High-temperature pipeline

a pipeline and high-temperature technology, applied in the direction of collector thermal insulation, machines/engines, light and heating apparatus, etc., can solve the problems of destroying land, fossil fuel resource dwindling, and the true cost of fossil fuel based electrical generation is only now being understood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

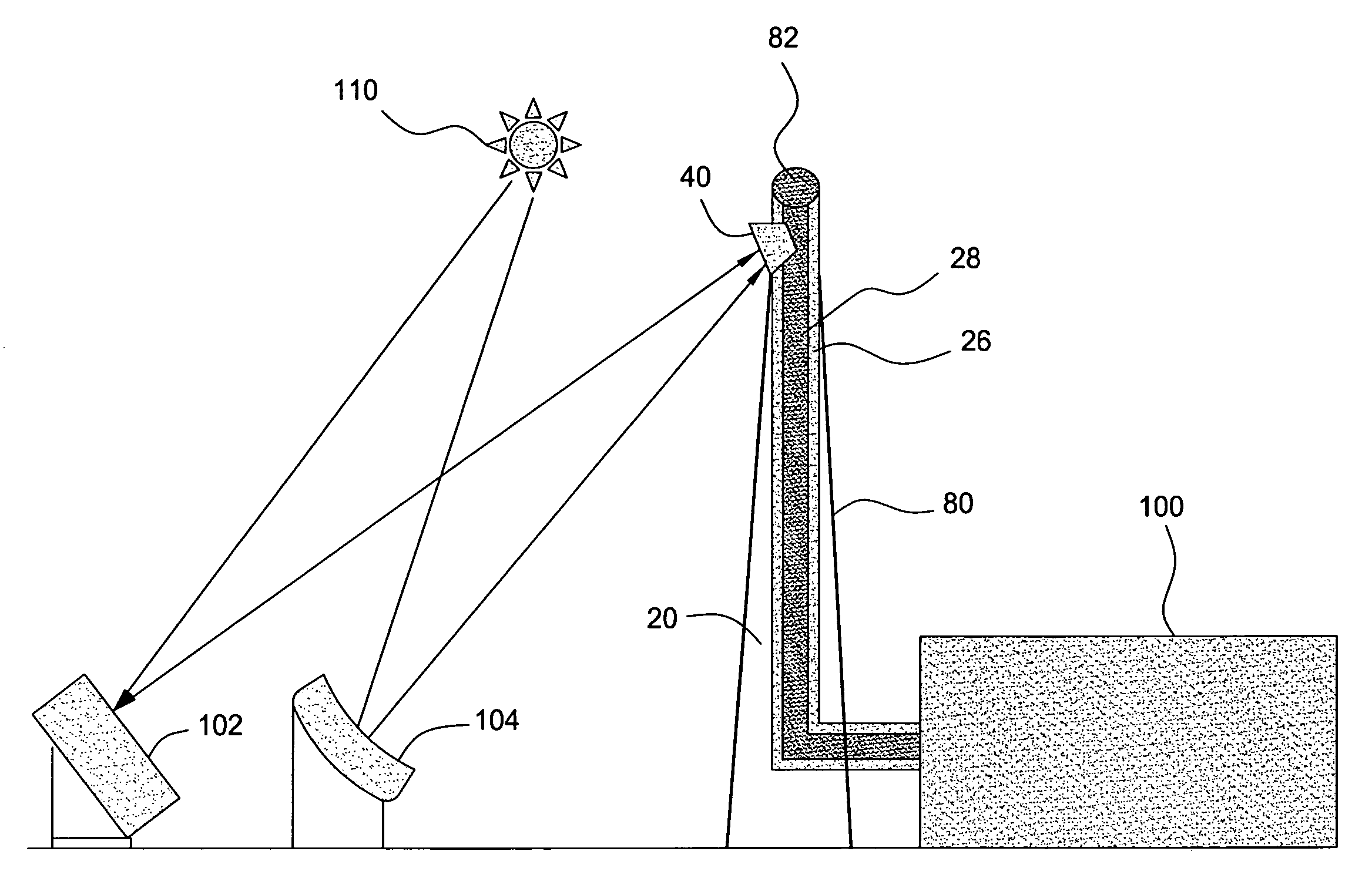

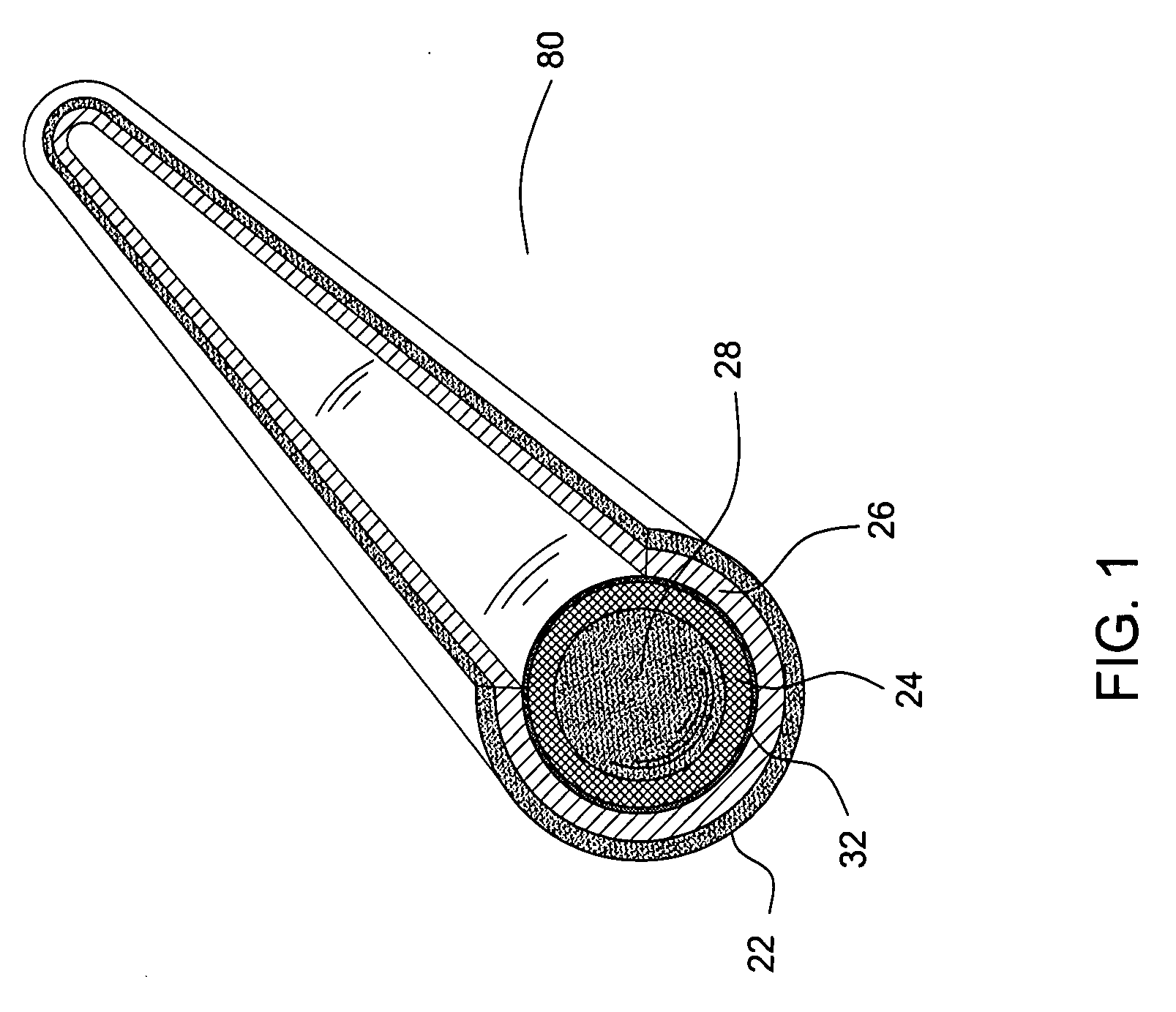

[0024] Reference is now made to FIG. 1 in which a dual walled conveyance forming a high-temperature energy transportation pipeline 20 is shown which comprises an outer tubing 22 and an inner tubing 24, having a gap therebetween forming a flow annulus 26. Within inner tubing 24 is provided a flow conduit 28. Both the outer tubing 22 and the inner tubing 24 may be constructed from materials such as carbon steel and others well known to one skilled in the art. Pipeline 20 enables the delivery of a fluid, or gas to a location, and passage of that fluid back to its origin through the pipeline 20. To accomplish this, and to minimize temperature change of the returning fluid, the flow annulus 26 is used to transport cooler fluids and the flow conduit 28 is used to transport hotter fluids. Such fluids include water / steam, air, helium, argon, and molten salts. To help increase the likelihood of a constant temperature differential between the flow volume 28 and the flow annulus 26 a high effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com