Tactical sight for a semi-automatic hand gun

a semi-automatic handgun and sight technology, applied in the field of semi-automatic handguns, can solve the problems of reducing the ability to fully see the target, reducing the time necessary to locate the front sight, and reducing the ability to see the threat about the peripheral parts of the sight, so as to reduce the obstruction of the sight, direct and focus the user's sight quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

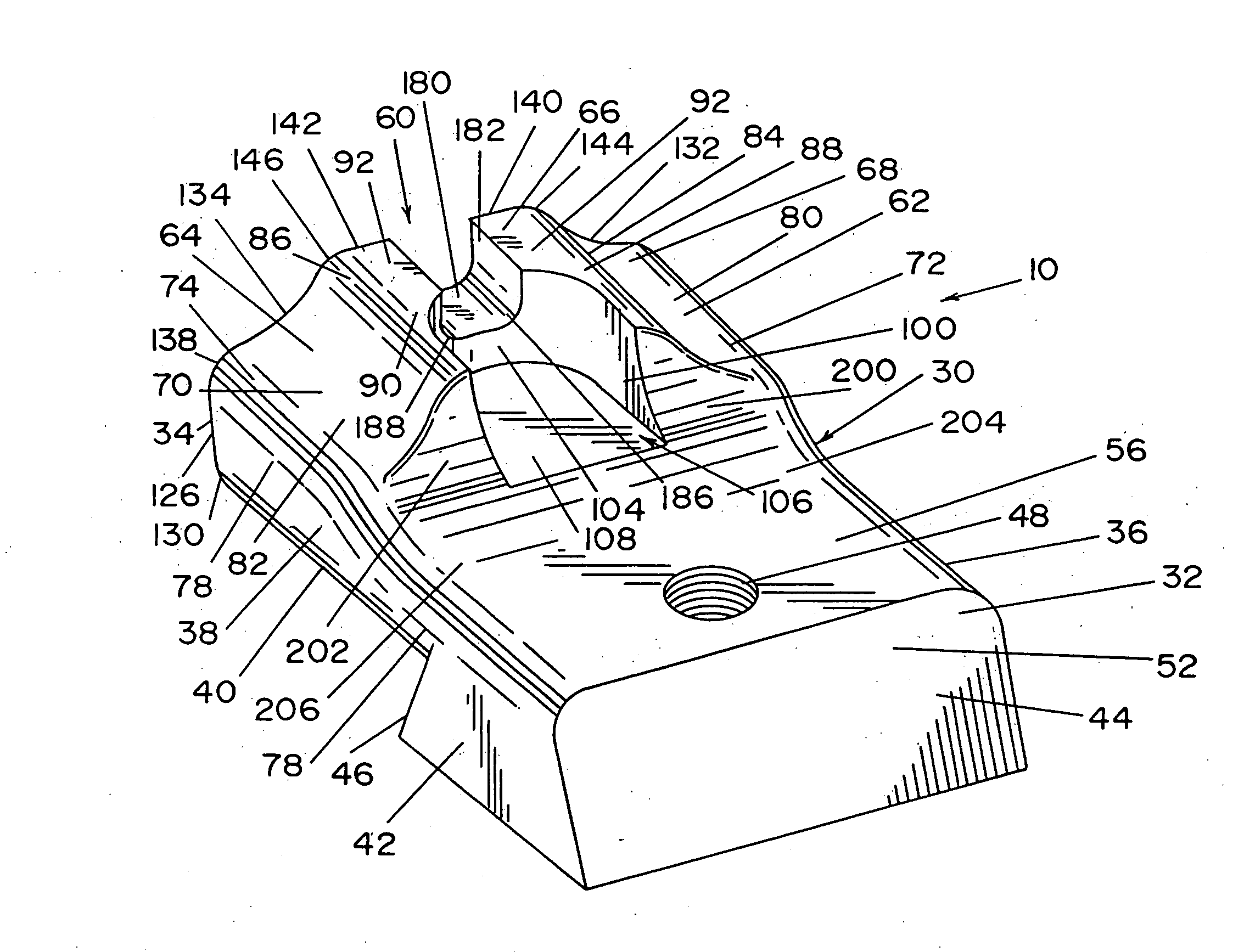

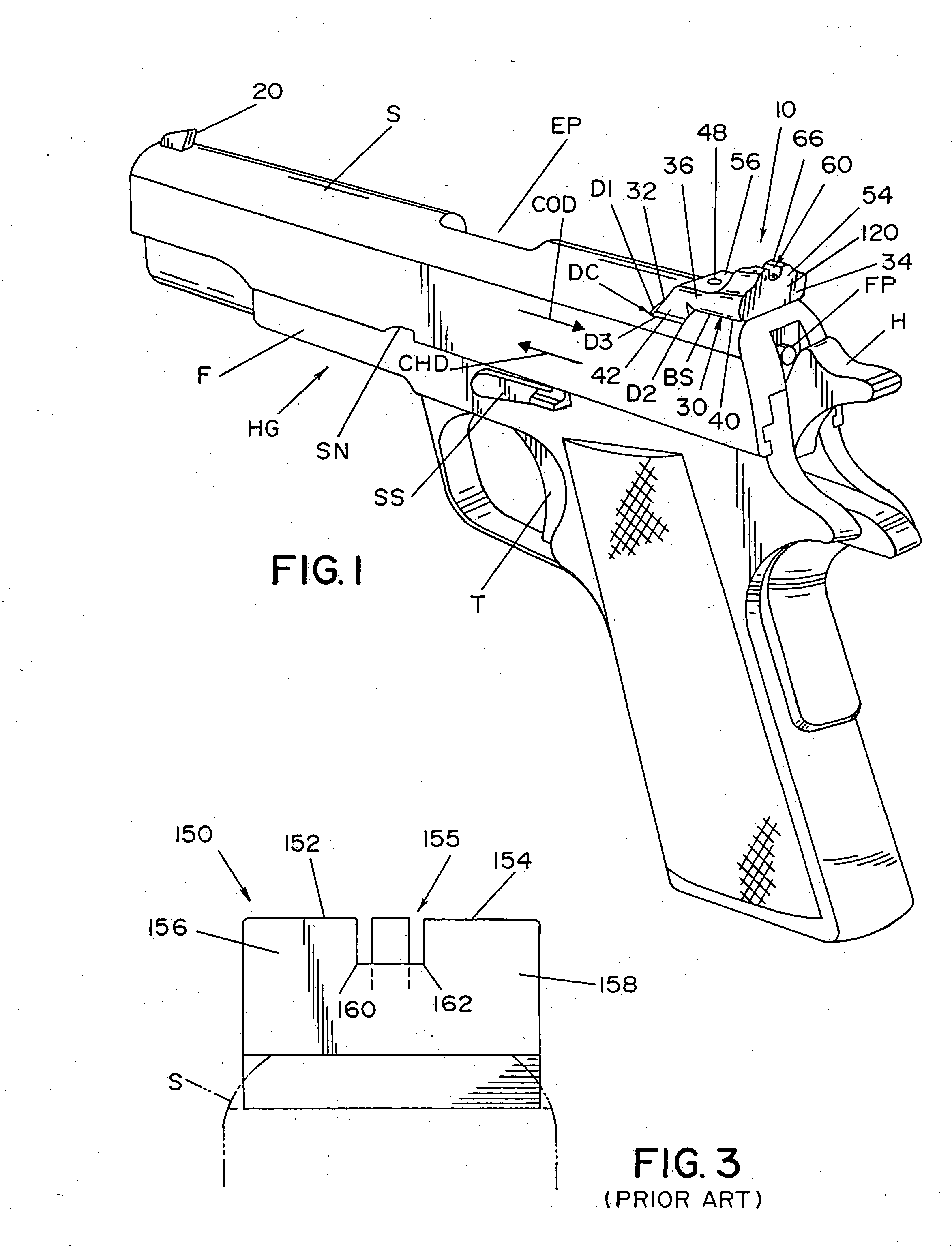

