Hydroelectric power plant and method of generating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description, the use of “a,”“an,” or “the” can refer to the plural. All examples given are for clarification only, and are not intended to limit the scope of the invention.

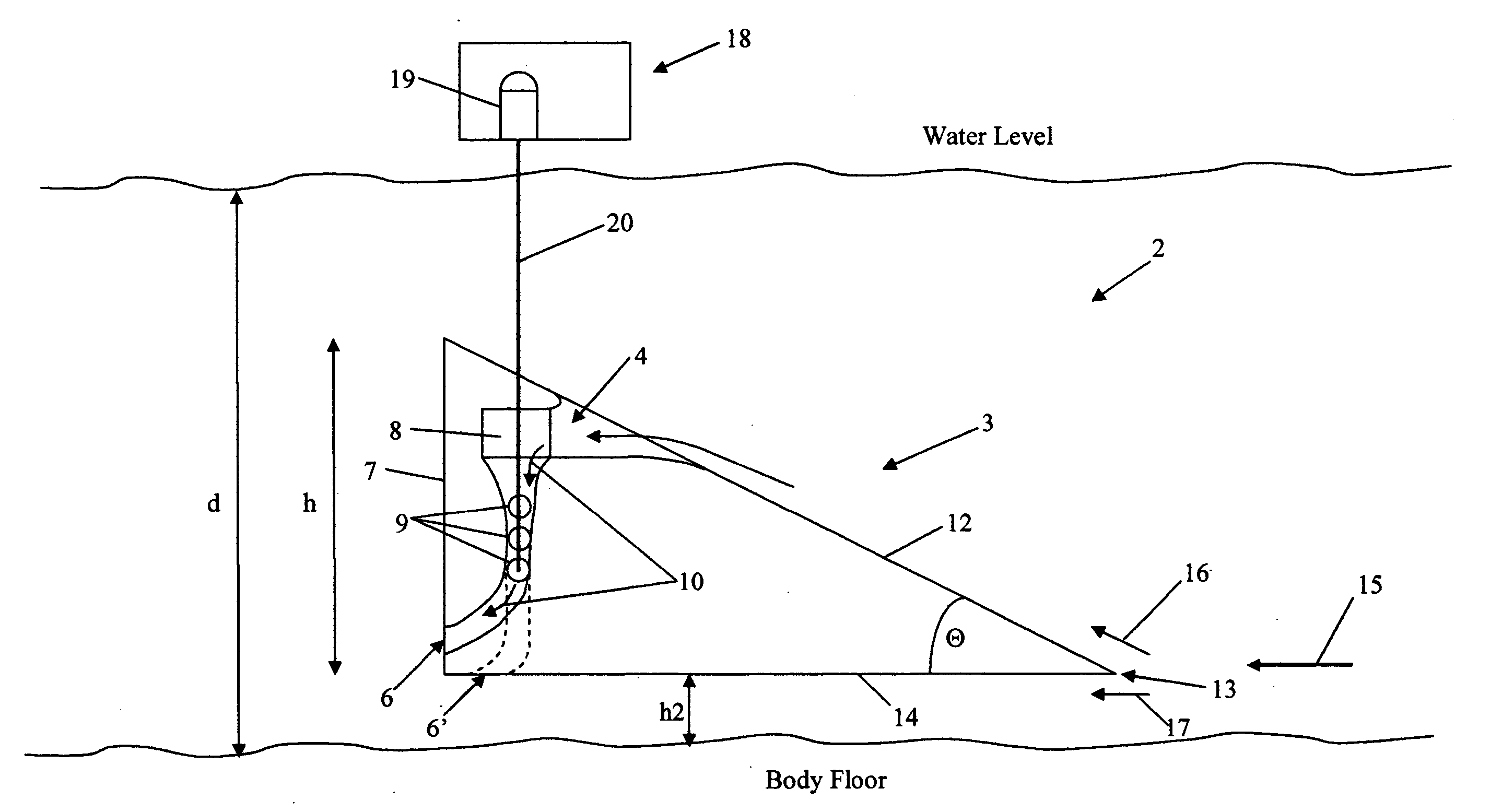

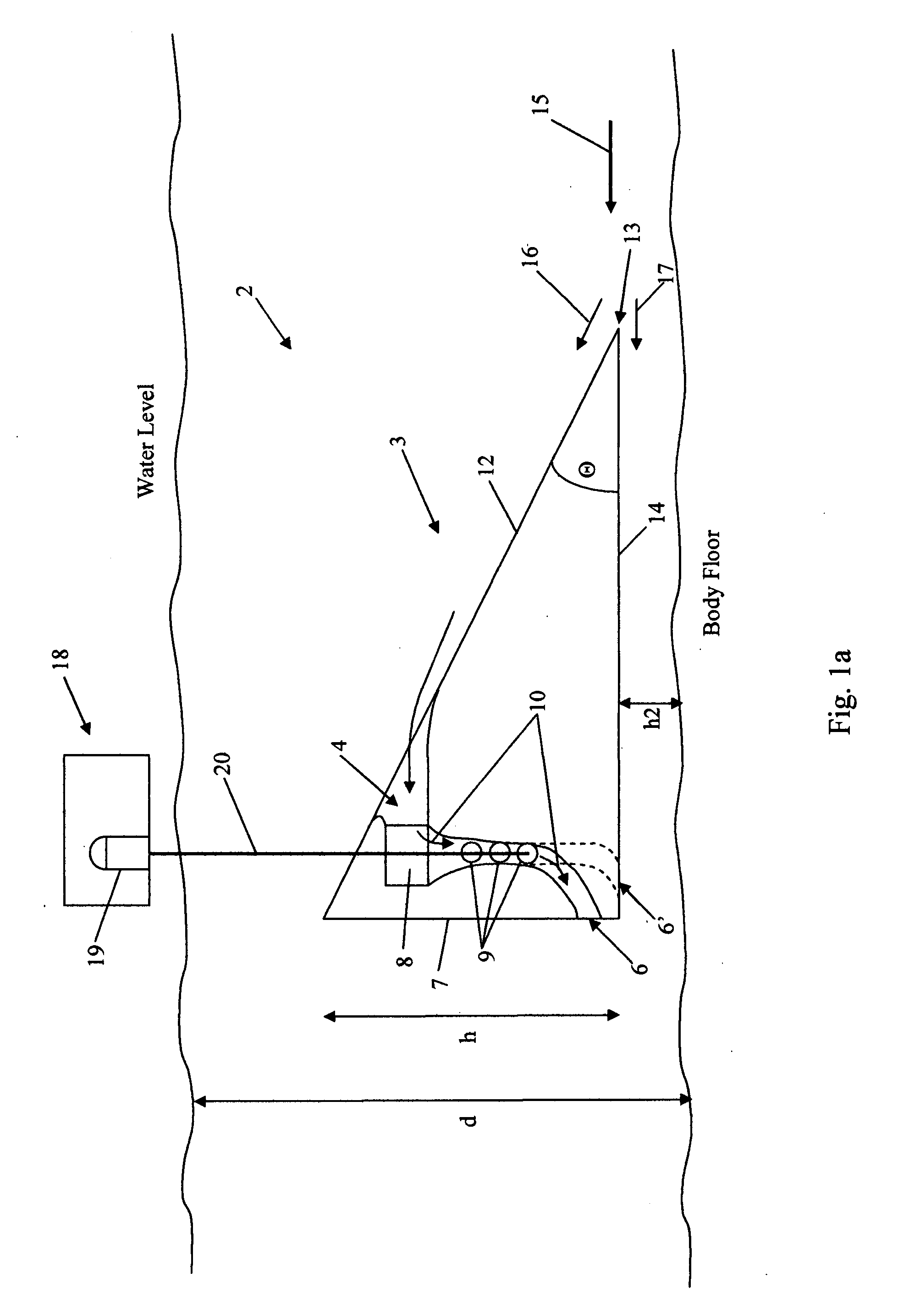

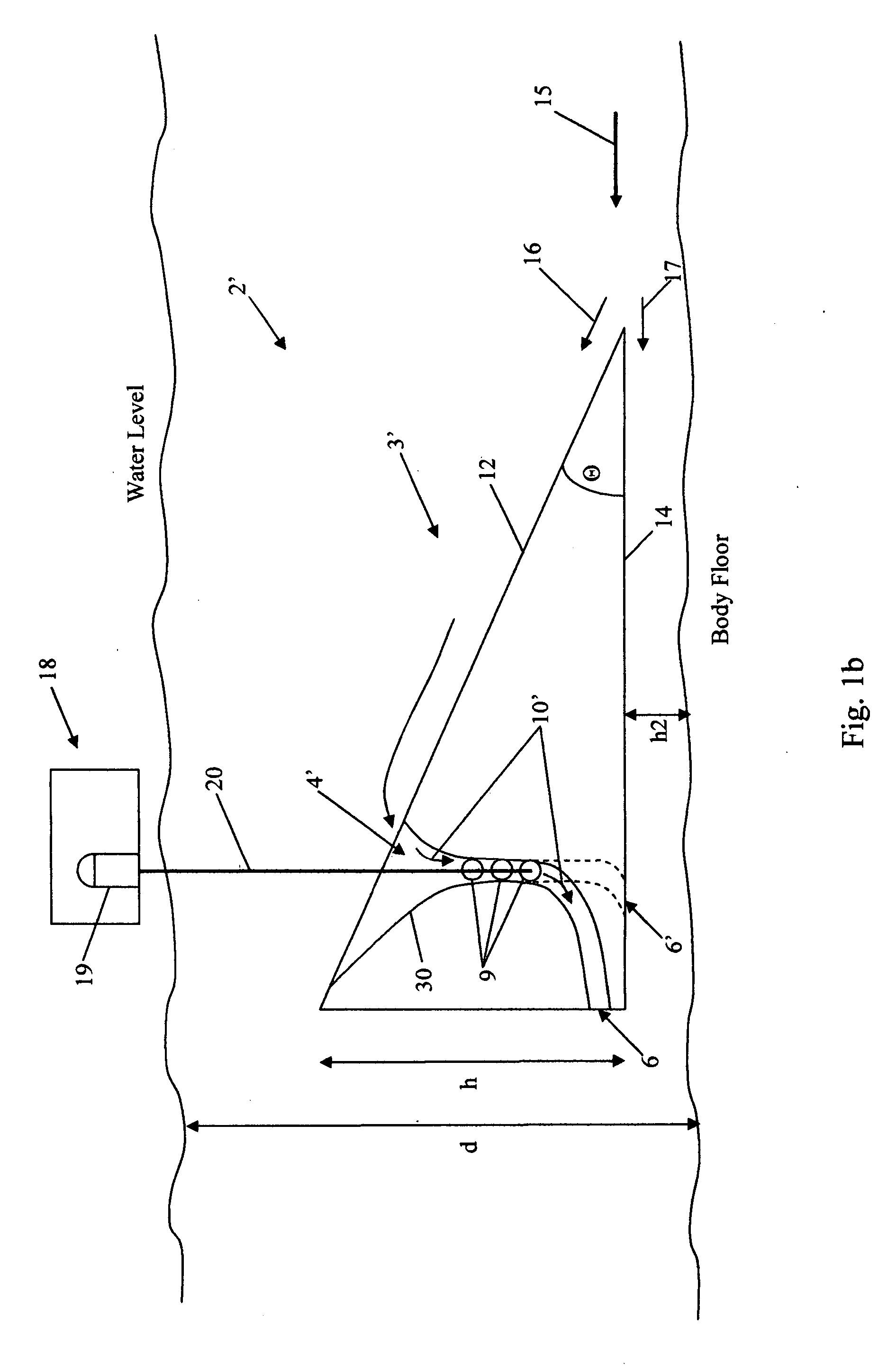

[0030] Referring now to FIG. 1a, a power plant 2 comprises a wedge 3 connected to a generating station 18 via a shaft 20. The generating station 18 includes at least one electrical generator 19, such as a generator that converts rotational energy to electricity, as known in the art. The wedge 3 is located within a body of water having a Body Floor and a Water Level, and comprises an upper surface 12 and a lower surface 14, the surfaces 12, 14 angled with respect to each other by angle Θ. The body of water has a current having a fluid flow 15. The angle Θ may be at least approximately 15°, preferably ranges from approximately 30 to 60°, and more preferably ranges from approximately 40 to 50°. The upper surface 12 may be adjustable with respect to the lower surface 14 so that the angle Θ can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com