Impeller for fuel pump and fuel pump in which the impeller is employed

a technology of impeller and fuel pump, which is applied in the direction of liquid fuel engines, machines/engines, liquid fuel feeders, etc., can solve the problems and achieve the effect of restricting a decrease in pump efficiency and reducing the peak of a sound pressure of a nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

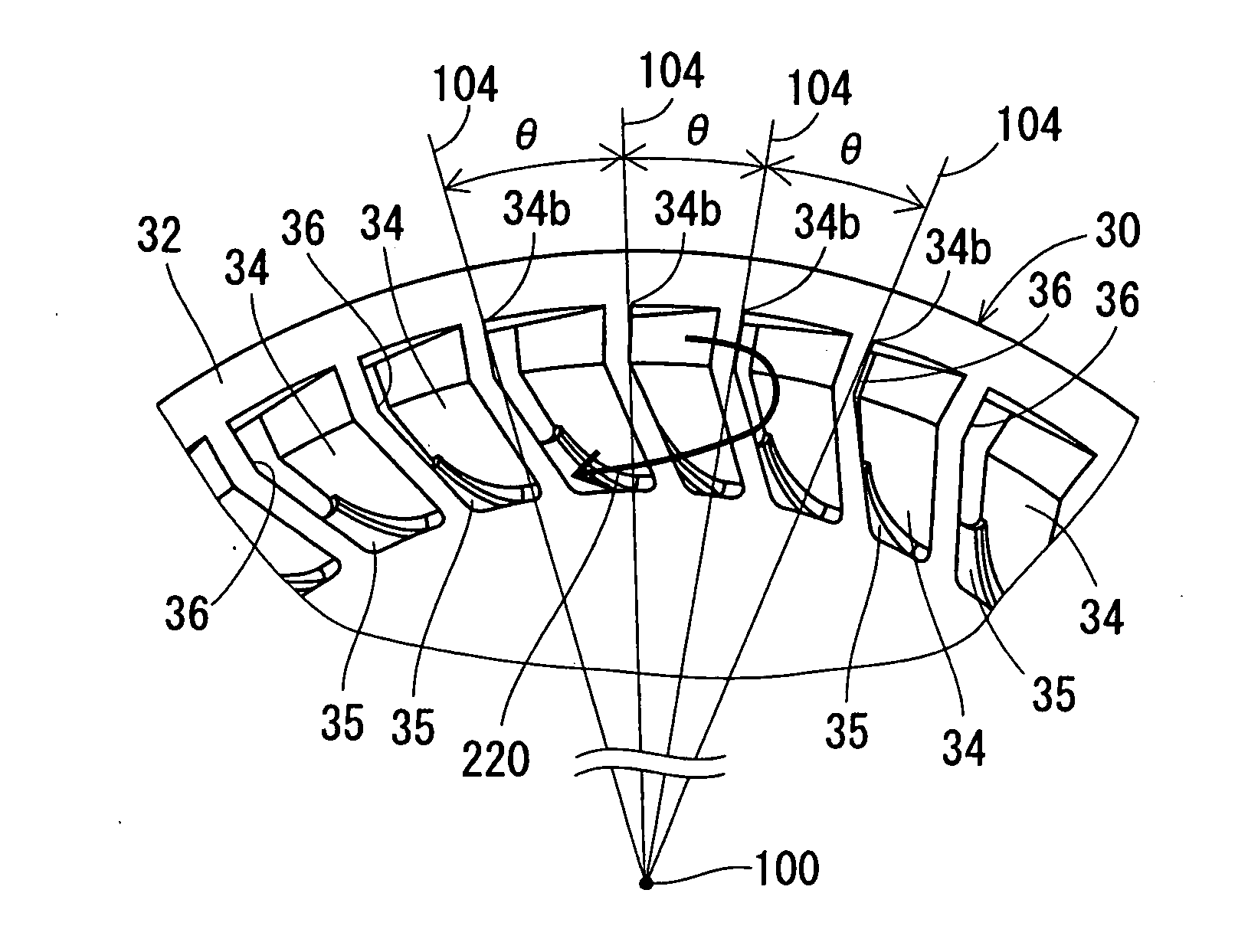

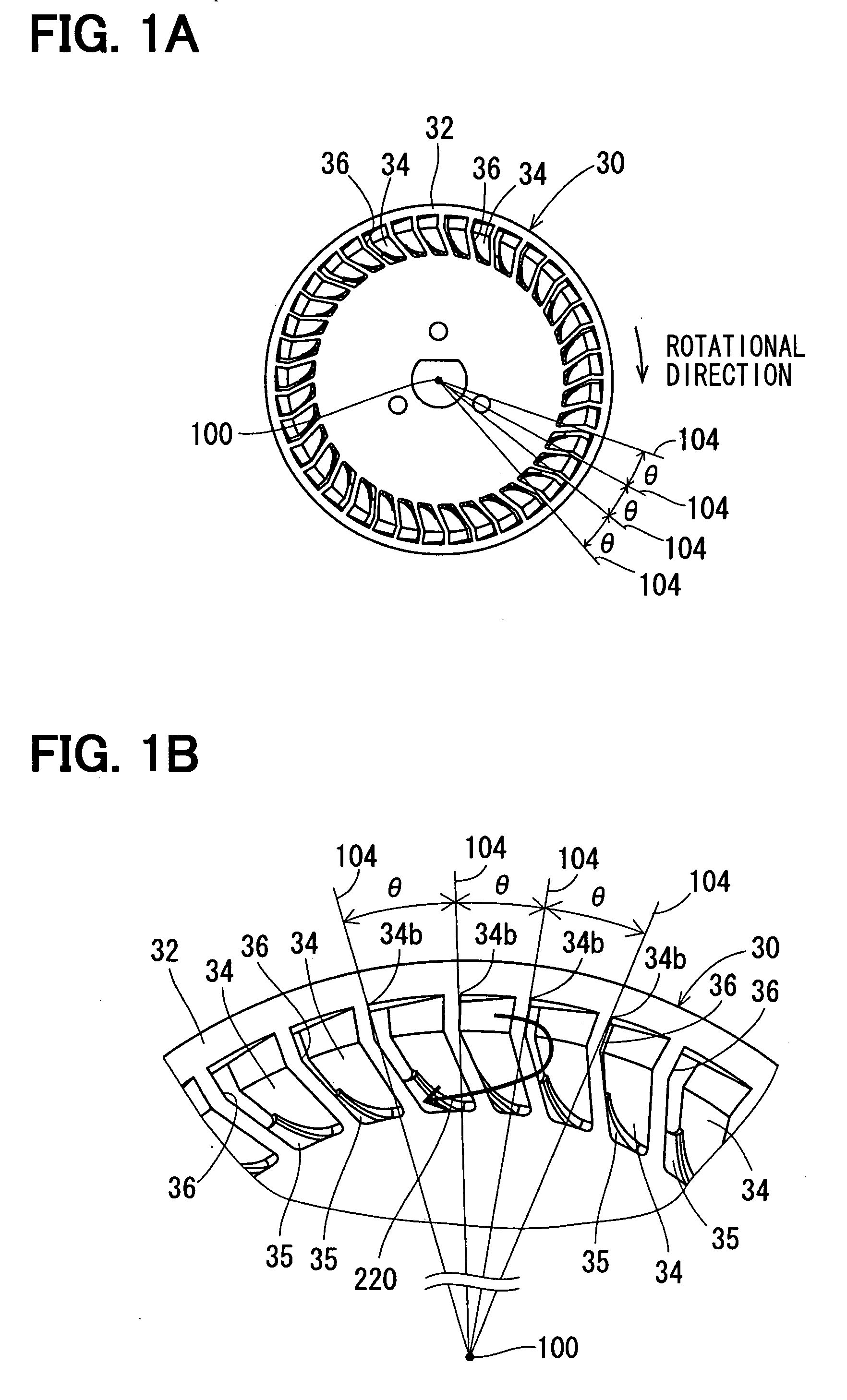

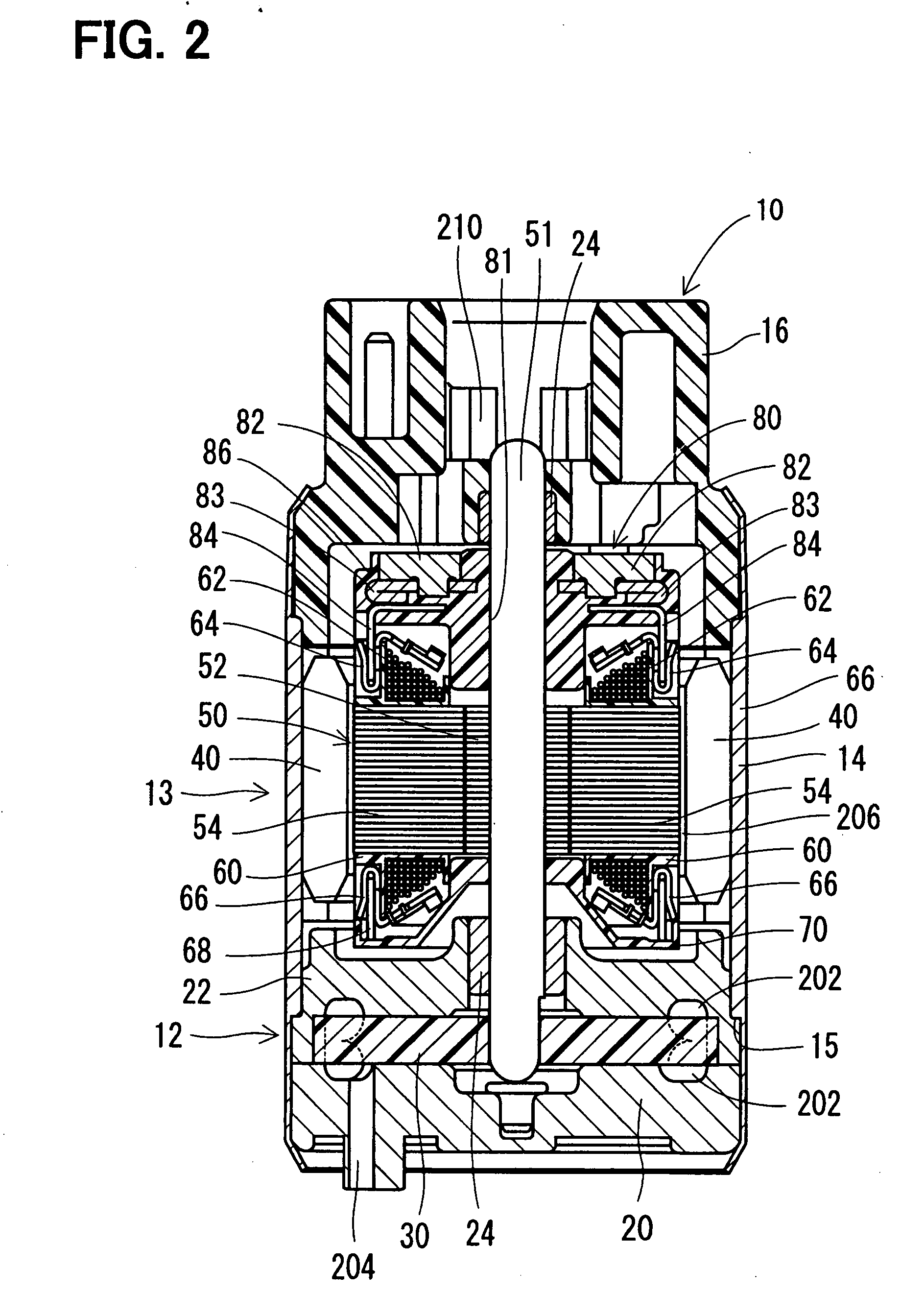

[0025]FIG. 2 shows a fuel pump 10, in which an impeller 30 according to a first embodiment of the present invention is employed. The fuel pump 10 is, for example, an in-tank turbine pump, which is attached to an inside of a fuel tank of a vehicle or the like. The fuel pump 10 supplies fuel in the fuel tank to a fuel injection valve (not