Multipurpose apparatus for mounting objects and repairing drywall

a multi-purpose, drywall repair technology, applied in the direction of walls, building materials handling, construction, etc., can solve the problems of drywall damage, need repair, easy damage, etc., to facilitate the user in quickly and easily separating the mounting apparatus, simple, quick and inexpensive, and non-invasive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

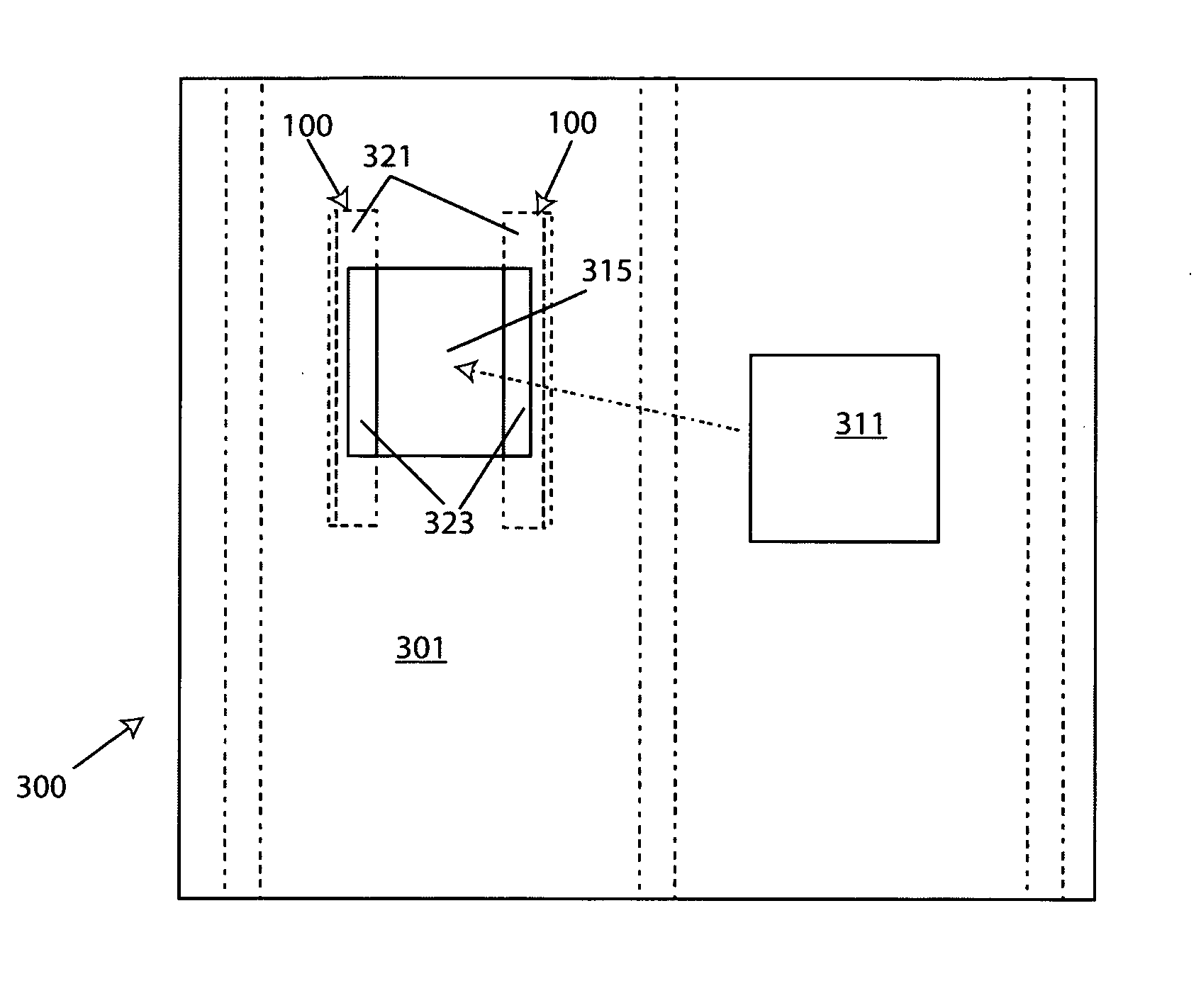

