Method for designing a cryogenic air separation plant

a technology for air separation and cryogenic air, which is applied in the direction of refrigeration and liquid storage, lighting and heating equipment, solidification, etc., can solve the problems of increasing the overall cost of the plant beyond the equipment and construction costs, and the design of the cryogenic air separation plant is a complicated and thus costly endeavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

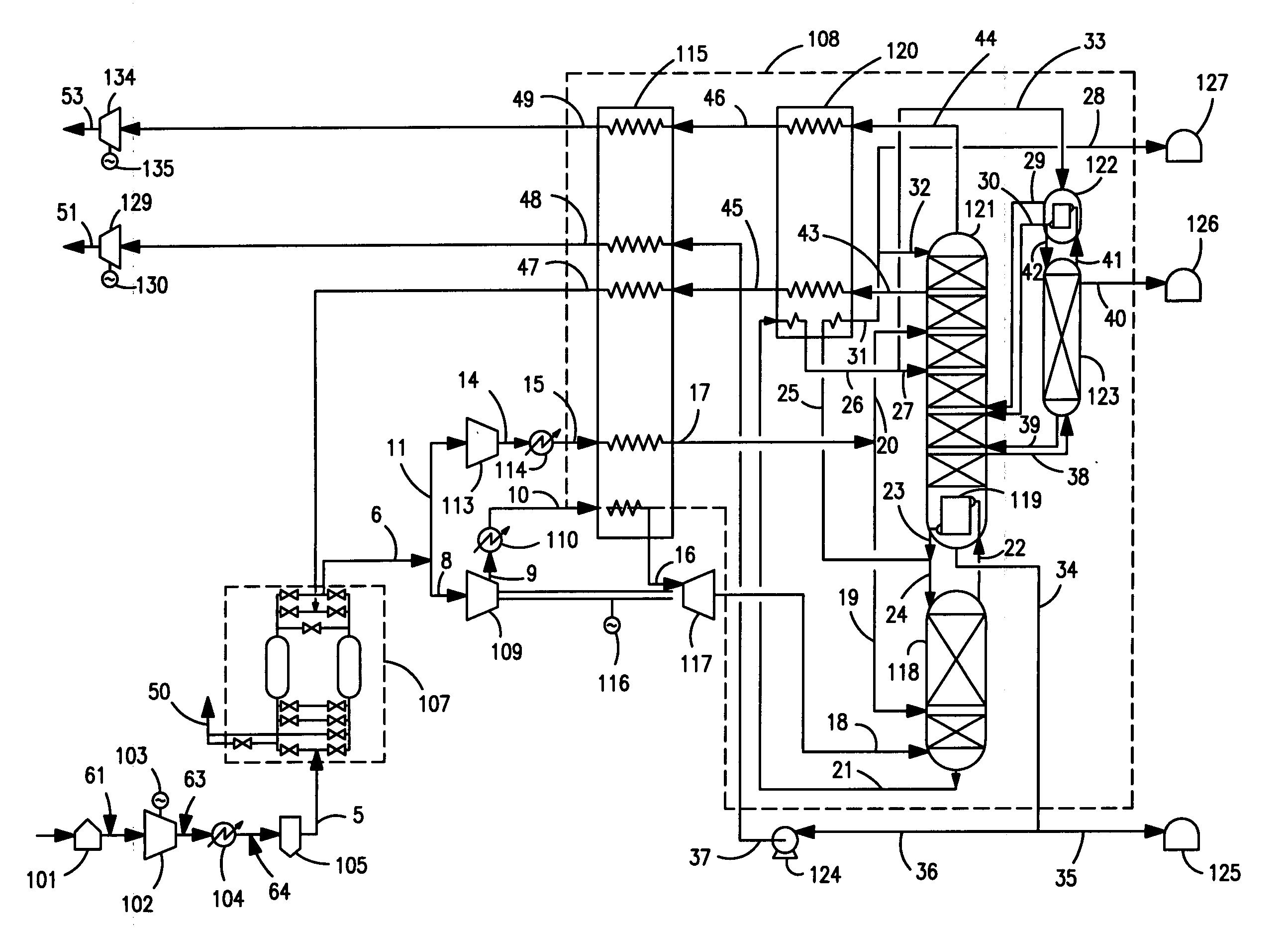

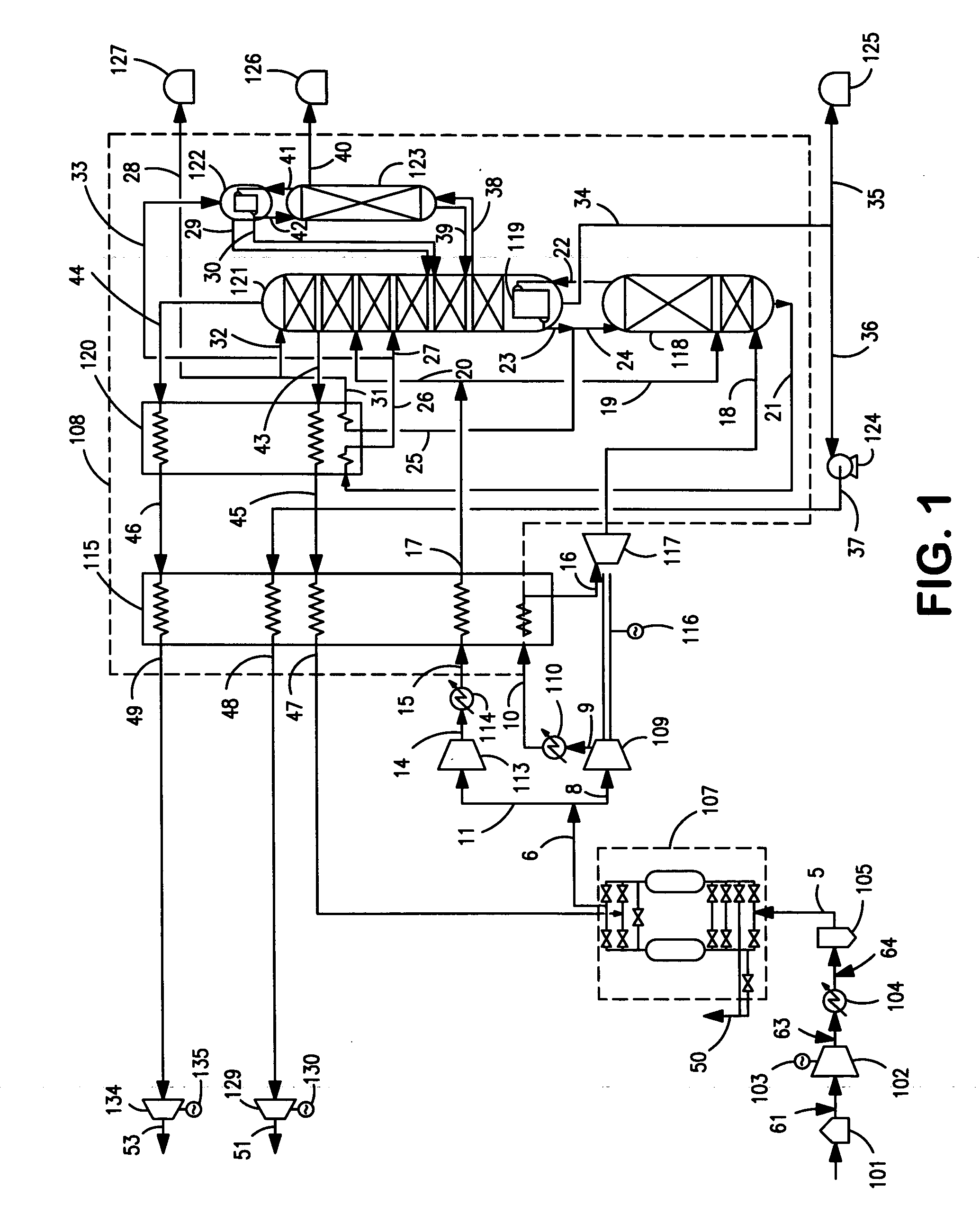

