Cleat for athletic shoe

a technology for athletic shoes and cleats, applied in the field of athletic cleats, can solve the problems of only minimal bracing of cleats, little to counter the above-described and each difficulty, so as to prevent the rotational movement of golfers' feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

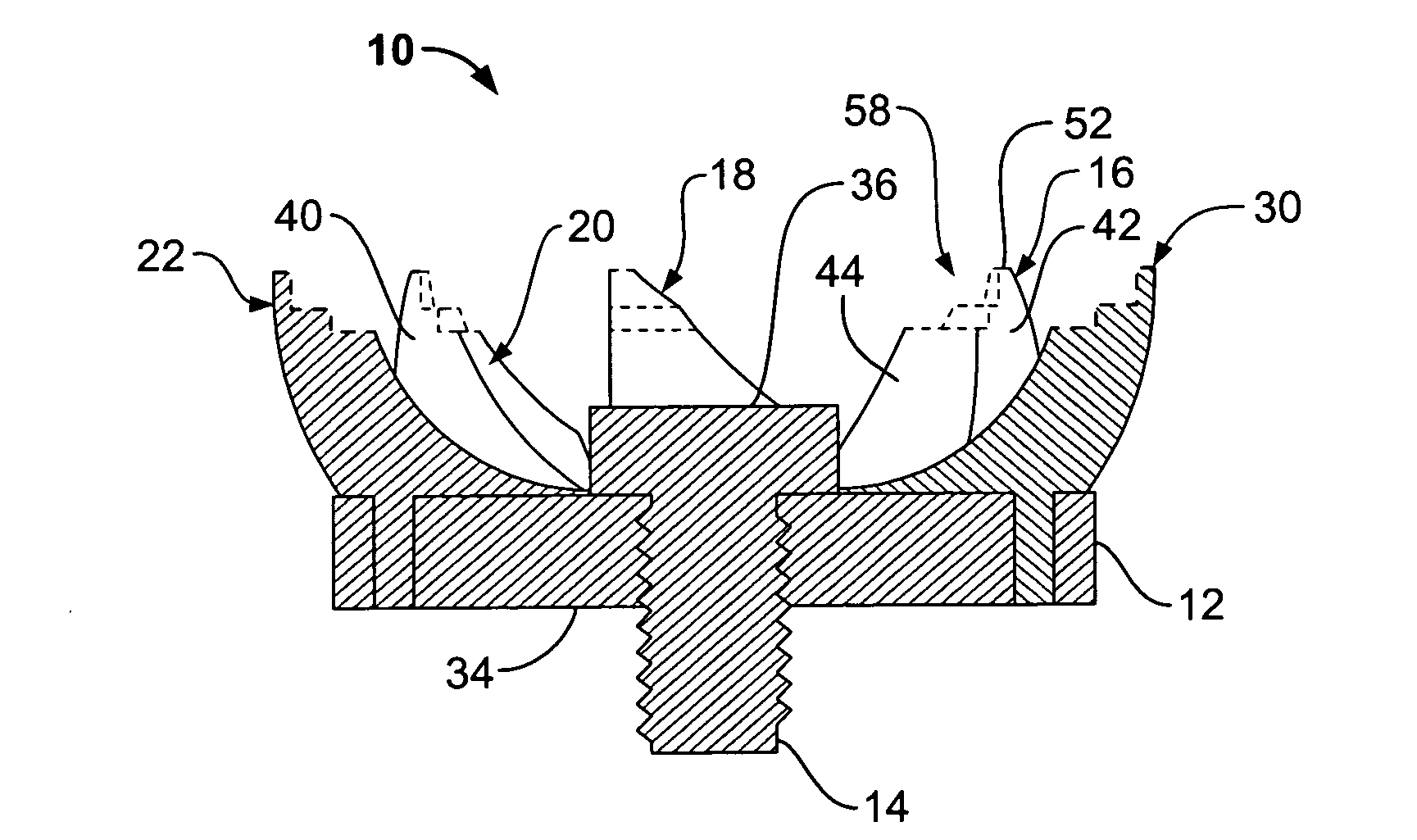

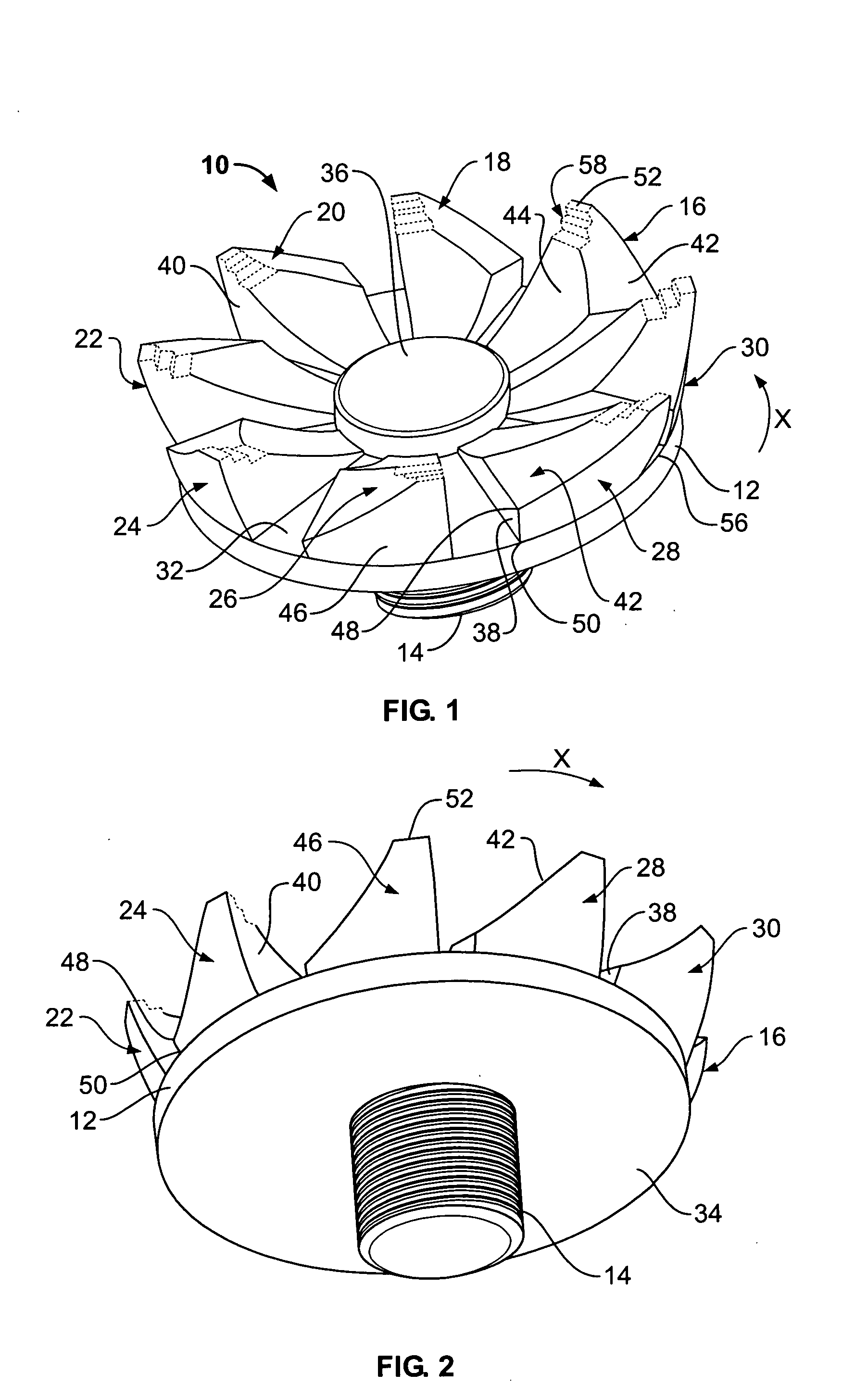

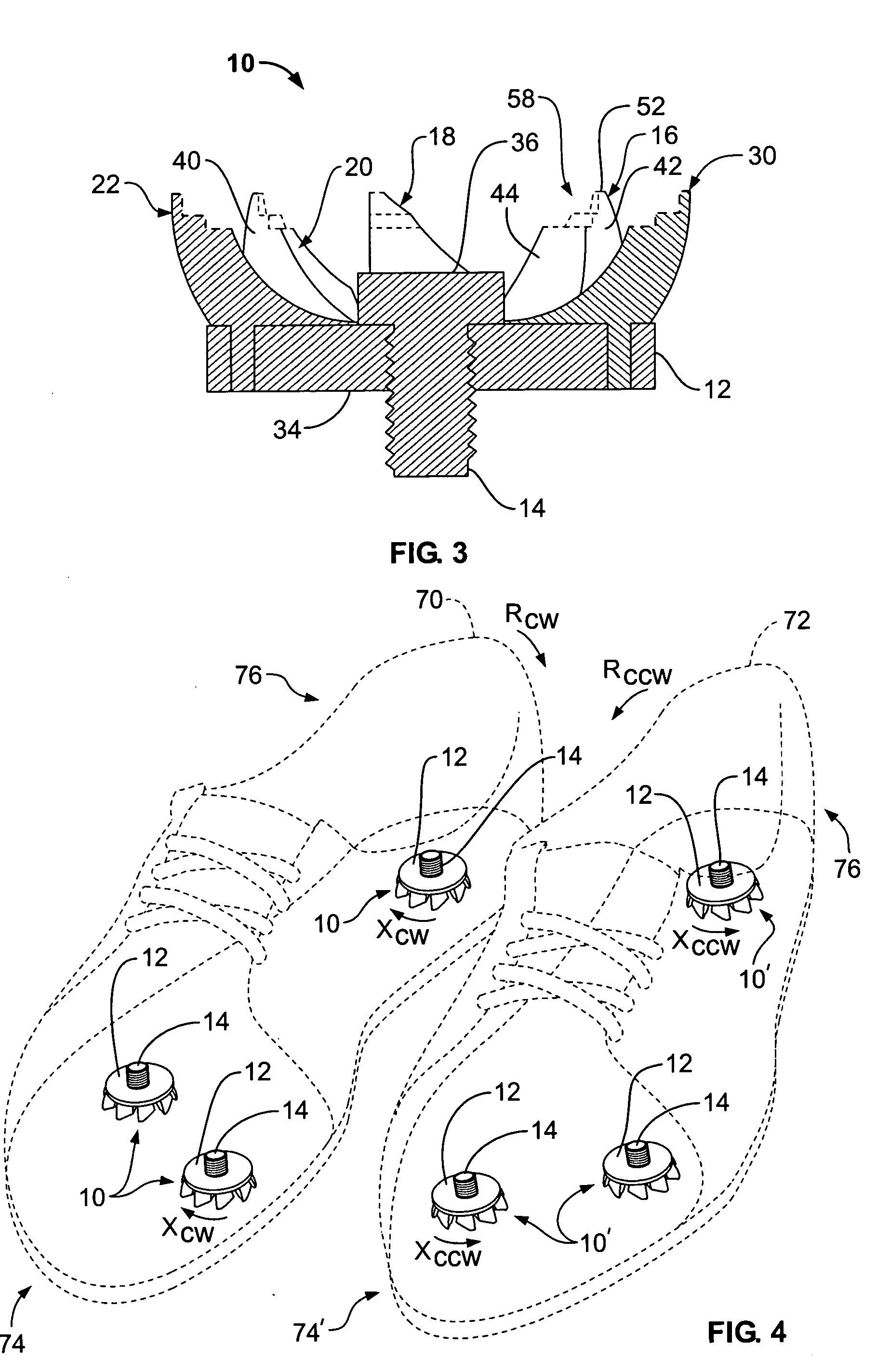

[0028] A golf cleat 10 according to one preferred embodiment of the invention is shown in FIGS. 1-3. The golf cleat 10 preferably includes a base 12, a threaded screw 14, and, in this embodiment, eight barbs 16, 18, 20, 22, 24, 26, 28, 30. The base 12 has two oppositely opposed surfaces, the ground surface 32 and the back surface 34. The threaded screw 14 is preferably attached to the back surface 34. This allows a user to removably secure the golf cleat 10 into a threaded receiving hole in the bottom sole of a shoe (not shown), for ready replacement of the cleats with any conventional golf shoe.

[0029] The eight barbs 16-30 are connected to the ground surface 32 and centered around a hub 36. Each barb 16-30 is identical and therefore it is understood that a description of one barb 16 is sufficient to describe all barbs 16-30. Barb 16, best seen in FIGS. 1 and 4, preferably has a minor surface, the rear surface 38, and four main surfaces, the perpendicular surface 40, the angular su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com