shown). The fuel pump 10 is set such that its discharge pressure includes a range of 0.25 to 1 [Mpa], its discharge rate includes a range of 50 to 250 [L / h], and its rotational speed includes a range of 4000 to 12000 [rpm].

[0026]The fuel pump 10 includes a pump unit 12 and a motor unit 13, which drives the pump unit 12 to rotate. A housing 14 is for the pump unit 12 and the motor unit 13, and caulks an end cover 16 and a pump case 20.

[0027]The pump unit 12 is a turbine pump, which has the pump case 20, a pump case 22 and the impeller 30. The pump case 22 is press-fitted into the housing 14, and is pressed on a stage part 15 of the housing 14 in an ax...

second embodiment

[0048]FIG. 7 shows a second embodiment of the present invention. The same numerals are used to indicate substantially the same components as the first embodiment described above. In the second embodiment, a configuration of a fuel pump, in which an impeller 90 is employed, is substantially the same as the first embodiment.

[0049]In the impeller 30 of the first embodiment, the radially outer part of the vane grooves 36 is surrounded by the annular part 32. In the impeller 90 of the second embodiment, on the other hand, radially outer parts of vane grooves 92 is open. Two vane grooves 92 adjacent to each other in a rotational direction of the impeller 90 are divided by a vane 94.

[0050]In the second embodiment as well, adjacent vane angles θ of the vanes 94 and their dispersion range are set in a range of 8°≦adjacent vane angle≦12°, and 2.5°≦dispersion range≦4°, respectively.

Other Embodiments

[0051]Although the dispersion range and the adjacent vane angle θ are set in the range of 2.5°≦d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com