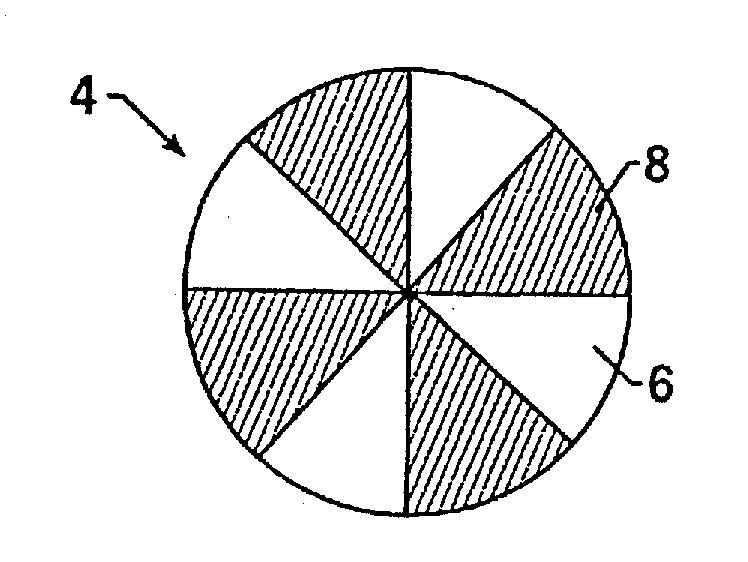

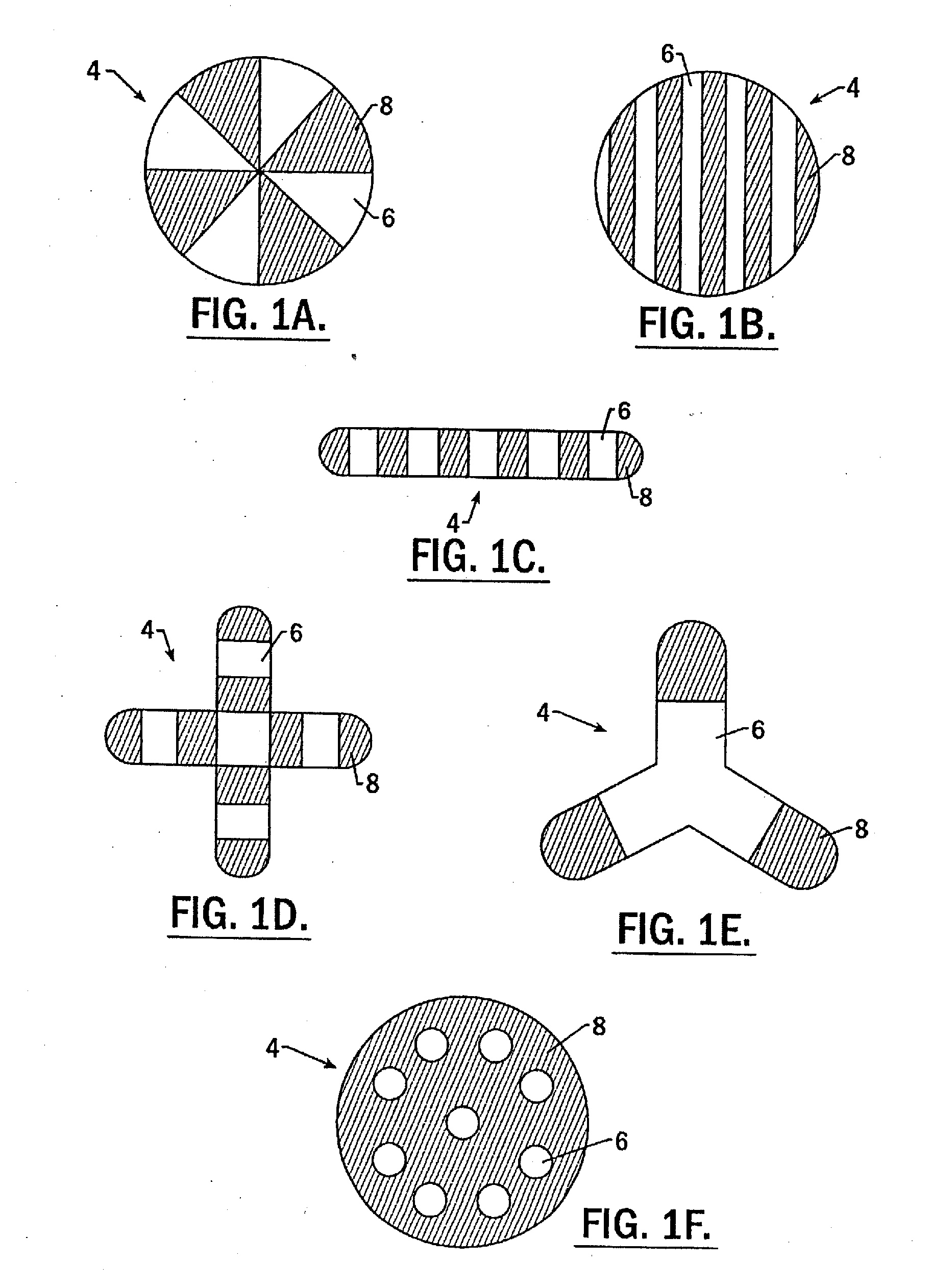

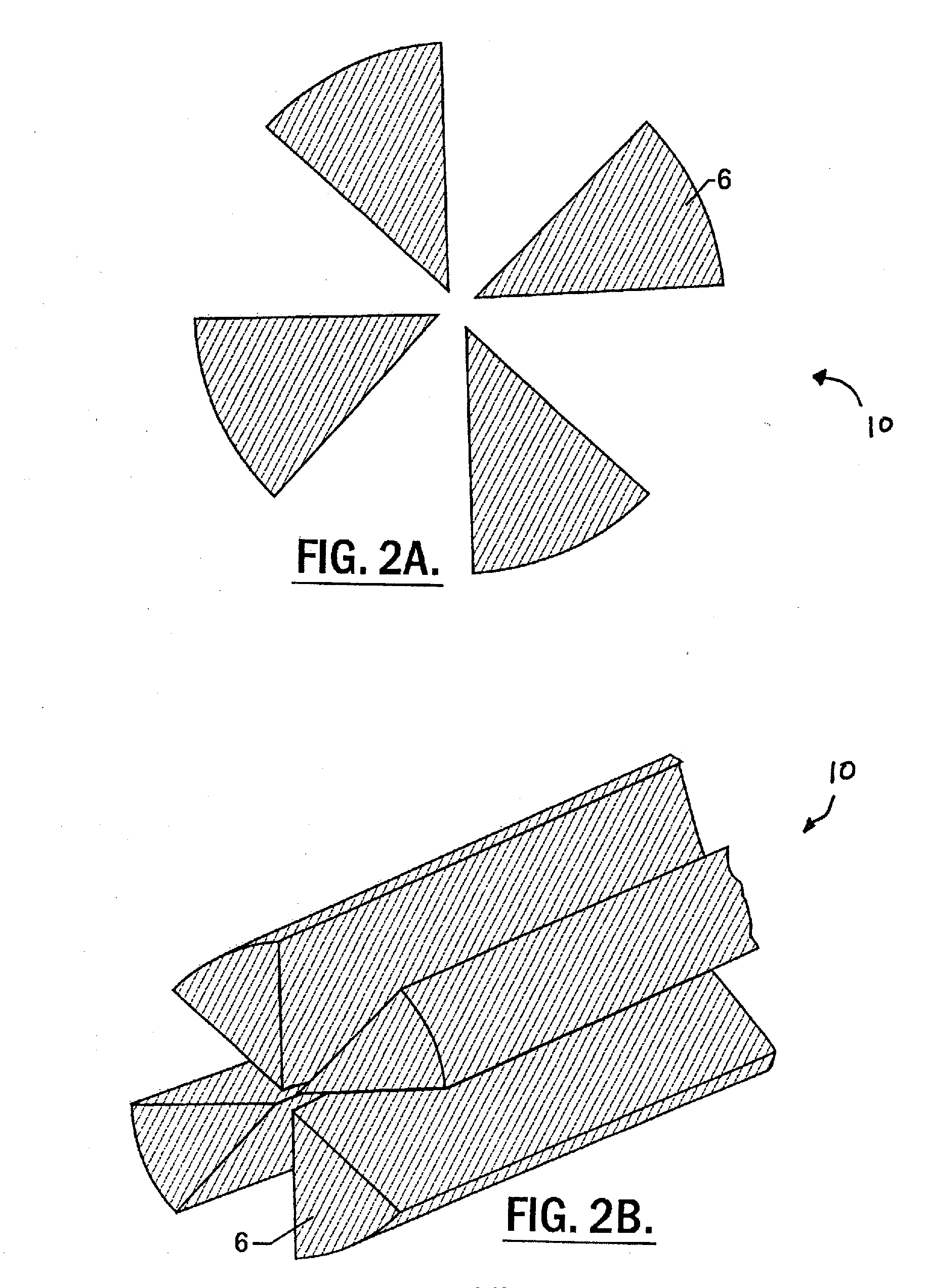

Soluble Microfilament-Generating Multicomponent Fibers

a multi-component fiber and microfilament technology, applied in the field of microfilament generation multi-component fibers, can solve the problems of not naturally degrading, general cost-effective recycling of articles containing nonwoven fabrics, and disposal of products containing such fibers, and achieve the effect of easy dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0058] In a bicomponent fiber melt-spinning process, one extruder was fed with dried pellets of NATUREWORKS™ 6201D polylactic acid (PLA) from Cargill Dow LLC, and the second extruder was fed with dried pellets of EXCEVAL™ polyvinyl alcohol (PVOH) from Kuraray. The PLA was melted and extruded at 245° C. and pumped by a gear pump into a spinneret assembly. The PVOH was melted and extruded at 255° C. and pumped into the same spinneret assembly. Polymer distribution plates in the spinneret assembly delivered the polymers independently through multiple flow paths to positions in each spinneret backhole such that in each, the PLA formed islands in the contiguous “sea” of PVOH, forming a polymer-to-polymer cross sectional arrangement that was maintained in the fiber through extrusion through the round capillaries of the spinneret and subsequent solidification in a cross-current air stream, and takeup across rolls and onto a winder at a speed of 815 meters / minute. In each fiber cross sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com