Engine cooling fan with ring reinforcement

a technology of cooling fan and reinforcement ring, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of ice formation between the reinforcement ring and the protective shroud, damage to the fan, engine damage, etc., and achieve the effect of reducing the build-up of ice therebetween

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

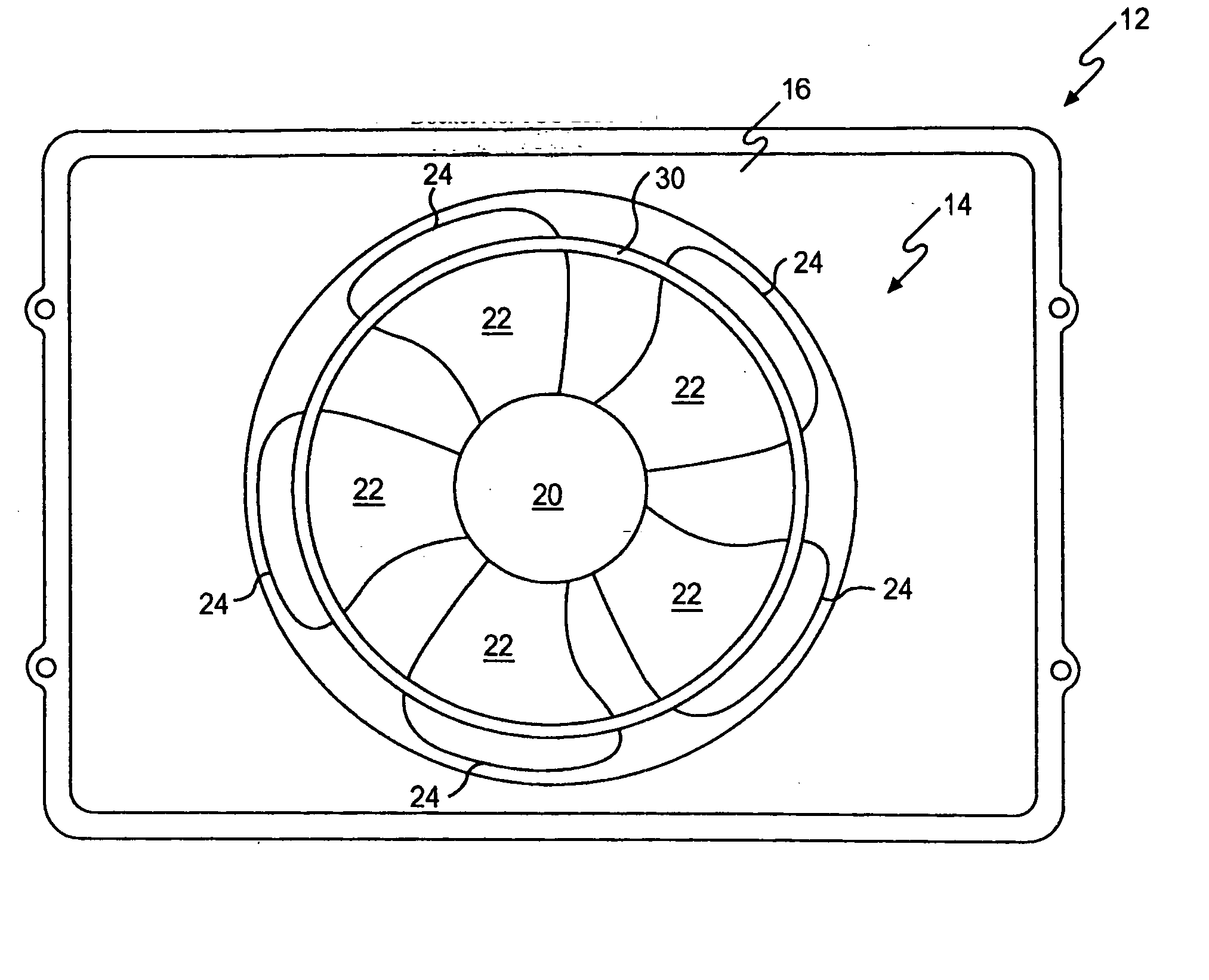

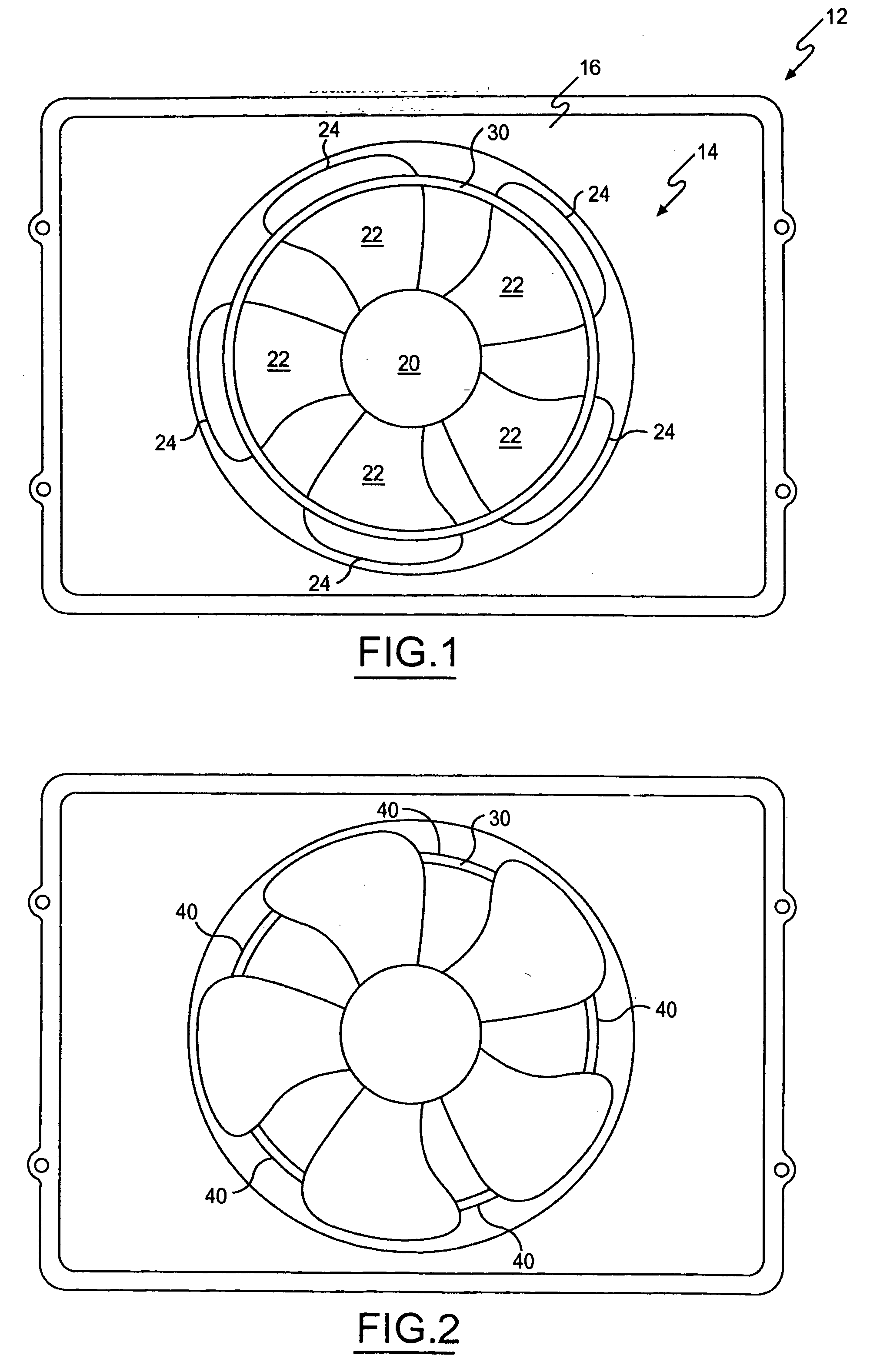

[0014] Referring to FIG. 1, a front end of an automotive vehicle is shown having a radiator 10, a fan shroud 12 and a cooling fan 14. The radiator 10 is of conventional design for cooling liquid passing through a block of an engine by way of heat exchange with air directed toward the radiator 10 while the vehicle is moving and / or with air propelled toward the radiator 10 by rotation of the fan 14. The fan 14 is driven by an engine driven serpentine belt or by an electric motor powered by the vehicle electrical system.

[0015] The fan shroud 12 includes an outer wall 16 defining a generally cylindrical space. The fan 14 is pivotally coupled to the vehicle. The fan 14 is disposed within the cylindrical space.

[0016] The fan 14 includes a central hub 20. The hub 20 is generally cylindrical. The fan 14 includes a plurality of fins or blades 22 shaped for directing air toward the radiator during rotation of the fan 14 in a driven direction. The fan 14 has at least three blades 22. The bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com