Ophthalmic lens package and methods of its use

a technology for ophthalmic lenses and lenses, applied in the field of ophthalmic lens packages, can solve the problems of destroying both the user and the lens, affecting the user's vision, and affecting the use of the lens,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

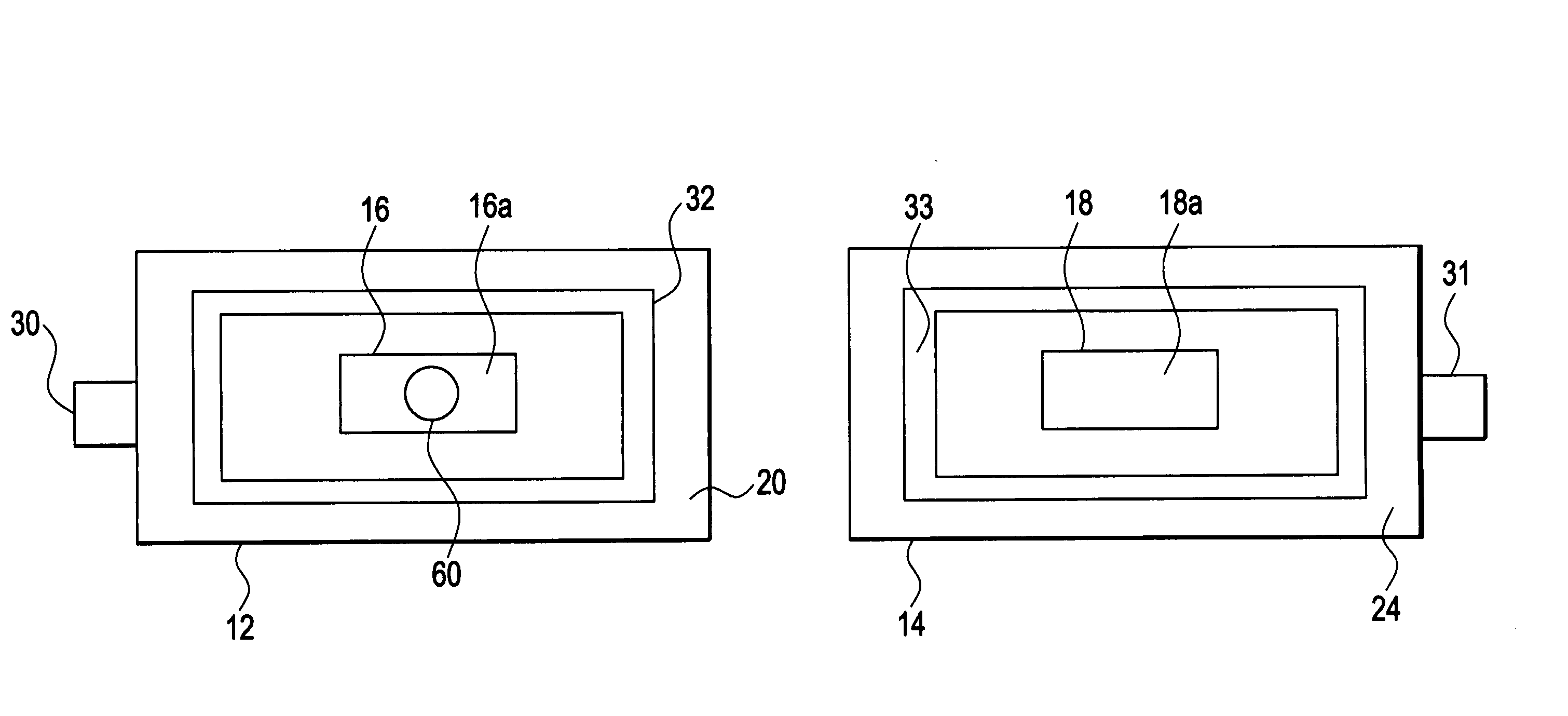

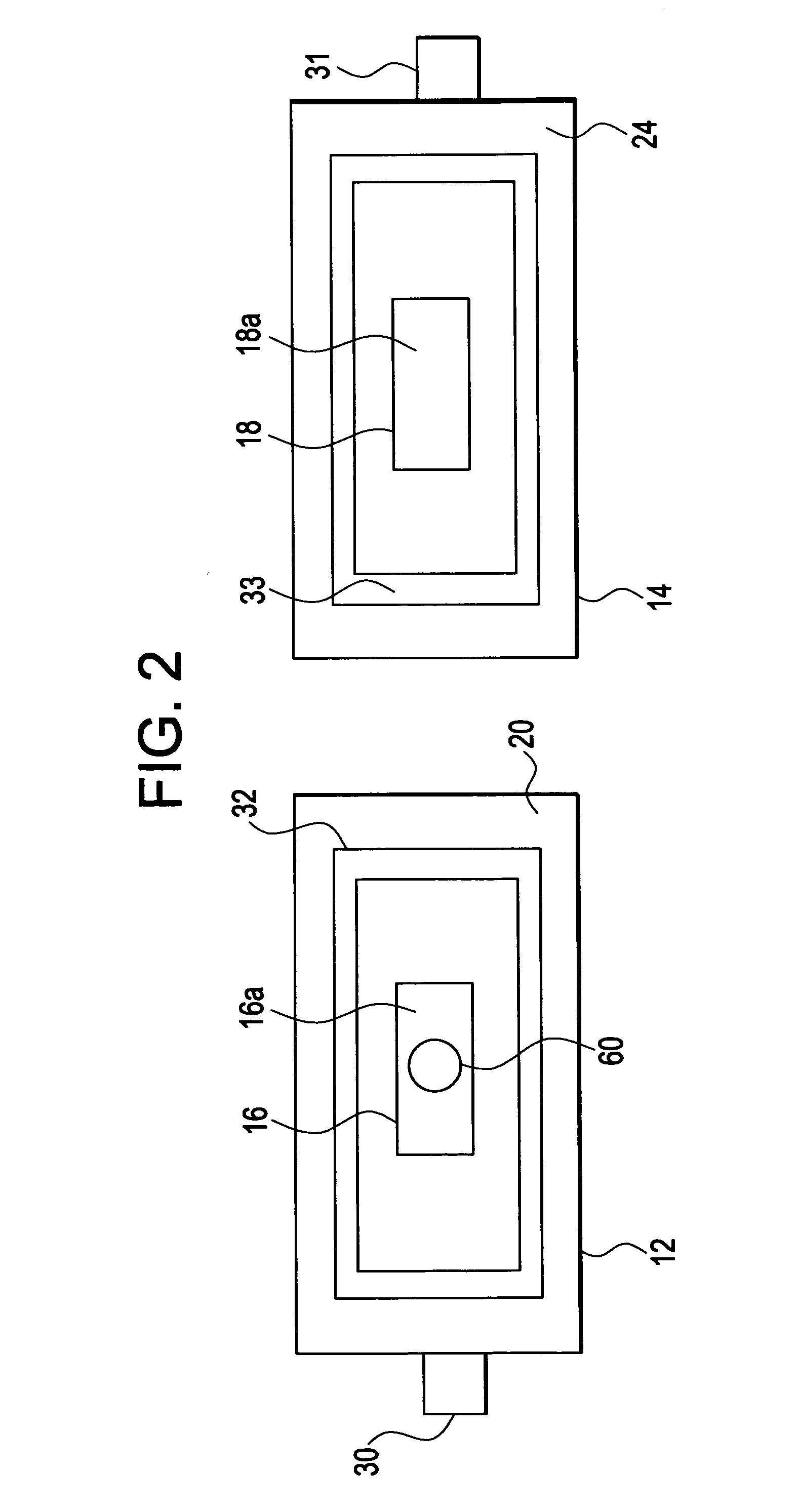

[0010] The invention includes an ophthalmic lens package, comprising a first strip member comprising a first side, a second side, and a first absorbent member, wherein said first absorbent member is attached to a portion of said first side of said first strip member; a second strip member comprising a first side, a second side, and a second absorbent member wherein said second absorbent member is attached to a portion of said first side of said second strip member; said first and second strip members being removably attached each other when said package is closed position, said first and second absorbent members being adapted to receive and house an ophthalmic lens and an amount of solution when said package is closed.

[0011] As used herein, “ophthalmic lens” refer to a device that resides on the eye, including but not limited to soft contact, lenses, hard contact lenses, intraocular lenses, overlay lenses, preferably soft contact lenses.

[0012] Referring to FIGS. 1, 2 and 3, a cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com