Fireproof polystyrene heat preservation plate and preparing method thereof

A technology of polystyrene and polystyrene particles, applied in flat products, other household appliances, applications, etc., can solve the problems of toxic smoke, high energy consumption, non-compliance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

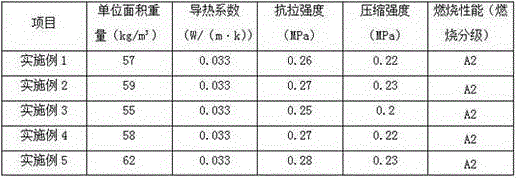

Examples

Embodiment 1

[0025] (1) Weigh 35 parts of urea-formaldehyde resin, 15 parts of alkyd resin, 40 parts of aluminum hydroxide, 4 parts of ammonium polyphosphate, 5 parts of pentaerythritol, 0.4 parts of silane coupling agent, 0.2 parts of defoamer, 0.4 parts of iron oxide red , Mixing and stirring to prepare a liquid flame retardant, stirring conditions: stirring at a speed of 2000 revolutions per minute at room temperature for 3 hours; wherein iron oxide red is a pigment, and using iron oxide red as a pigment is a preferred method of this embodiment. Iron oxide black or other colored substances can also be used as pigments according to actual needs;

[0026] (2) Put the expandable polystyrene master batch particles into a pre-expansion machine for pre-expansion, and mature for 8-12 hours to obtain pre-expanded polystyrene beads;

[0027] (3) The above-mentioned prefabricated flame retardant and the pre-expanded polystyrene beads are mixed uniformly in a weight ratio of 3:1, so that the liquid fla...

Embodiment 2

[0030] (1) Weigh 30 parts urea-formaldehyde resin, 20 parts alkyd resin, 40 parts aluminum hydroxide, 4 parts ammonium polyphosphate, 5 parts pentaerythritol, 0.3 parts silane coupling agent, 0.3 parts defoamer, 0.4 parts iron oxide red , Mix and stir to prepare a liquid flame retardant, stirring conditions: stirring at a speed of 2000 revolutions per minute at room temperature for 3 hours;

[0031] (2) Put the expandable polystyrene master batch particles into a pre-expansion machine for pre-expansion, and mature for 8-12 hours to obtain pre-expanded polystyrene beads;

[0032] (3) The above-mentioned prefabricated flame retardant and the pre-expanded polystyrene beads are mixed uniformly in a weight ratio of 3:1, so that the liquid flame retardant is evenly wrapped on the surface of the pre-expanded polystyrene beads. And use fluidized bed drying equipment to dry for five to ten minutes, set the temperature at 70℃~90℃;

[0033] (4) Put the wrapped beads into the plastic sheet form...

Embodiment 3

[0035] (1) Weigh 40 parts of urea-formaldehyde resin, 10 parts of alkyd resin, 42 parts of aluminum hydroxide, 3 parts of ammonium polyphosphate, 4 parts of pentaerythritol, 0.4 parts of titanate coupling agent, 0.3 parts of antifoaming agent, 0.3 parts of oxidation Iron black, mixed and stirred to prepare a liquid flame retardant, stirring conditions: stirring at a speed of 2000 revolutions per minute at room temperature for 3 hours;

[0036] (2) Put the expandable polystyrene master batch particles into a pre-expanding machine for pre-expansion, and mature for 8-12 hours to obtain pre-expanded polystyrene beads;

[0037] (3) The above-mentioned prefabricated flame retardant and the pre-expanded polystyrene beads are mixed uniformly in a weight ratio of 3:1, so that the liquid flame retardant is evenly wrapped on the surface of the pre-expanded polystyrene beads. And use fluidized bed drying equipment to dry for five to ten minutes, set the temperature at 70℃~90℃;

[0038] (4) Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com