Heating and cooling device

a cooling device and cooling element technology, applied in the direction of light and heating apparatus, machine operation mode, transportation and packaging, etc., can solve the problems of increase of the cost of manufacturing the heating and cooling device, and overheating etc., to achieve the effect of reducing the abnormal temperature increase of the peltier elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

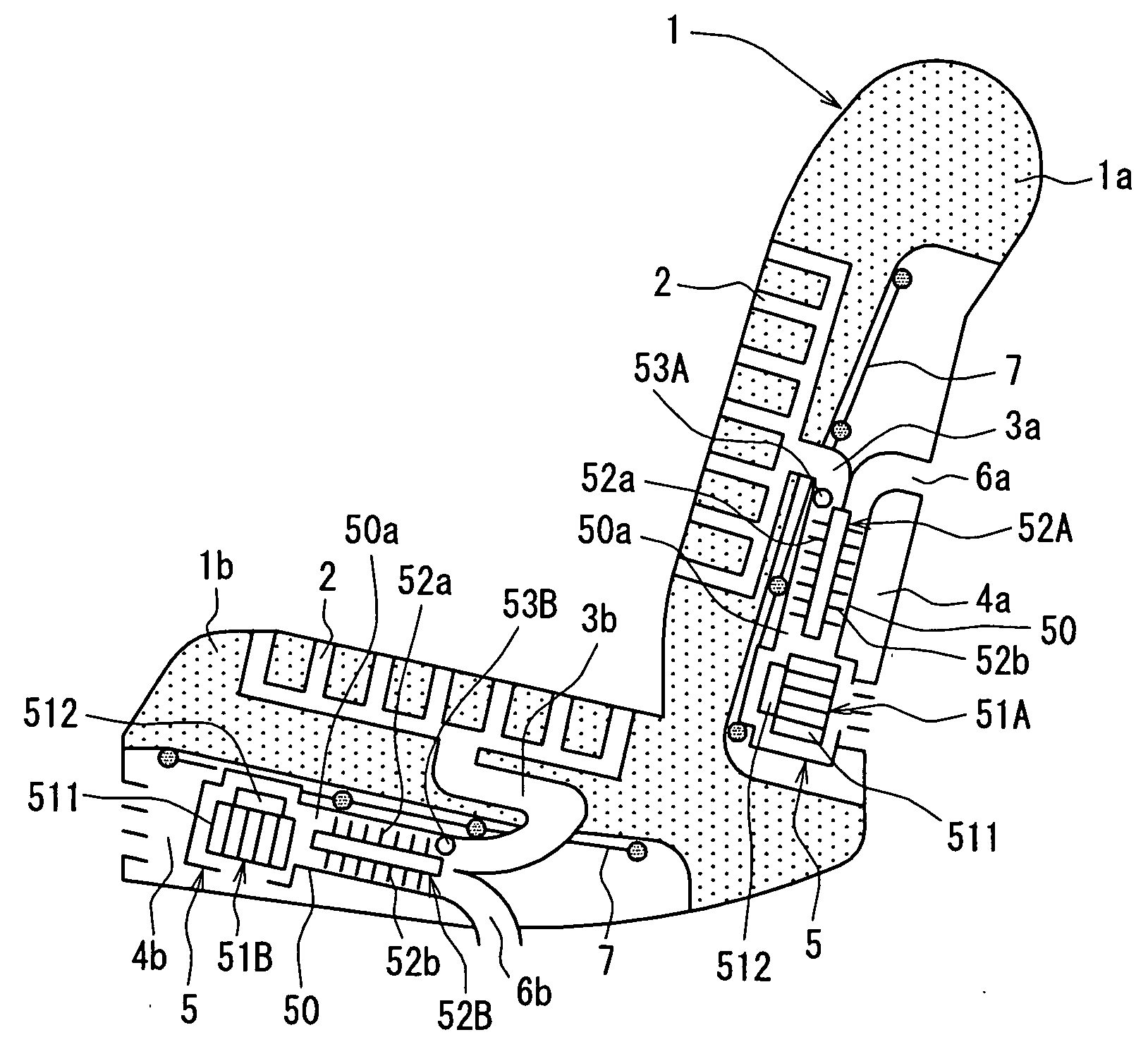

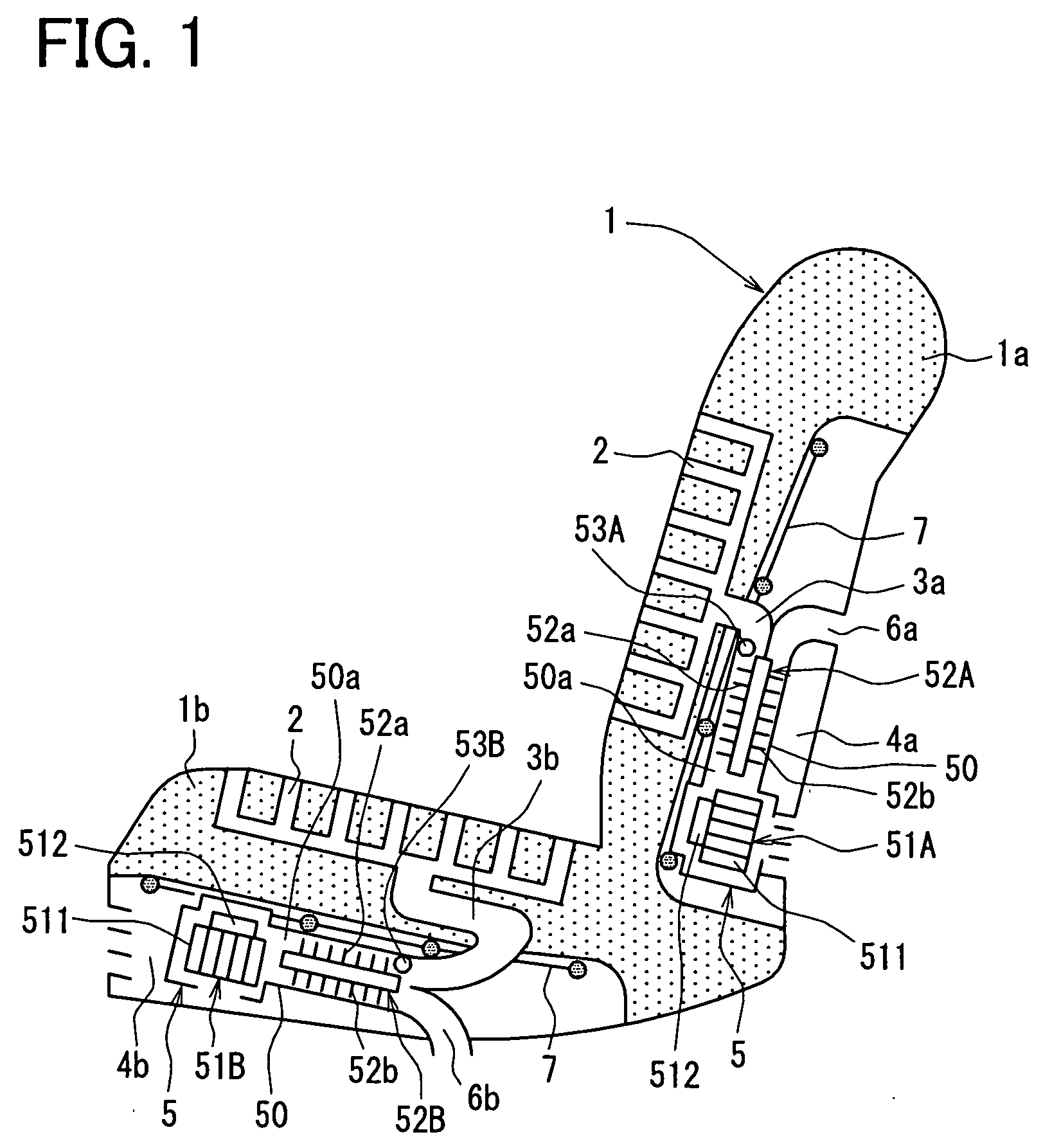

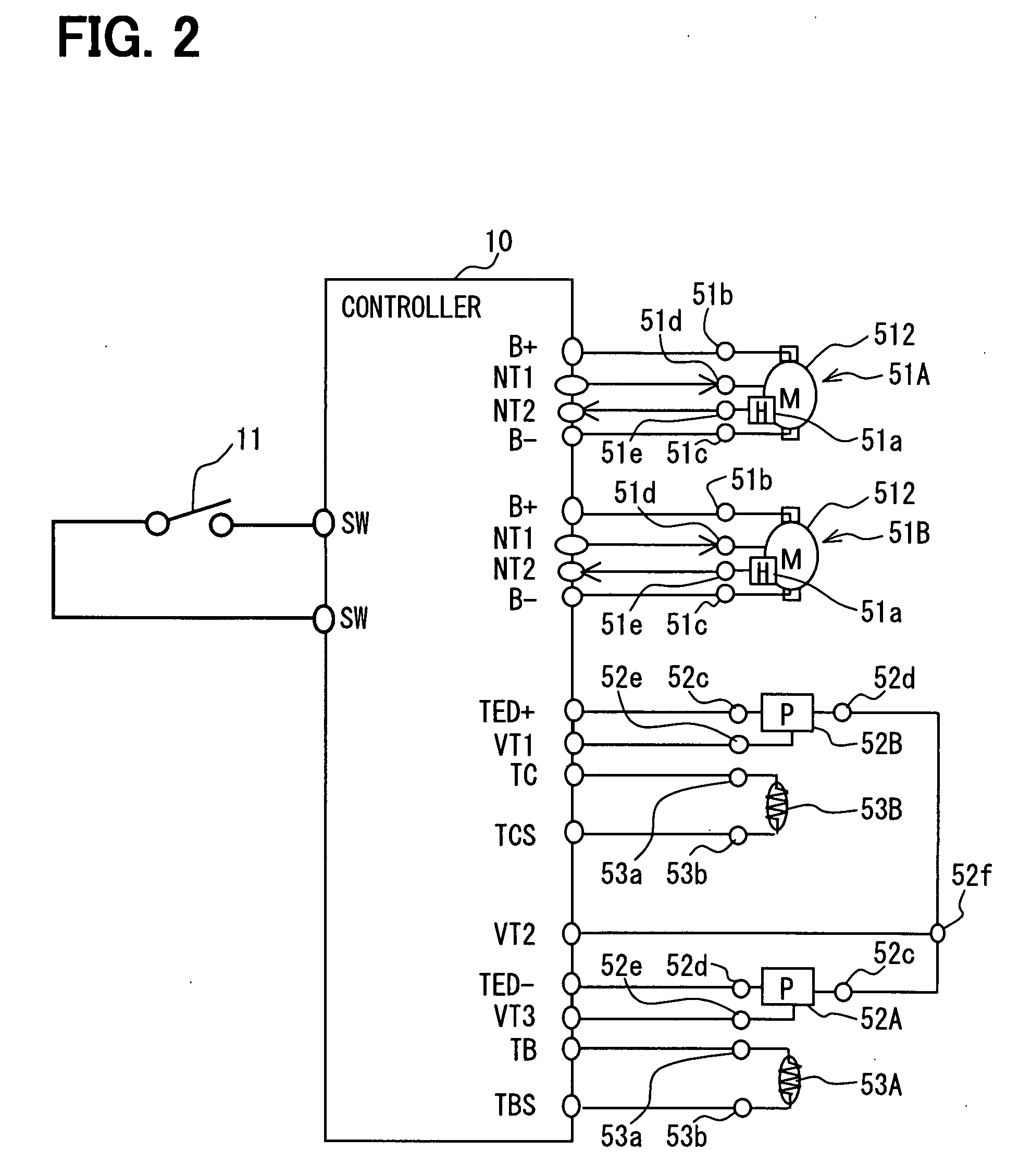

[0022]A first embodiment will be described with reference to FIGS. 1-3. As shown in FIG. 1, a seat 1 includes a seat back 1a and a seat bottom 1b, and a heating and cooling device 5 is used in each of the seat back 1a and the seat bottom 1b. A first space 4a is provided in the seat back 1a, and a second space 4b is provided in the seat bottom 1b. A controller 10 shown in FIG. 2 controls the heating and cooling device 5.

[0023]A first duct 3a communicating with the first space 4a is provided in the seat back 1a, and plural air-blowing holes 2 communicating with the first duct 3a are provided in the seat back 1a. A second duct 3b communicating with the second space 4b is provided in the seat bottom 1b, and plural air-blowing holes 2 communicating with the second duct 3b are provided in the seat bottom 1b.