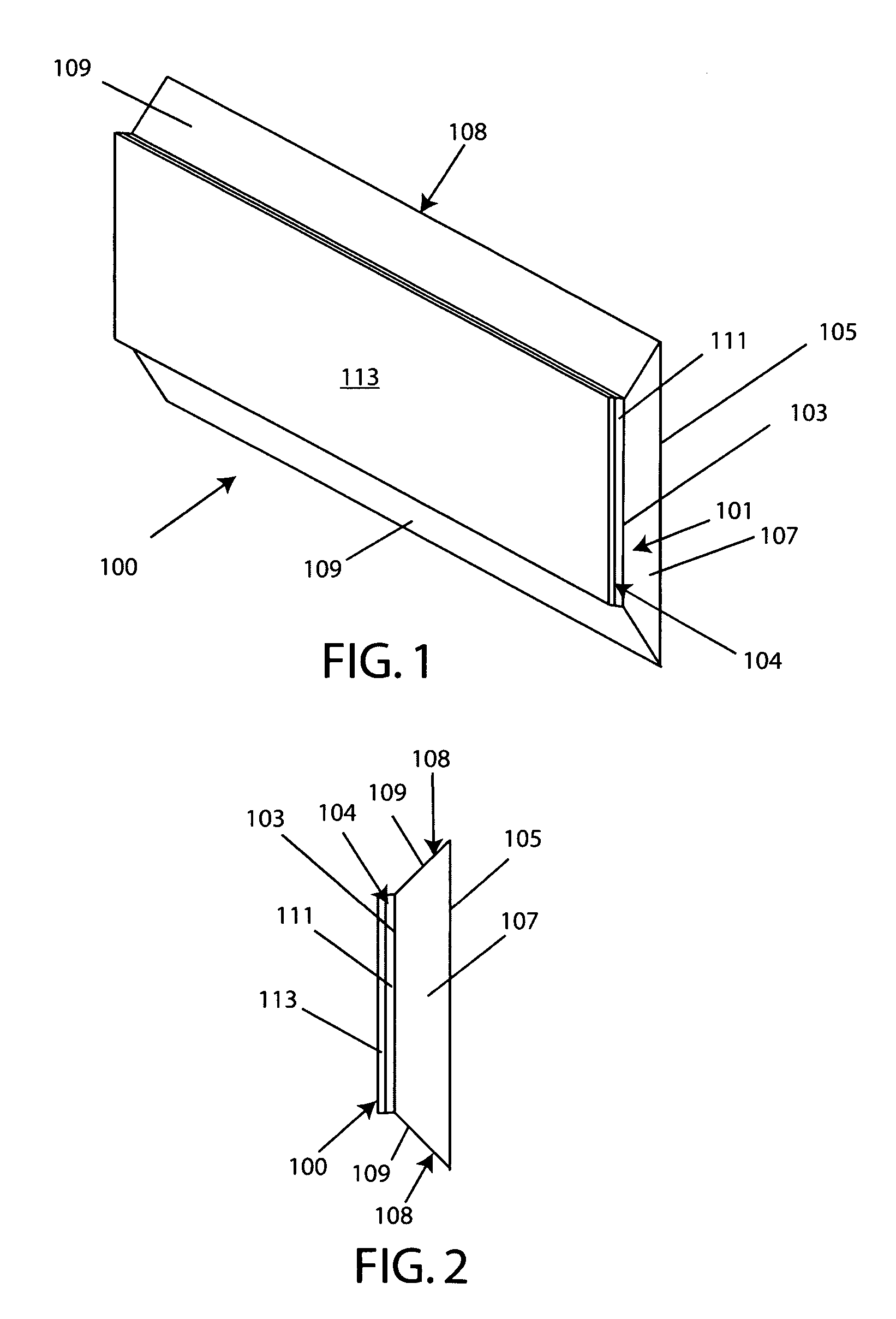

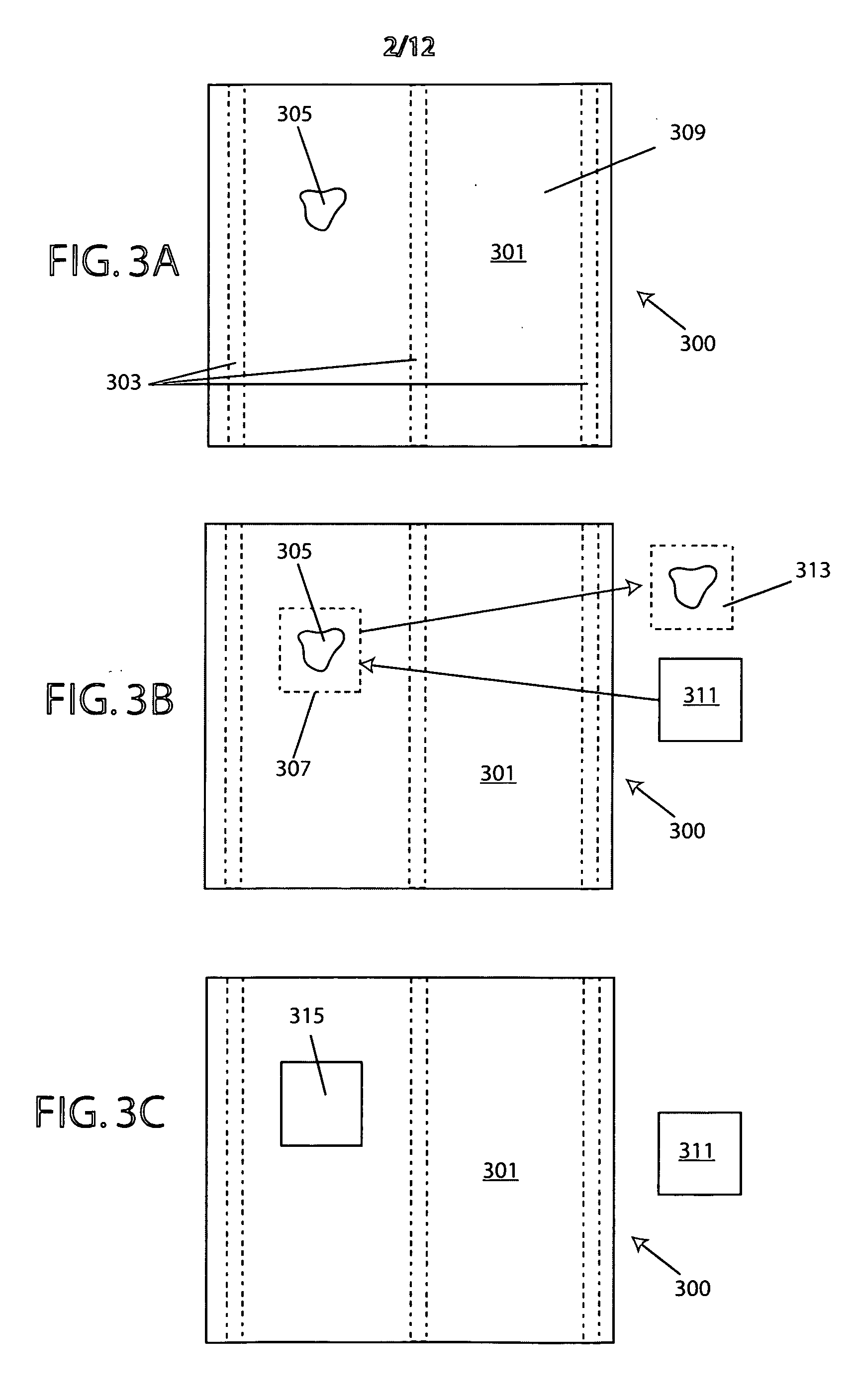

[0038] Generally speaking, the apparatus, systems and methods taught herein are directed to mounting devices and systems. By applying what is taught herein, objects can quickly and easily be mounted to a desired mounting surface without the need of tools or an invasive technique. In addition, a simple and efficient method for repairing drywall is shown.

[0039] As required, exemplary embodiments of the present invention are disclosed. These embodiments are provided as examples of various embodiments of the invention and it will be understood that the invention may be embodied in alternative forms. The figures are not to scale and some features may be exaggerated or minimized to show details of particular elements, while related elements may have been eliminated to prevent obscuring novel aspects. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as a representative basis for teaching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com