Patio heater with directional control

a directional control and heater technology, applied in the field of outdoor heating methods and equipment, can solve the problems of not being safe for children, not being efficient enough to be placed on the periphery of the seating area, and affecting the safety of children, so as to improve the economical use and distance and direction, extend and focus the heat, and increase the distance capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

—PREFERRED EMBODIMENT

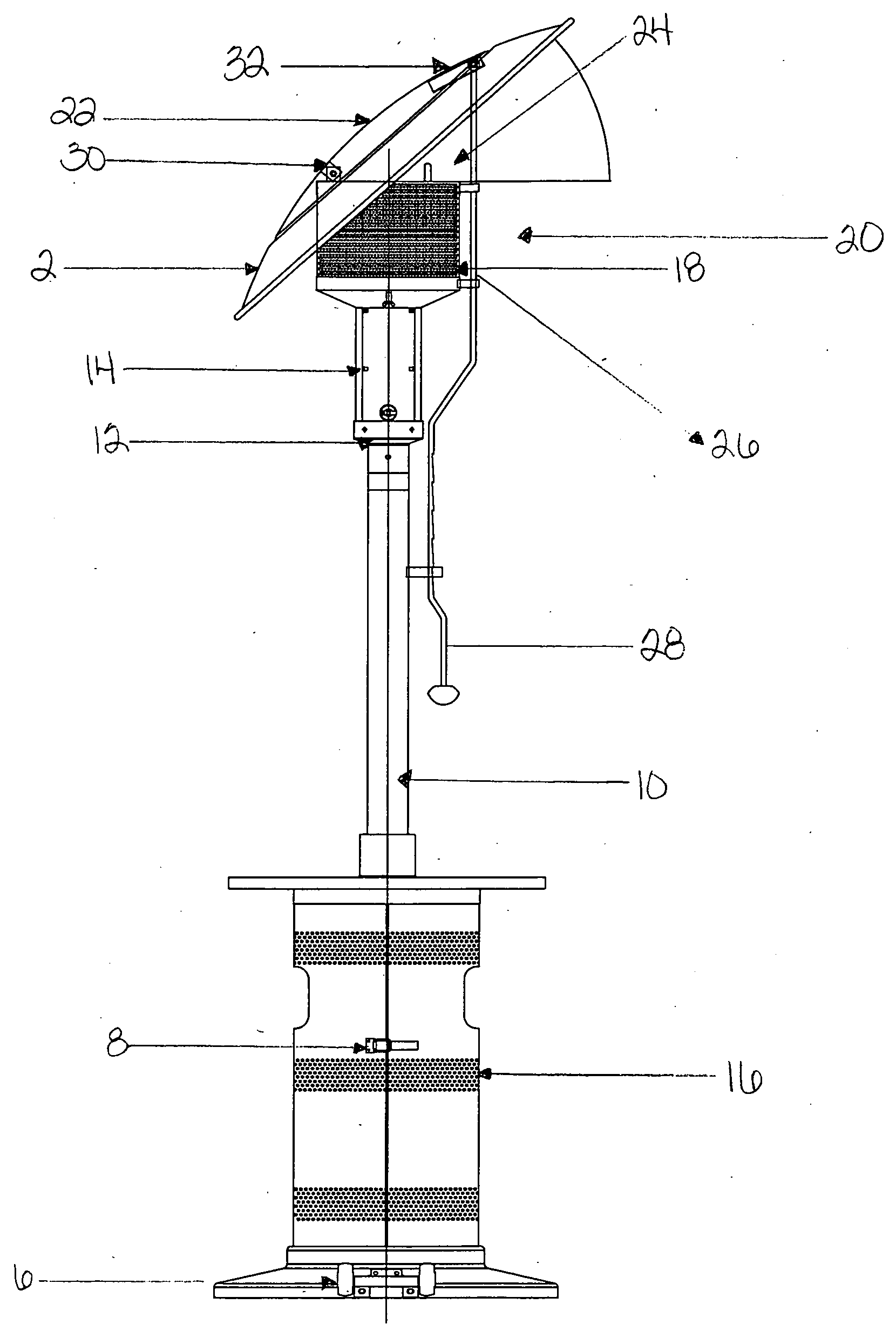