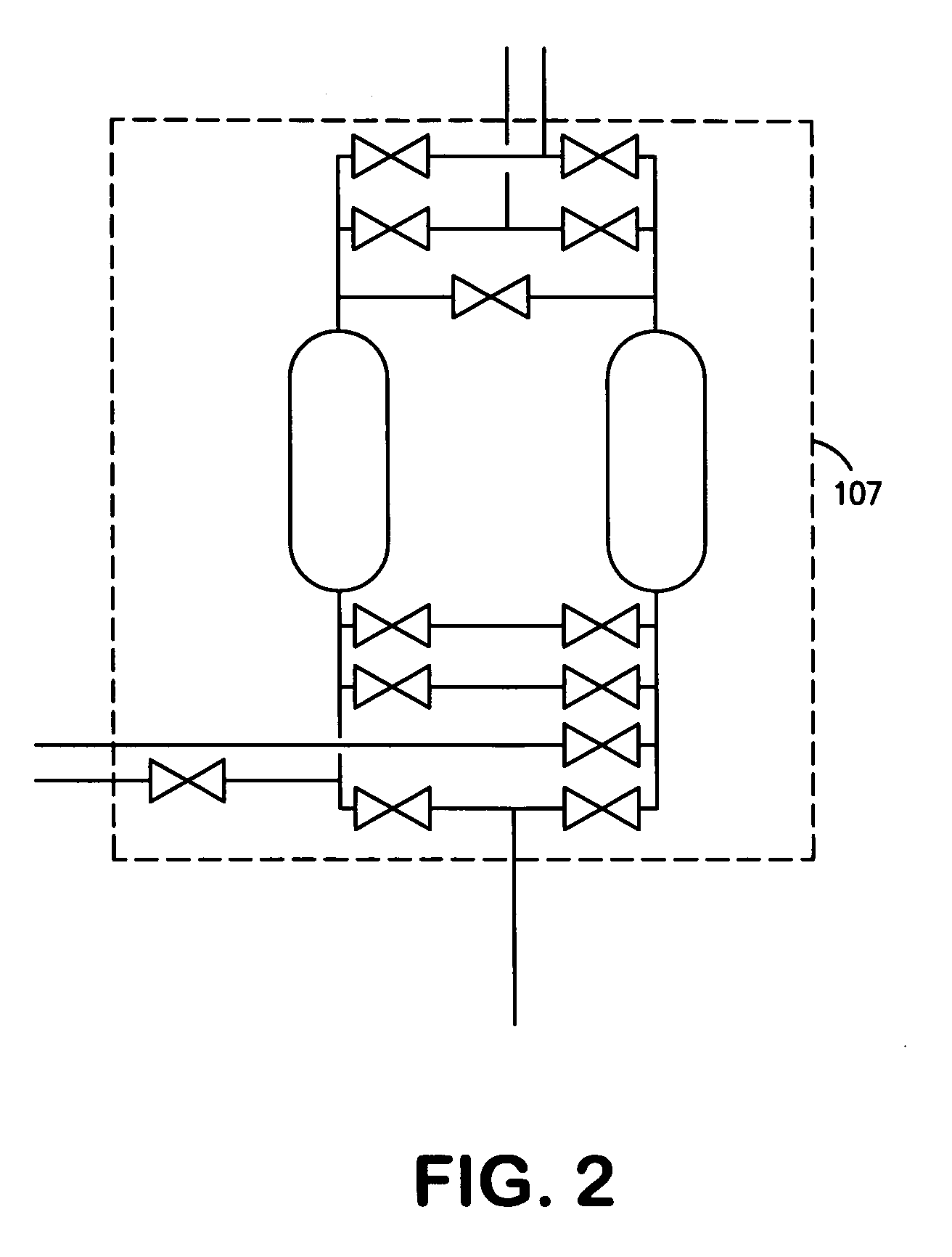

[0016] In the method of this invention cryogenic air separation plant classifications based on specific requirements such as plant size, i.e. capacity, product slate (oxygen, nitrogen, argon and / or clean dry air, etc.), product type (gas and / or liquid), product specification (purity and / or pressure) and location (back-up needs, ambient conditions, local factors etc.), are defined. The desired cryogenic air separation plant fits into one of the classifications and is designed by fitting together at least one predesigned subsystem for that classification with one or more subsystems specifically designed for that particular cryogenic air separation plant.

[0017] In the practice of this invention a base system is defined to comprise at least one, preferably two or more, predesigned subsystems that are common to meet different requirements regarding, for example, product type and purity. An auxiliary system is defined to comprise one or more subsystems that are designed specifically to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com