Determination of remaining useful life of gas turbine blade

a technology of gas turbine blades and useful life, which is applied in the direction of material analysis using wave/particle radiation, instruments, and static/dynamic balance measurement, etc., can solve the problems of turbine blades that fail at a much less stress than the turbine blade can withstand, damage growth on the vibration characteristics of turbine blades, and deterioration of turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

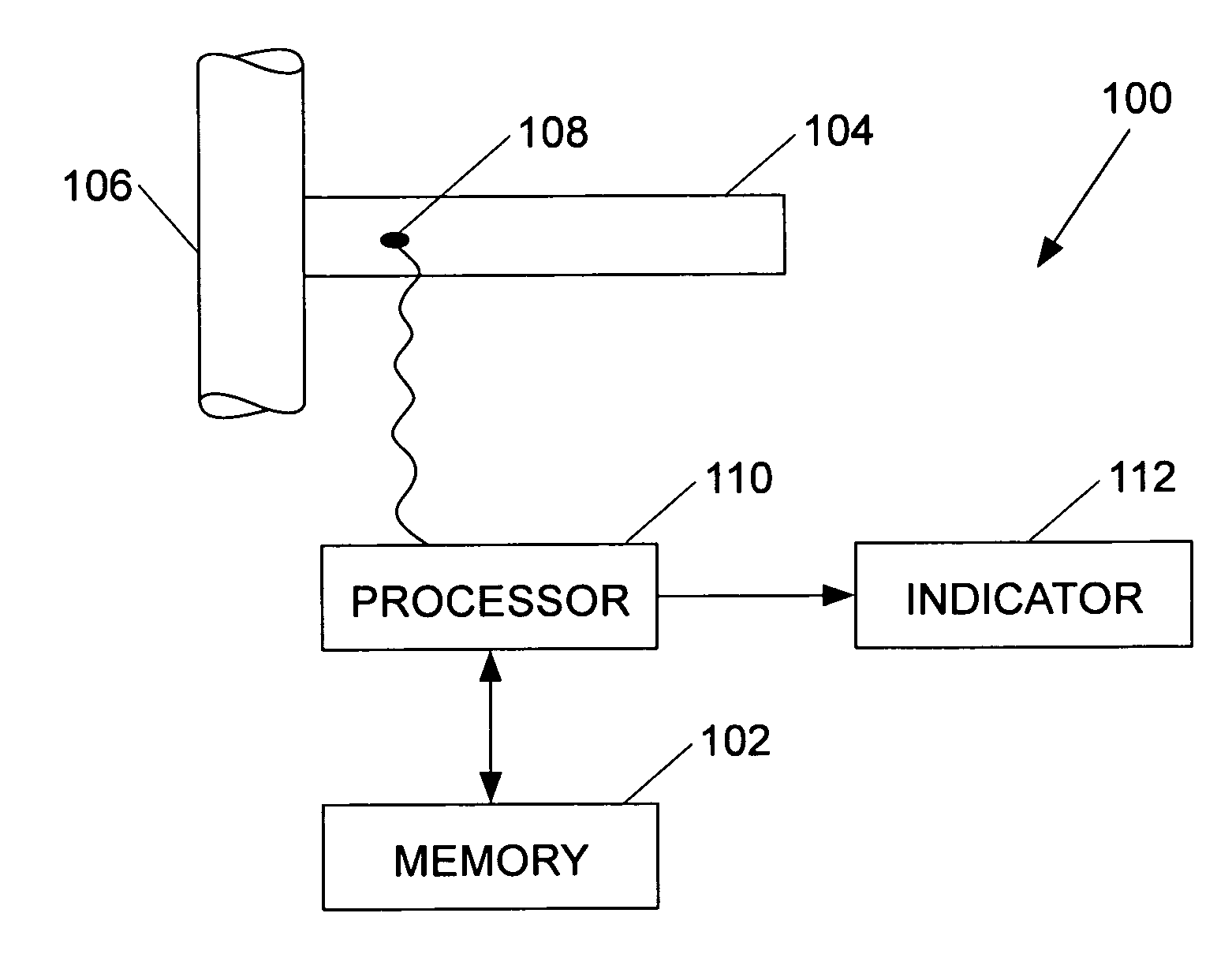

