Programmed material consolidation methods employing machine vision

a technology of machine vision and material consolidation, applied in the field of three-dimensional (3d) printing, can solve the problems of significantly slower processing time for immersion-type stereolithography systems, lack of image sensors for ensuring, and inconvenient use of 3-d printing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

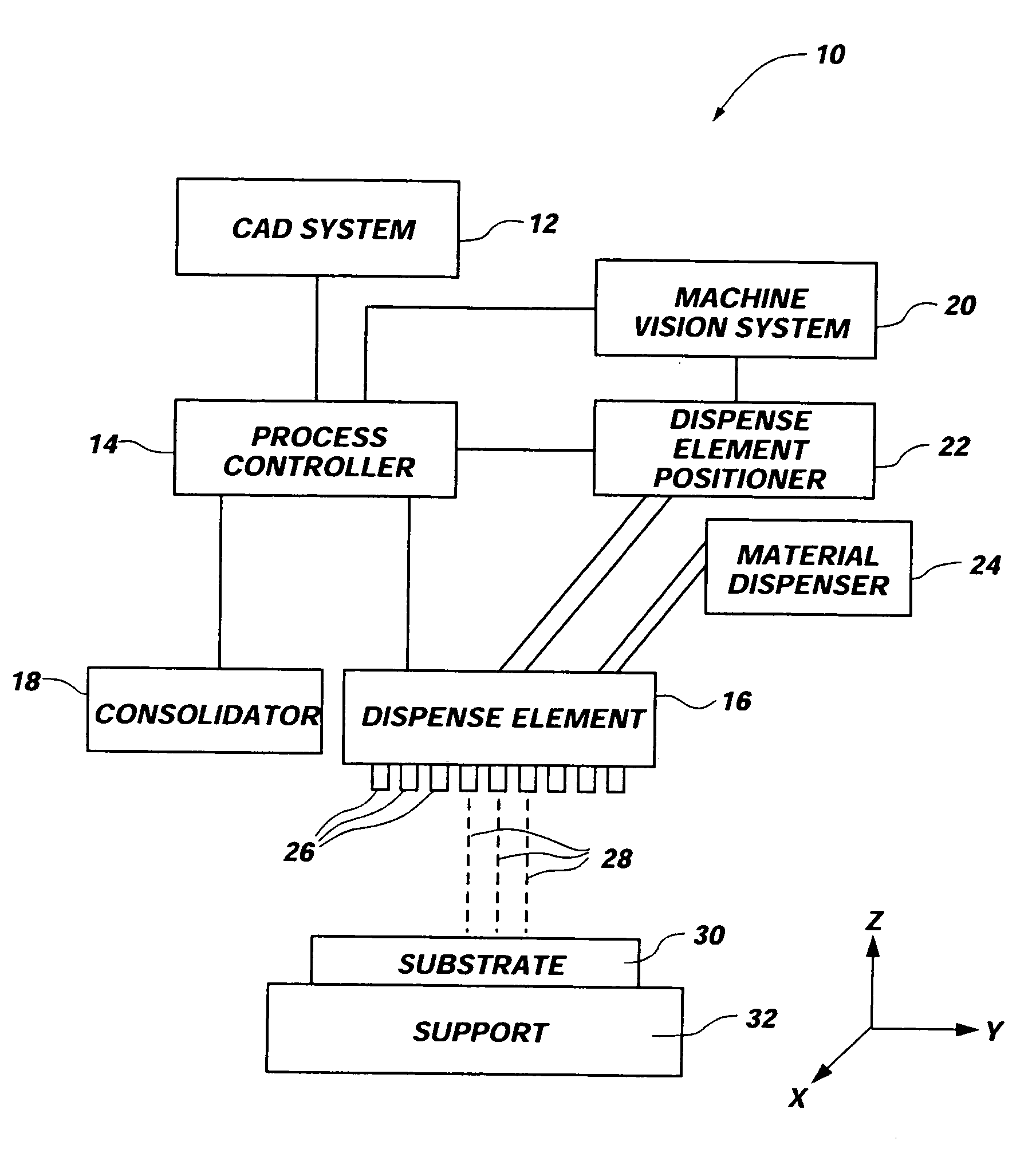

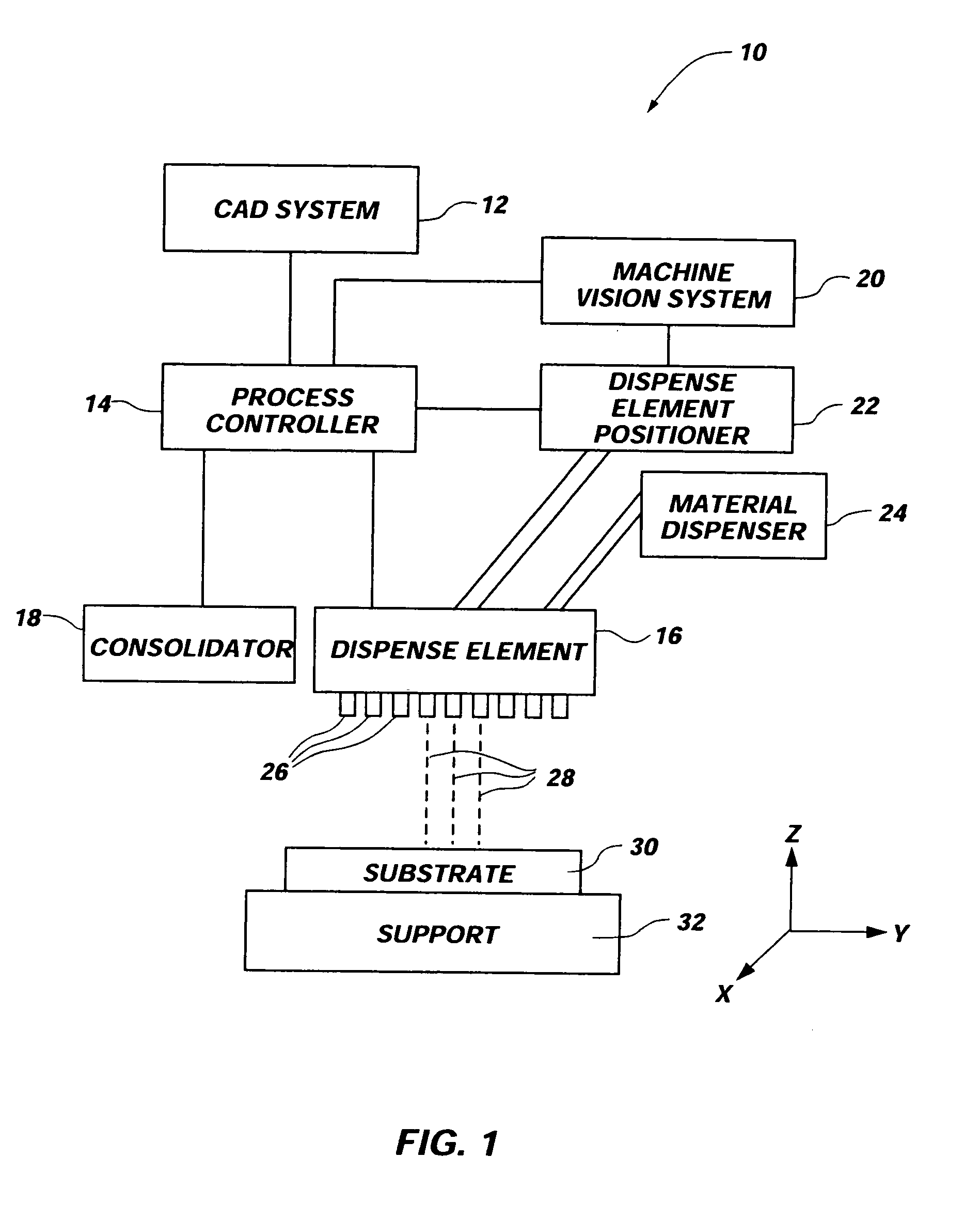

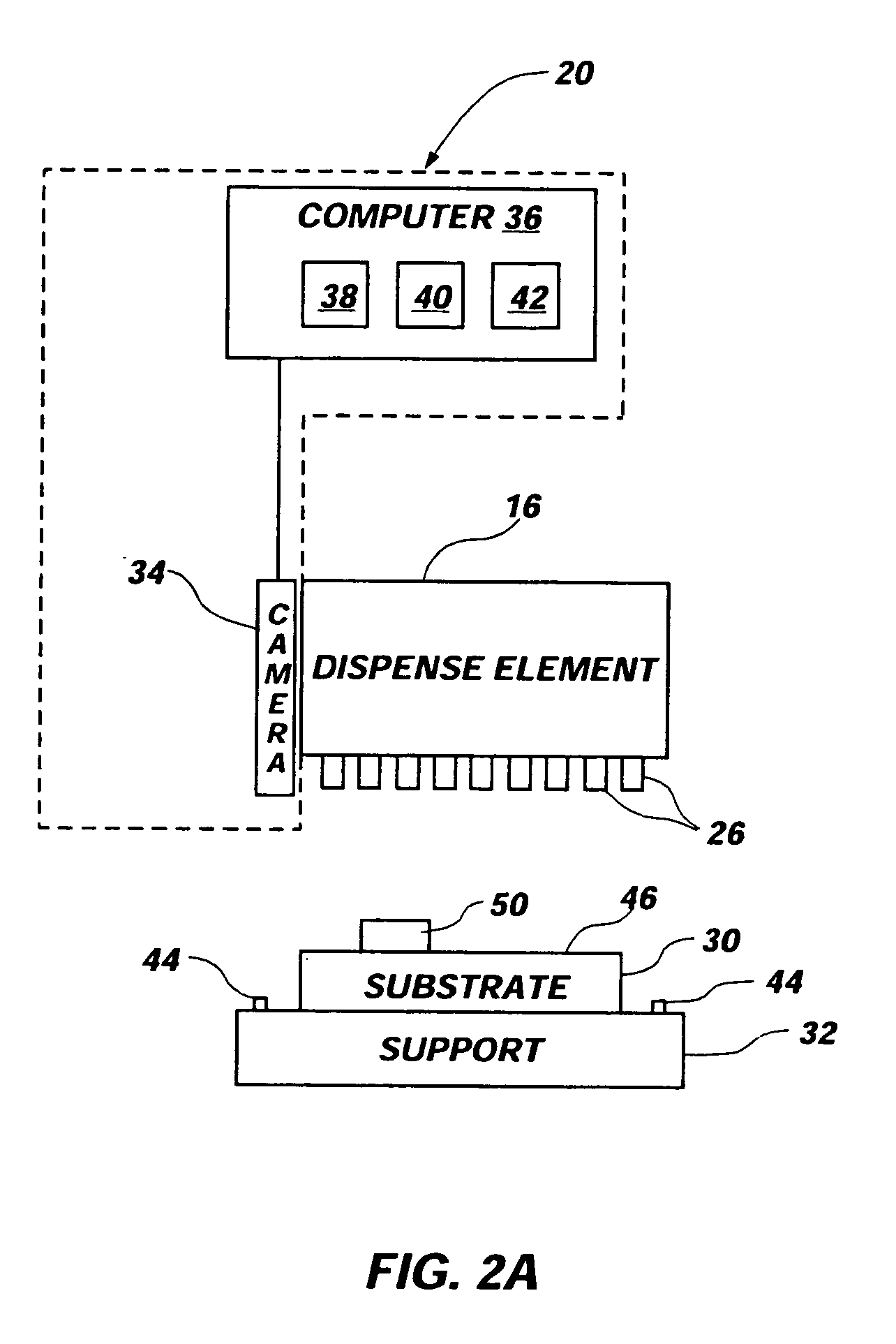

[0026]FIG. 1 illustrates a block diagram of an exemplary programmable material consolidation system 10 for 3-D printing objects that employs a machine vision system 20 enabling the accurate deposition of flowable material 28 for forming a variety of different structures. One suitable programmable material consolidation system 10 is the commercially available Eden 330® manufactured by Objet Geometries Ltd. of Rehovot, Israel, that is modified to include a machine vision system 20 in accordance with the present invention. Suitable programmable material consolidation systems and processes designed by Objet Geometries Ltd. are described in the aforementioned U.S. Pat. Nos. 6,658,314; 6,644,763; 6,569,373; and 6,259,962. Of course, teachings of the present invention are also applicable to other kinds of deposition type programmable material consolidation systems such as those commercially available from Optomec Design Company of Albuquerque, N. Mex. and described in U.S. Pat. Nos. 6,251,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| three-dimensional structures | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com