Low-hydrogen photovoltaic cell

a photovoltaic cell, low-hydrogen technology, applied in the direction of solid-state diffusion coating, electric/magnetic/electromagnetic heating, vacuum evaporation coating, etc., can solve the problems of unsuitable large-scale manufacturing, undesirable cigs process of chen species for industrial scale manufacturing, and undesirable second selenization process of ermer species, so as to enhance the versatility and adaptability of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention comprises systems, apparatus, and methods that provide improved means for fabricating photovoltaic material that overcome many of the disadvantages of prior art systems and methods. Though aspects of the invention are particularly applicable to the handling and treatment of photovoltaic materials, aspects of the invention may be applied to many different photovoltaic and non-photovoltaic materials.

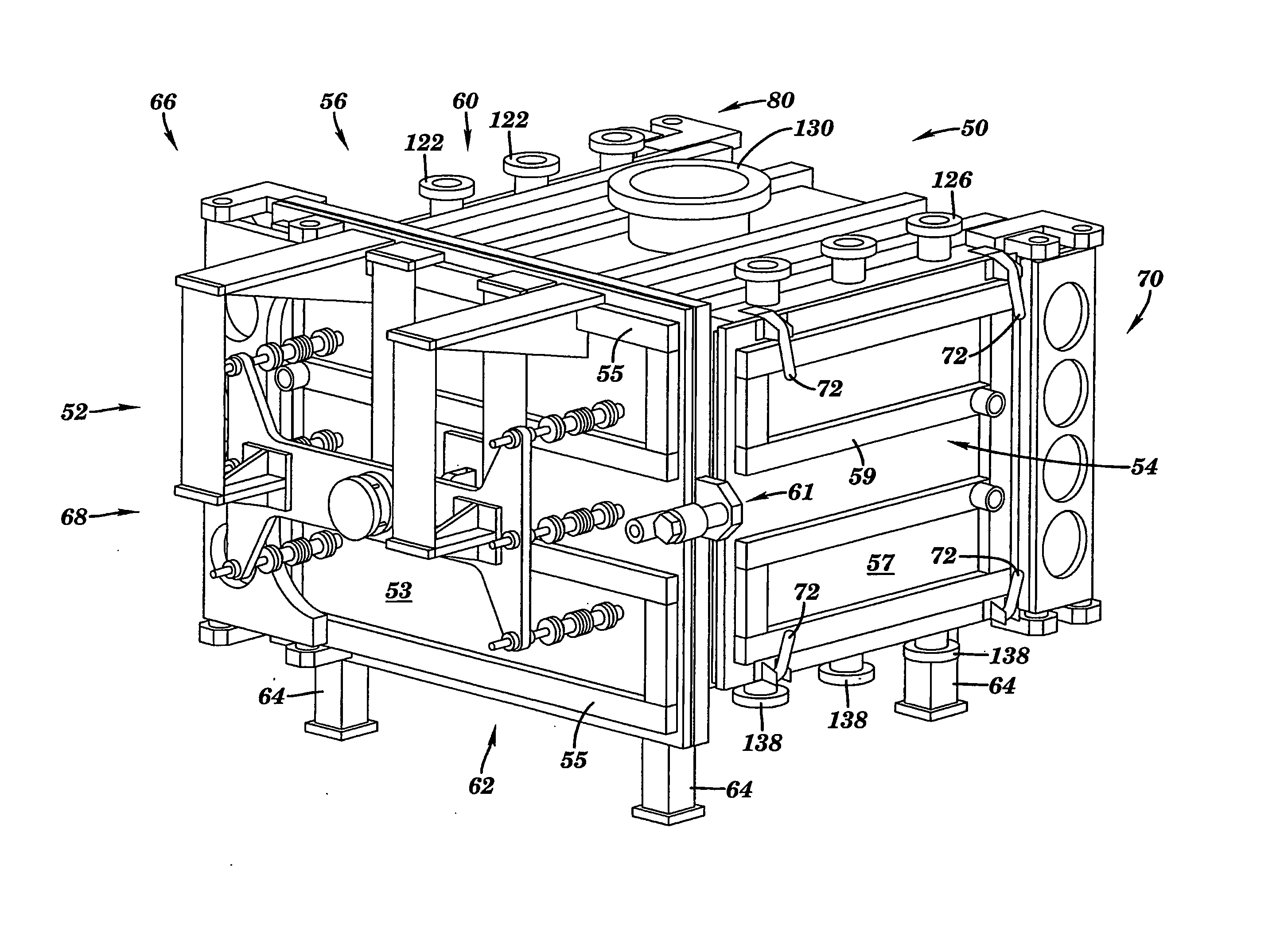

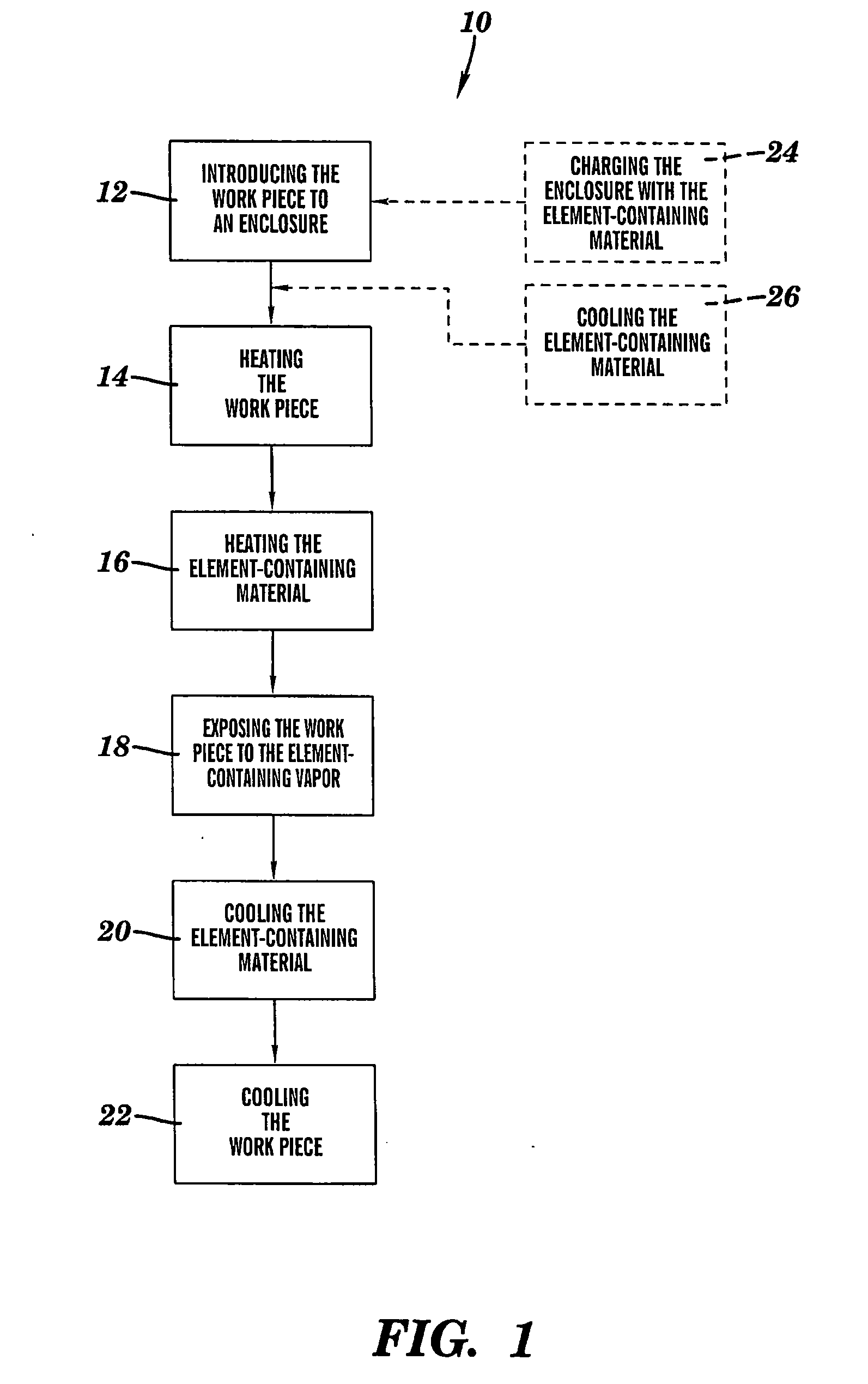

[0061]FIG. 1 is a schematic block diagram of a process 10 for treating a material according to one aspect of the invention. The material may comprise any material that is treated with a gas or vapor, for example, an element-containing vapor. In one aspect, the material comprises a photovoltaic precursor, for example, a precursor deposited on a substrate. The treatment gas may comprise any vaporous material. However, in one aspect, the treatment vapor comprises a chalcogen-containing vapor, for example, a sulfur-, selenium-, or tellurium-containing vapor; or an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com