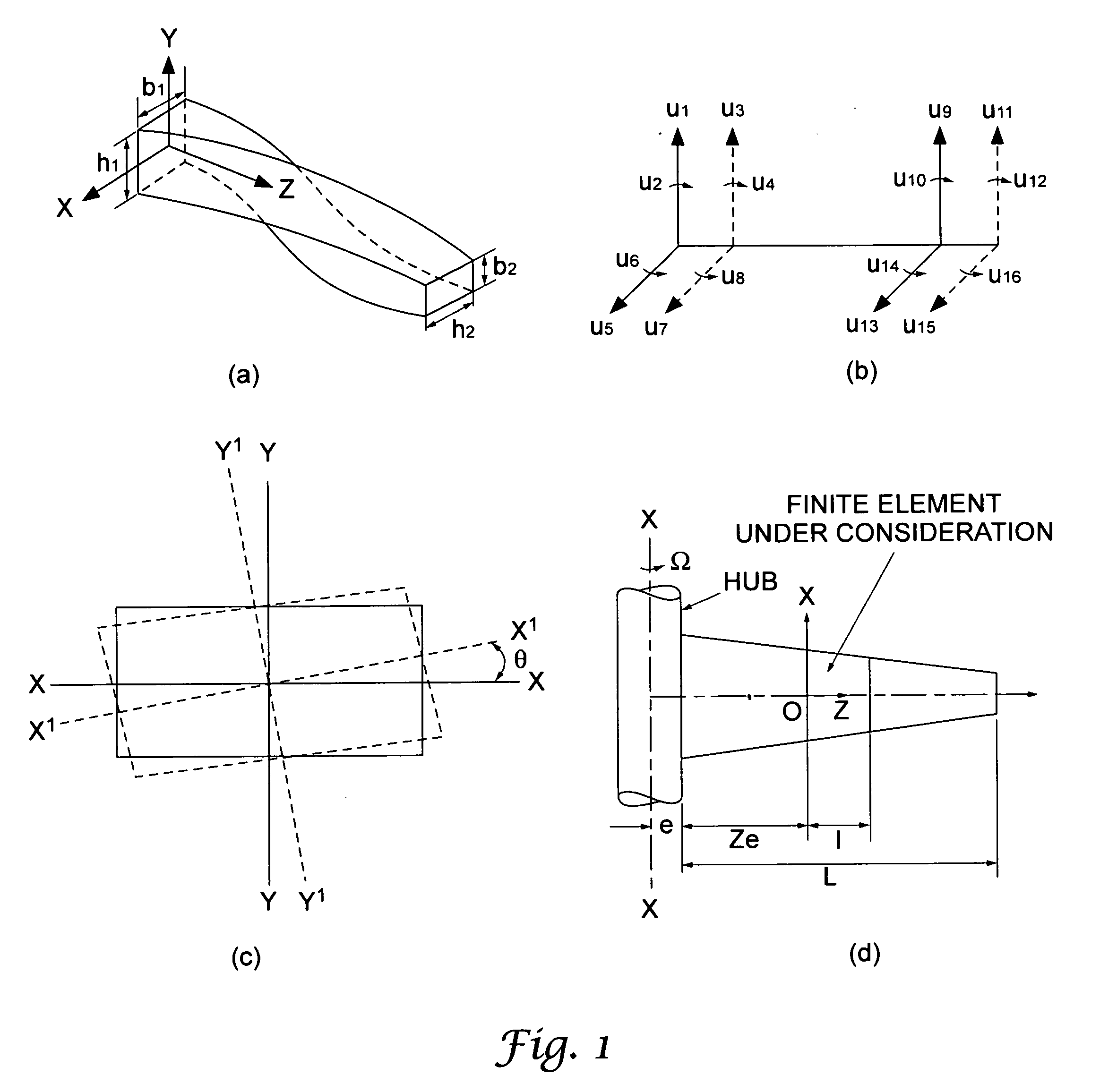

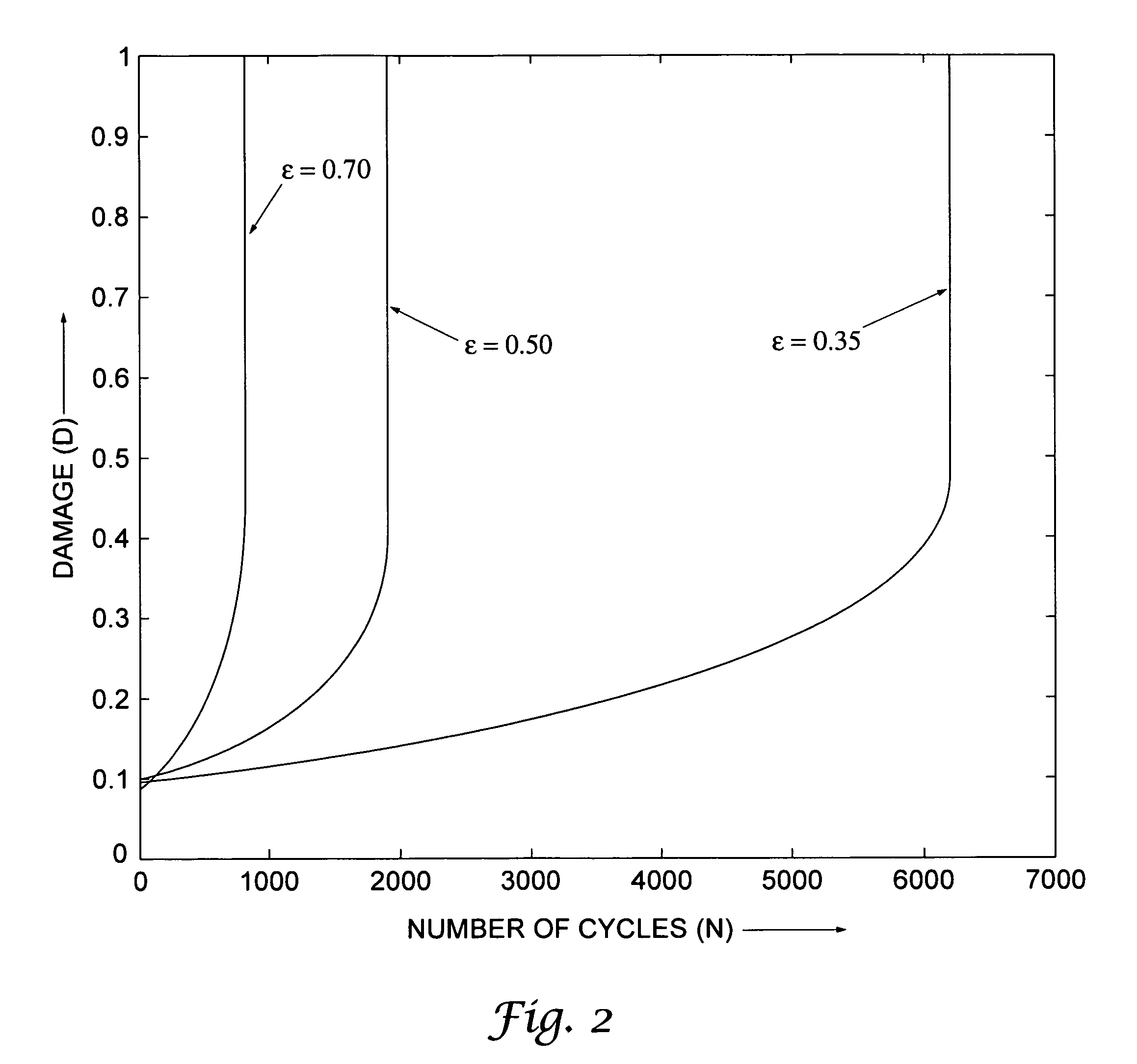

[0017]Fatigue is a phenomenon in which repetitive loads cause a structure to fail at a stress level that is much lower than the stress level that the structure can withstand when it is new and unused. The principal contributing factors to fatigue failure are the number of load cycles experienced by the structure and the presence of local stress concentrations. Fatigue cracks result from plastic deformation, which in turn results from initiation and propagation of a crack. Low cycle fatigue is associated with large stresses causing considerable plastic deformation with failure cycles Nf in the range of 102 to 104.

[0018]The Table defines certain parameters, variables, and constants used in the analysis presented herein.

AArea of cross sectionbBreadth of beamDDamage variableD0Initial damageeOffsetEYoung's modulusE0Young's modulus for undamaged materialgacceleration due to gravityGShear modulushDepth of beamIxxmoment of inertia of beam cross section about xxaxisIyymoment of inertia of be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com