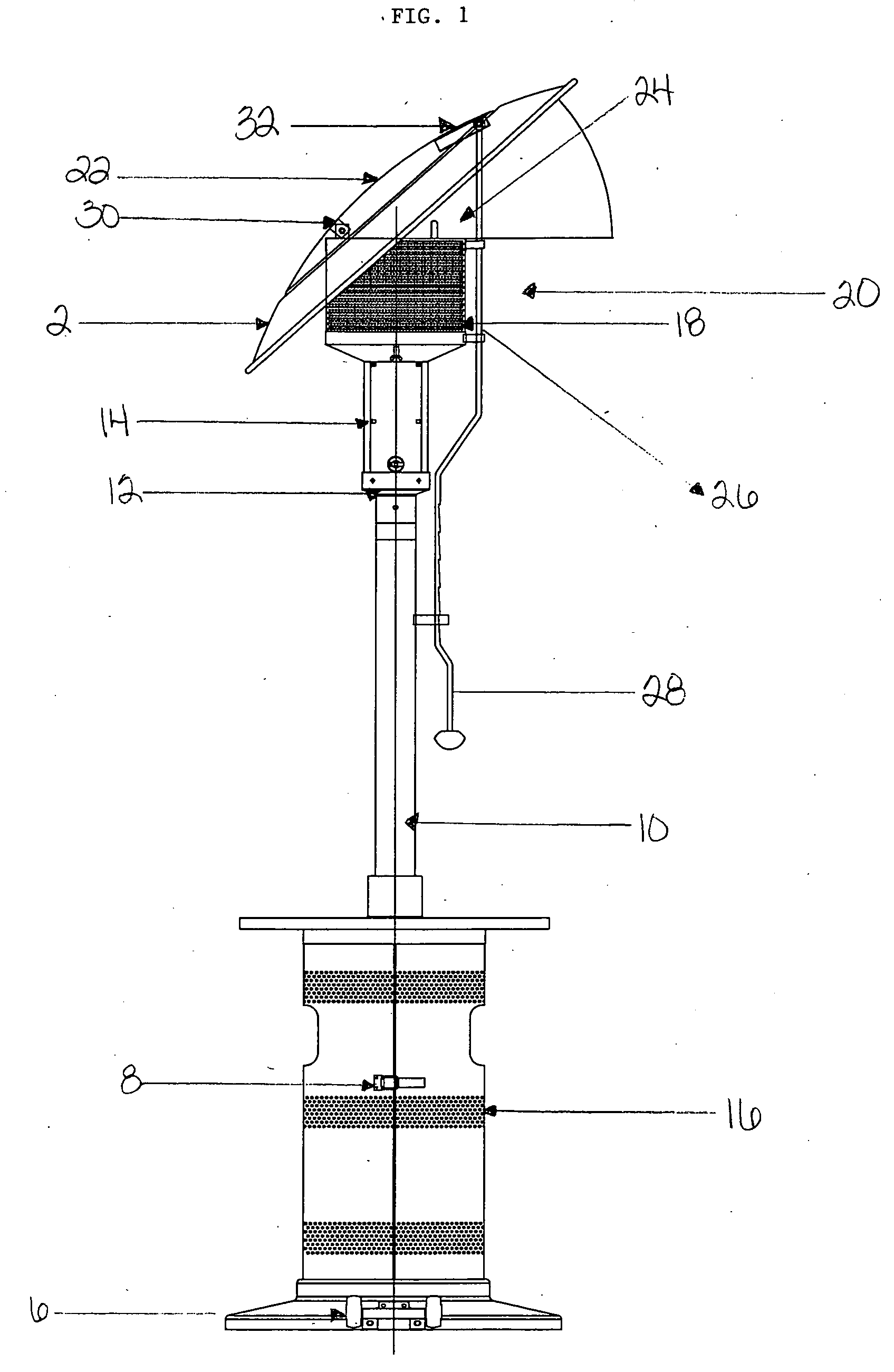

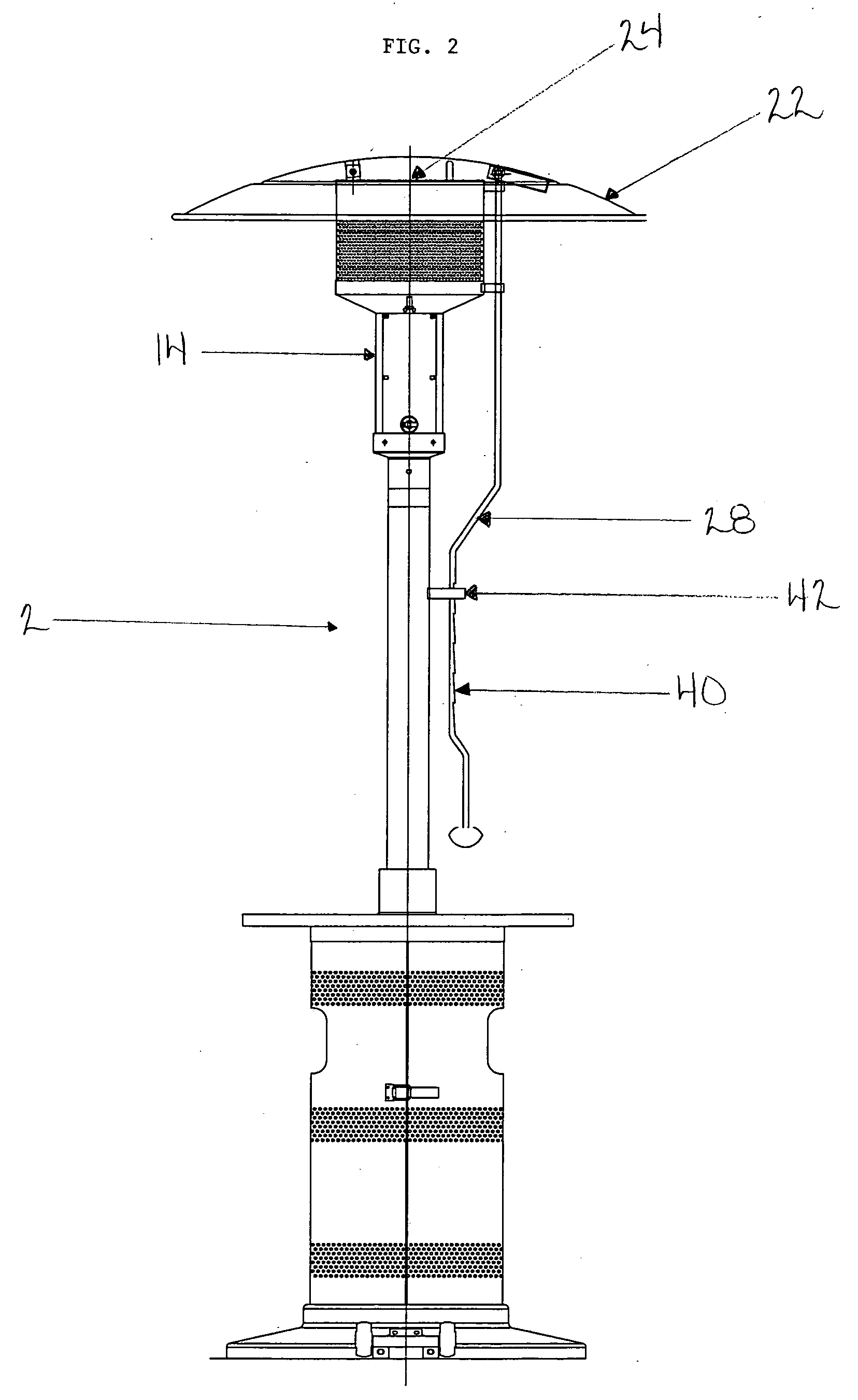

[0017] Referring now to the drawings, FIG. 1 shows a first embodiment of the patio heater 2 of the instant invention, comprising an elongated support member 10 with an upper end 12. The upper end 12 supports the heat source 14, which heat can be generated by combustion, resistance or some other means as the circumstance or need may require.

[0018] In a first embodiment, fuel such as LP gas or propane is stored in the enclosure 16 at the base of the elongated support member 10. The elongated support member 10 is preferably hollow in order to permit the fuel to safely travel from the enclosure 16 to the heat source 14, where combustion or other heat generation activity can occur. The shown embodiment also contains a clasp 8 that can be opened to access the LP gas or propane. Further, a set of wheels 6 are included for ease of movement and increased flexibility in floor-planning.

[0019] Once heat is generated in the heat source 14, it is directed upward by the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com