 24 formed on the entire upper surface of the semiconductor imaging element 10.

[0035] The semiconductor imaging element 10 includes a semiconductor substrate 12, an imaging area 14 formed on the semiconductor substrate 12, a peripheral circuit area 16 surrounding the imaging area 14, and an electrode area 18 including electrode terminals 20 for establishing connection with an external circuit or circuits. The cylindrical electrodes 22 are formed on the electrode ...

second embodiment

[0064]FIGS. 5A and 5B are a plan view and a cross-sectional view taken along the line Vb-Vb, respectively, each schematically illustrating the entire structure of a semiconductor image sensor according to a second embodiment of the present invention. In FIGS. 5A and 5B, the same members as those in the semiconductor image sensor of the first embodiment shown in FIG. 2 are identified by the same reference numerals.

[0065] The semiconductor image sensor 2 of this embodiment differs from the semiconductor image sensor 1 of the first embodiment in that an antireflection film 32 is formed around the side face (i.e., the perimeter) of each electrode terminal 20 and of each cylindrical electrode 22. In the other respects, the semiconductor image sensor 2 of this embodiment has the same structure as the semiconductor image sensor 1 of the first embodiment, and the descriptions of the same members will be thus omitted herein.

[0066] The antireflection films 32, which are made of a material s...

third embodiment

[0073]FIGS. 7A and 7B are a plan view and a cross-sectional view taken along the line VIIb-VIIb, respectively, each schematically illustrating the entire structure of a semiconductor image sensor according to a third embodiment of the present invention.

[0074] As shown in FIGS. 7A and 7B, the semiconductor image sensor 3 of this embodiment includes a semiconductor imaging element 10, a transparent resin adhesive 38 applied onto the upper surface (the circuit-formation surface) of an imaging area 14 in the semiconductor imaging element 10, a transparent sheet 34 bonded to the upper surface of the imaging area 14 with the transparent resin adhesive 38, and an antireflection film 36 provided on the perimeter (i.e., the side faces) of the transparent sheet 34.

[0075] As in the first embodiment, the semiconductor imaging element 10 includes a semiconductor substrate 12, and the imaging area 14, a peripheral circuit area 16, and an electrode area 18 including electrode terminals 20, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com