[0024]The heating and cooling device 5 is arranged in each of the first space 4a and the second space 4b. Specifically, the heating and cooling device 5 is supported by a net-shaped s...

second embodiment

[0060]A second embodiment will be described with reference to FIGS. 4-6. As shown in FIG. 4, a duct 54 is disposed between the blower 51A, 51B and the Peltier element 52A, 52B in the second embodiment.

[0061]Specifically, the duct 54 has a wave shape. An end of the duct 54 is connected to a discharge side of the blower 51A, 51B, and the other end of the duct 54 is connected to the case 50 of the Peltier element 52A, 52B. Thereby, the heating and cooling device 5 can be easily mounted in the space 4a, 4b of the seat 1 having a complicated shape.

[0062]When electricity is supplied to the Peltier element 52A, 52B, the duct 54 may be disconnected (detached) by vibration of the vehicle. The disconnection of the duct 54 can be detected in the second embodiment.

[0063]Specifically, as shown in FIG. 5, step 165 is provided between step 160 and step 170. At step 165, the number N of revolutions of the detected revolution signal input at step 160 is compared with a predetermined number R2 of rev...

third embodiment

[0069]A third embodiment will be described with reference to FIGS. 7 and 8. In the above embodiments, the hall element 51a detects the driving state of the blower 51A, 51B, when a brushless motor is used as the motor 512. However, when a motor having brush is used as the motor 512, current flowing through the blower 51A, 51B can be detected.

[0070]Specifically, as shown in FIG. 7, the controller 10 has the positive electrode side power terminal B+, the negative electrode side power terminal B− and a driving current input terminal Ip, in order to be connected to the motor 512 of the blower 51A, 51B. Further, the motor 512 of the blower 51A, 51B has the power input terminal 51b, the power output terminal 51c and a driving current detection terminal 51f.

[0071]The power input terminal 51b is connected to the positive electrode side power terminal B+. The power output terminal 51c is connected to the negative electrode side power terminal B−. The driving current detection terminal 51f is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com