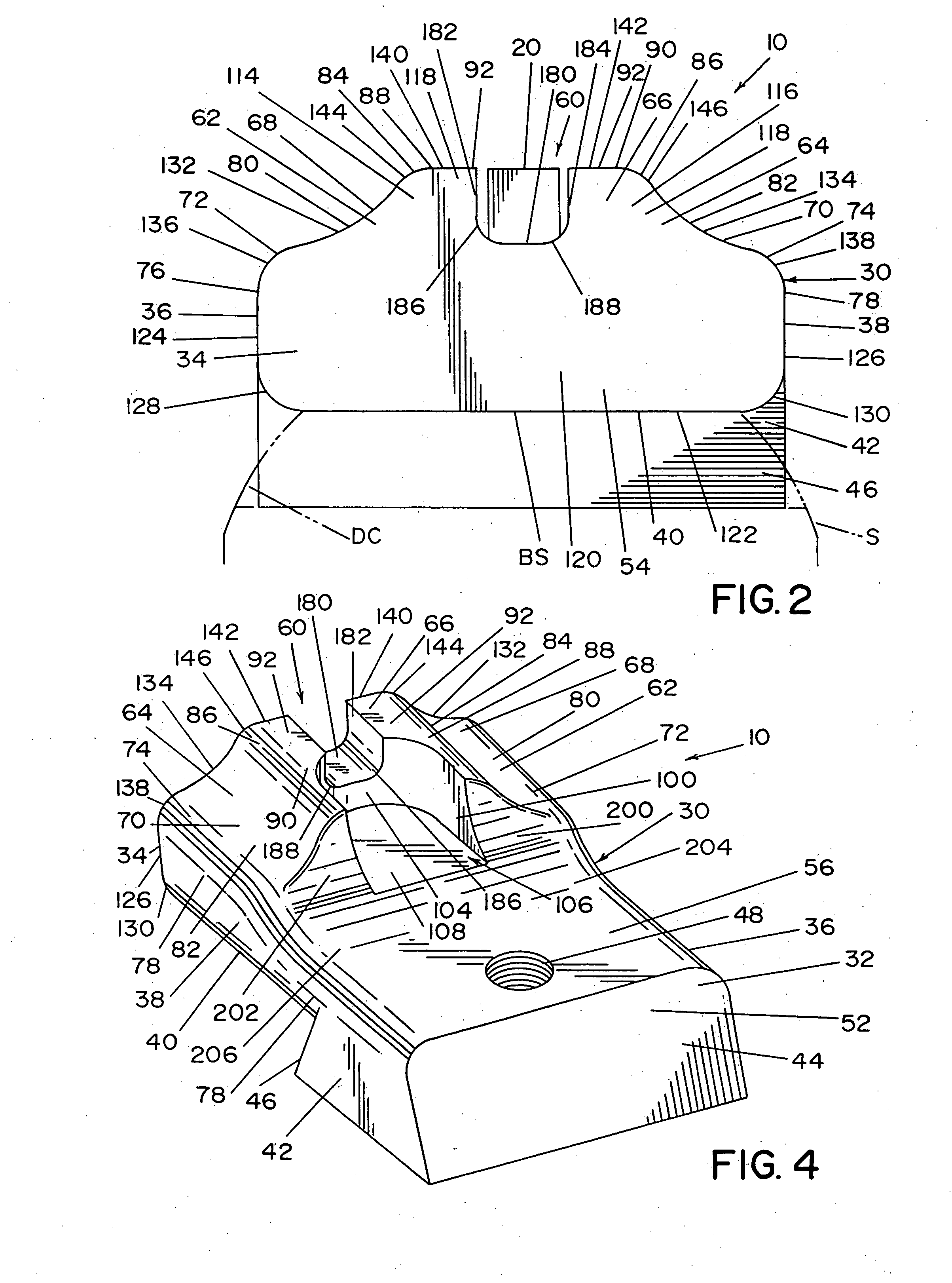

[0030] Referring now in greater detail to the drawings wherein the showings are for the purpose of illustrating preferred embodiments of the invention only, and not for the purpose of limiting the invention, FIG. 1 shows a semi-automatic handgun HG and slide S with a rear tactical sight 10 and a front tactical sight 20 mounted thereon. A dovetail cut DC and a base surface BS are machined into a portion of the top surface of slide S which allows rear sight 10 to be rigidly secured to slide S and to be precisely oriented relative to a barrel (not shown) for firing accuracy. However, while a dovetail may be preferred, it is not necessary for the invention of this application.

[0031] Slide S moves relative to a frame F of handgun HG rearwardly in a cocking direction COD to extract and eject a spent cartridge (not shown) from the barrel and to simultaneously cock a hammer H. When this rearward motion is complete, slide S then moves forwardly in a chambering direction CHD to chamber a new...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com