Internal combustion engine component and method for the production thereof

a technology of internal combustion engine and component, which is applied in the direction of machines/engines, mechanical equipment, coatings, etc., can solve the problems of mechanical tension induced, crack formation, and over-the-weight of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

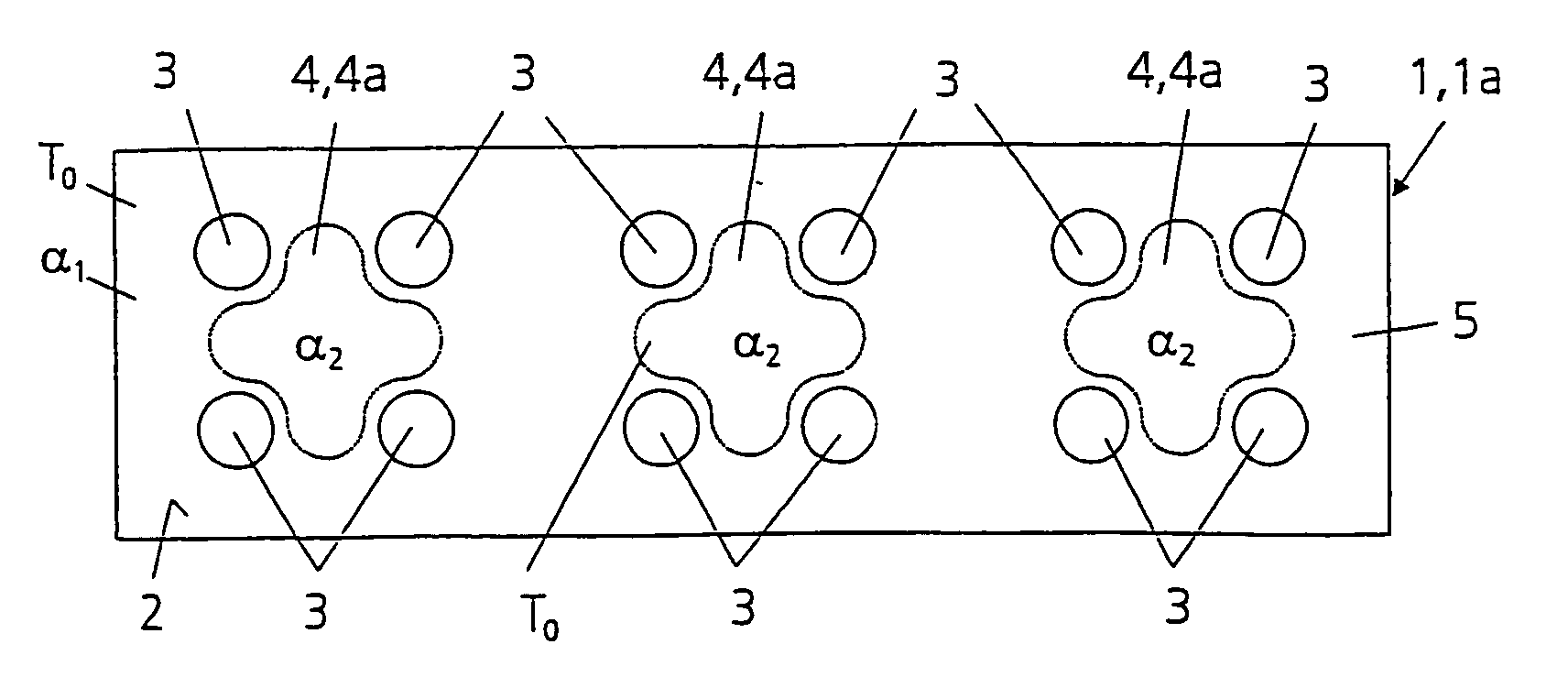

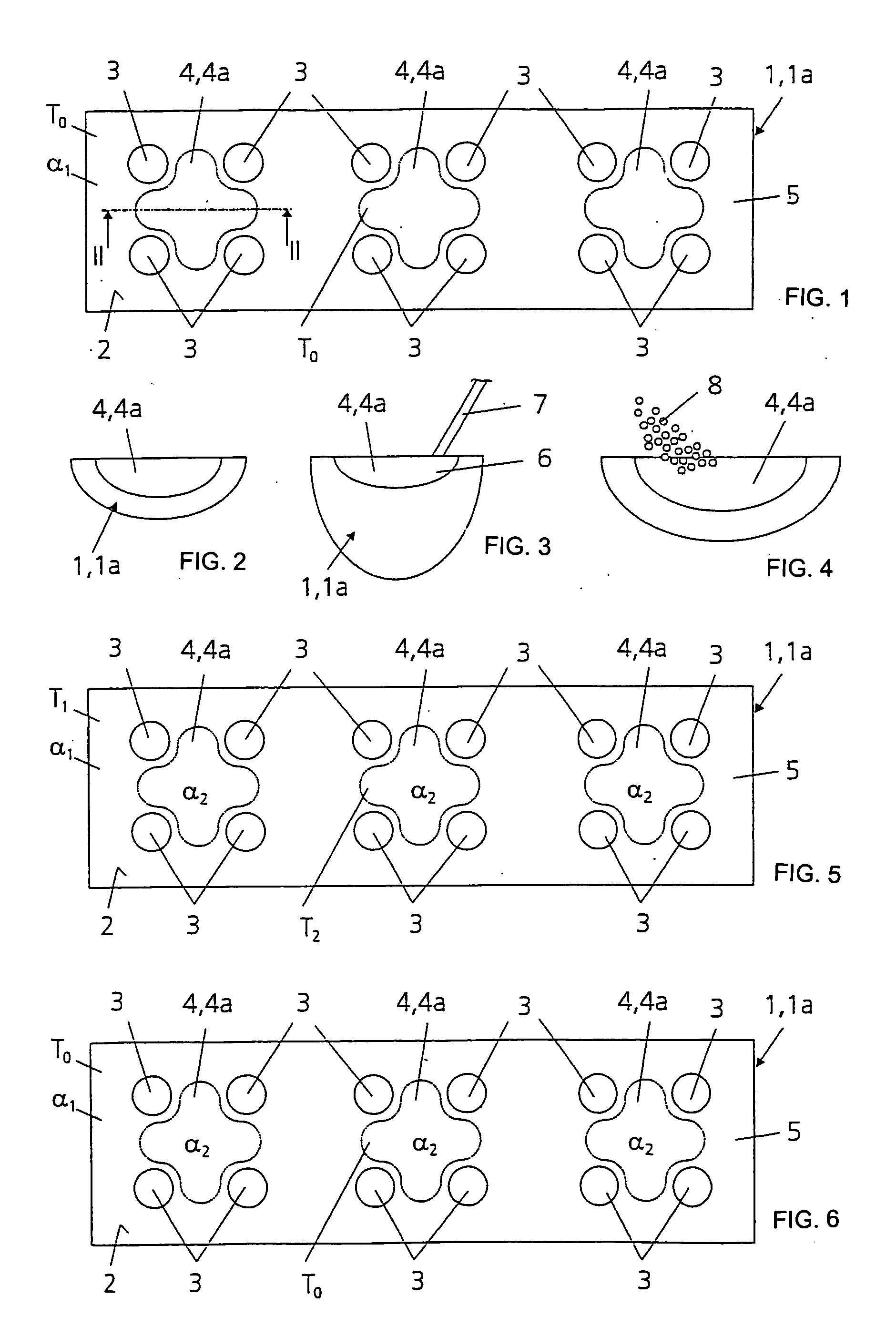

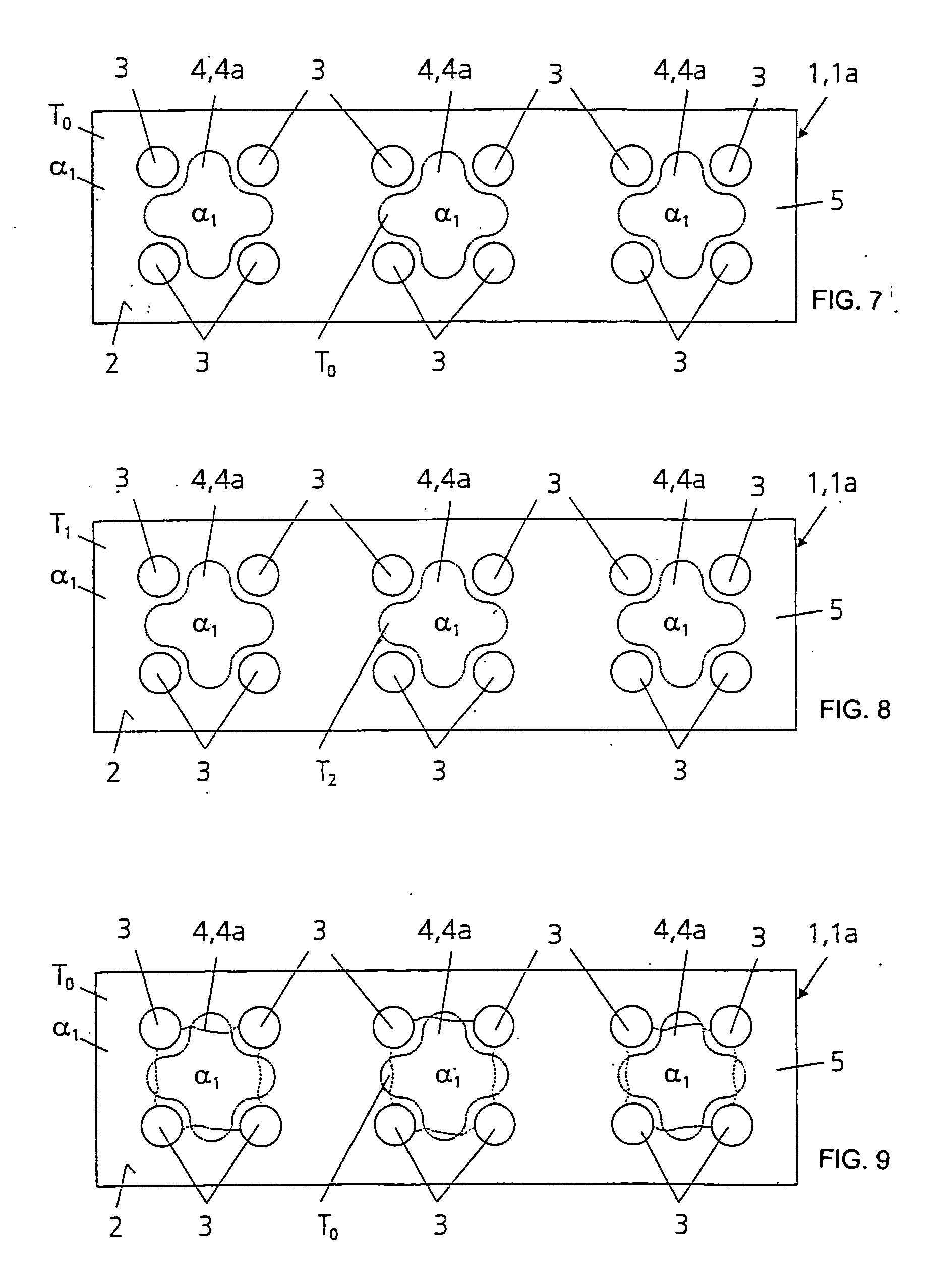

[0024]FIGS. 7, 8 and 9 show a component 1 of an internal combustion engine—not shown in its entirety—as known from the state of the art. The component 1 is in the present case a cylinder head 1a, wherein FIGS. 1, 5 and 6 show a view on the separating surface 2 of the cylinder head 1a. In place of the cylinder head 1a the component 1 could just as well be a piston or another thermally very strongly loaded component of an internal combustion engine.

[0025] The cylinder head 1a includes multiple valve bores 3, between which a thermally higher loaded area 4 is located, which in the following is referred to as the intermediate area 4a. This intermediate area 4a is, during operation of the internal combustion engine, higher thermally loaded than the rest of the component 1 or, as the case may be, than other areas 5 of the component 1. Since the internal combustion engine associated with the cylinder head 1a has three, or as the case may be, six cylinders, a total of three intermediate are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell angle | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com