Wall panel and wall structure

a wall panel and wall technology, applied in the field of light weight panels, can solve the problems of relatively high cost of conventionally laid bricks and still quite considerable construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

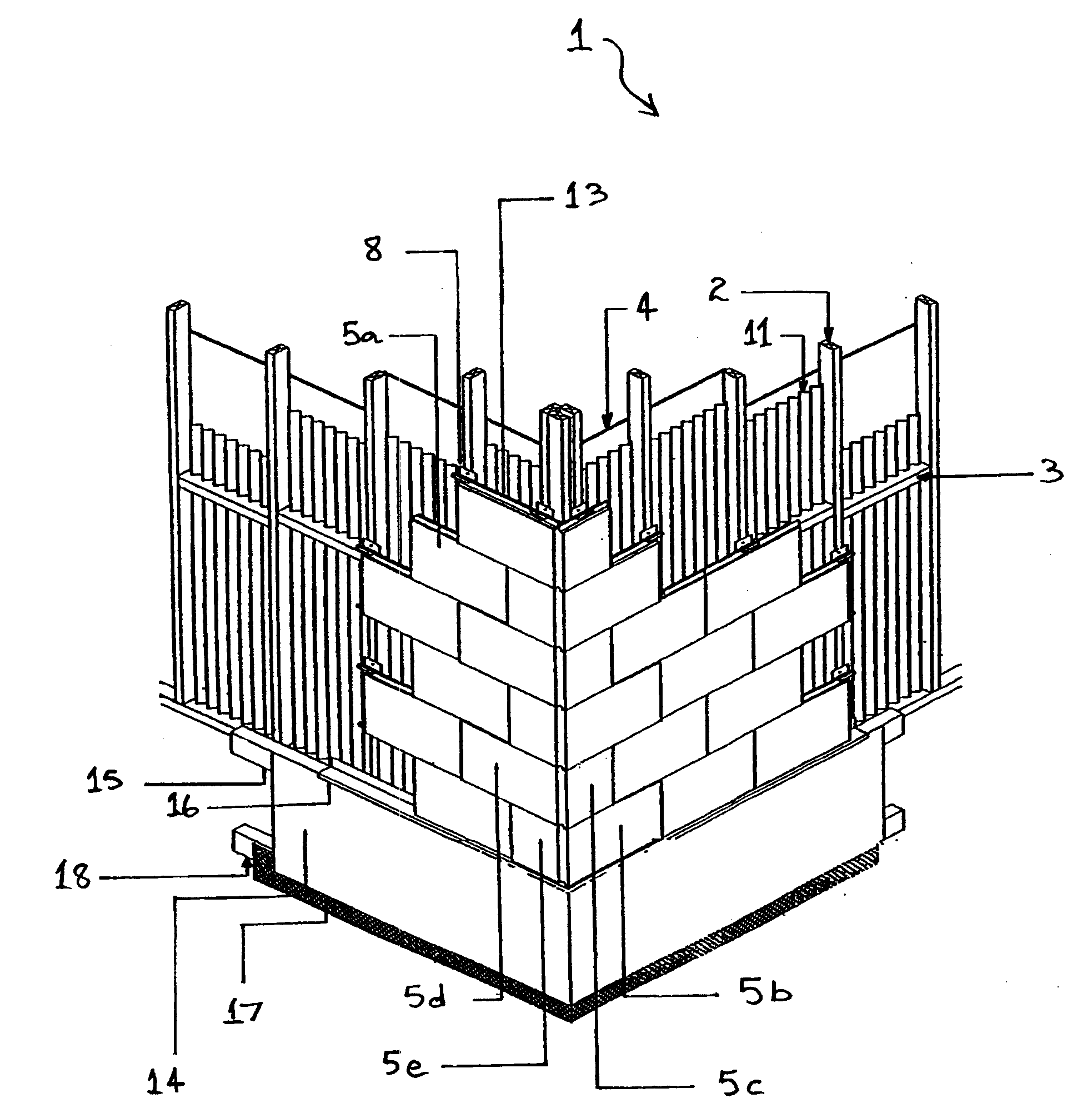

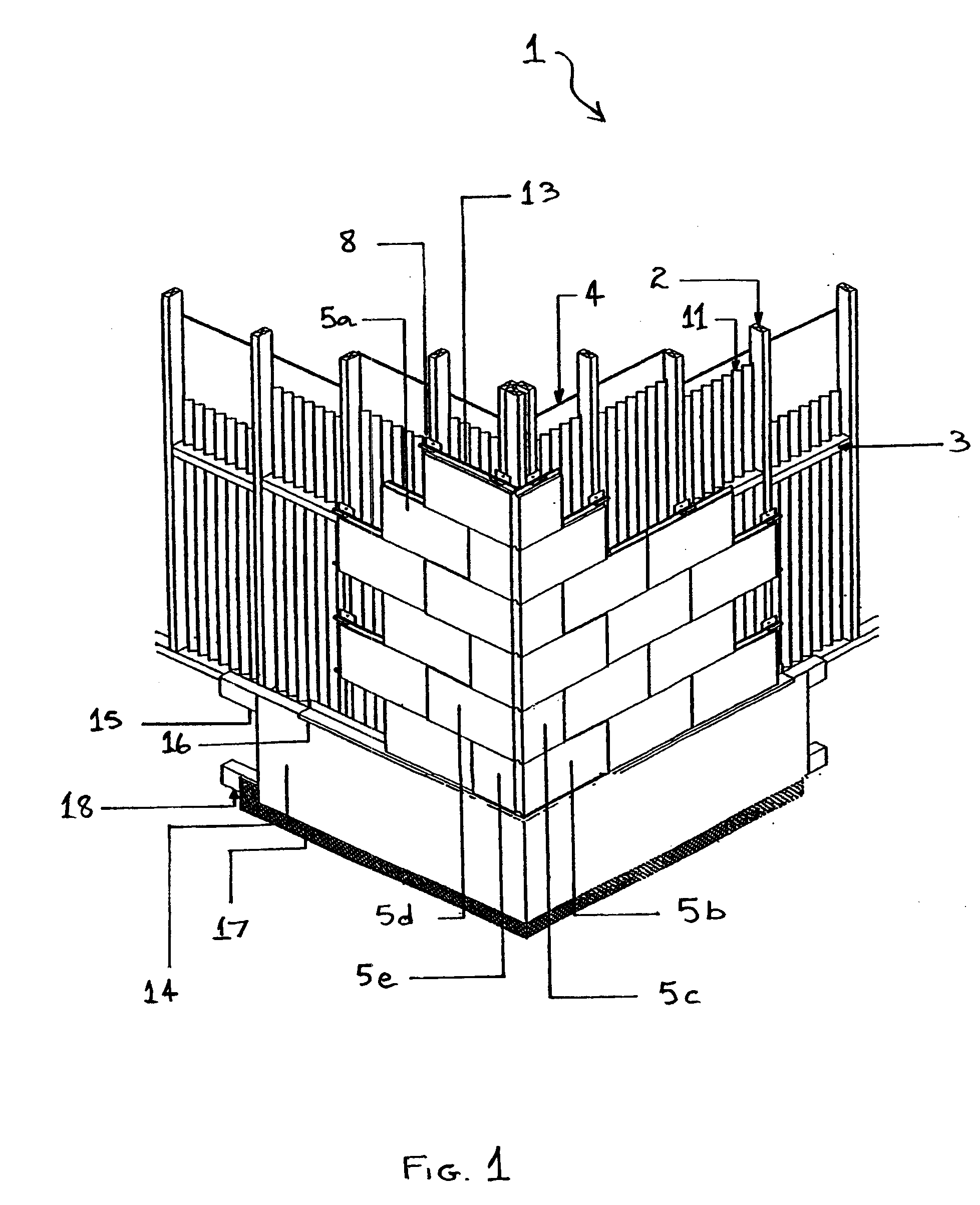

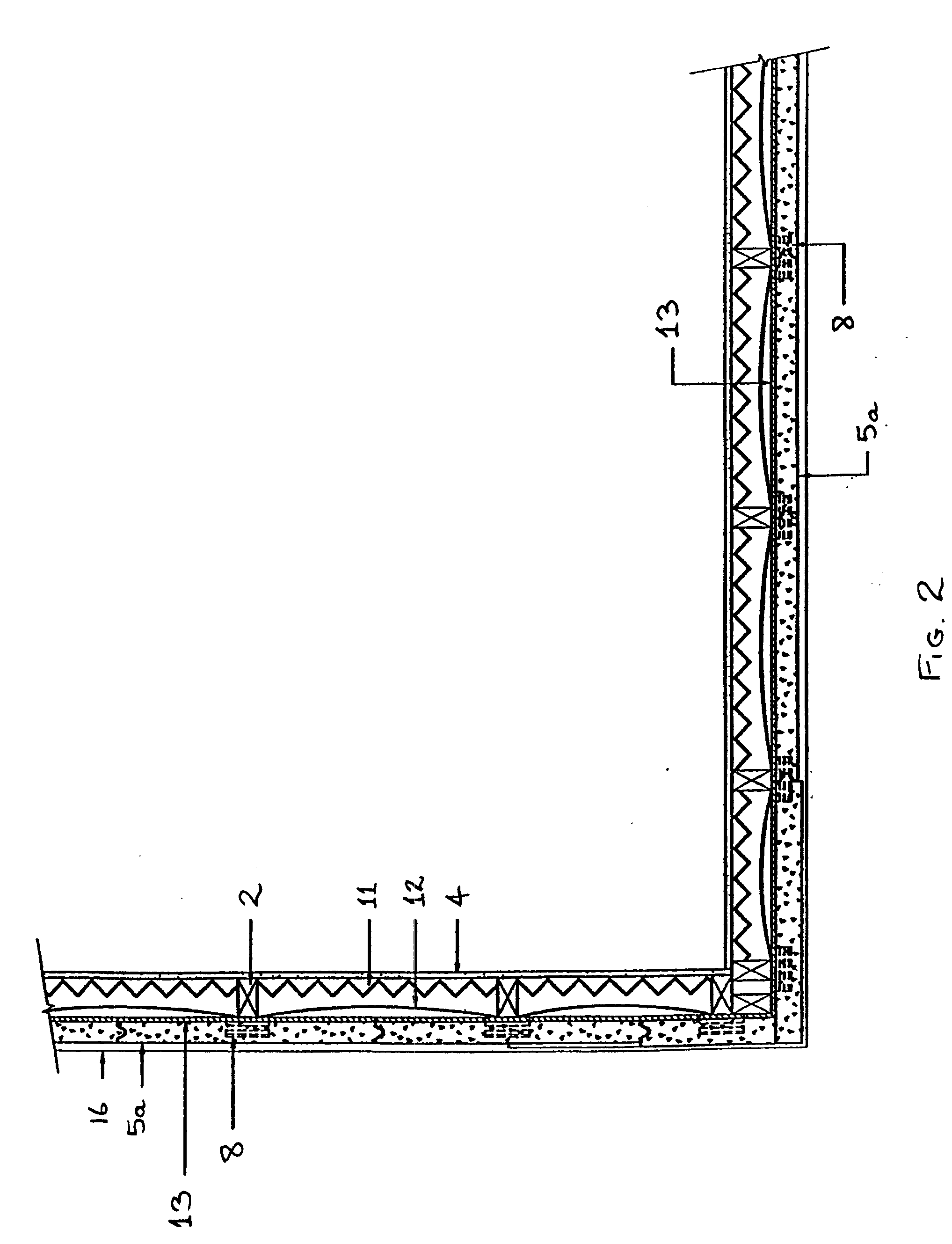

[0015]FIGS. 1 and 2 illustrate, in a simplified schematic fashion, the construction of a dwelling wall 1 having a structural frame comprising of wooden studs 2 and noggings 3. In this embodiment the studs 2 and noggings 3 are preferably 100 mm×50 mm (4×2 inches) pine, but in other embodiments may be of different size, timber or material.

[0016] The inner layer of dwelling wall 1 comprises of conventional plasterboard liner 4, which is typically about 13 mm thick, attached to the structural frame of studs 2 and noggings 3.

[0017] The outer layer of dwelling wall 1 comprises of a plurality of lightweight concrete panels 5a, 5b, 5c, 5d and 5e. Each standard panel 5a and corner panel 5b is about 600 mm×300 mm×50 mm, whilst smaller corner panel 5c is about 300 mm×300 mm×50 mm, however this size is not critical. What is of substantial economic importance is that each panel is of a size equivalent in wall surface area to many bricks and can be much more quickly and conventionally lifted, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com