Refrigerant cycle device and heat-exchanger integrated unit with temperature sensor for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

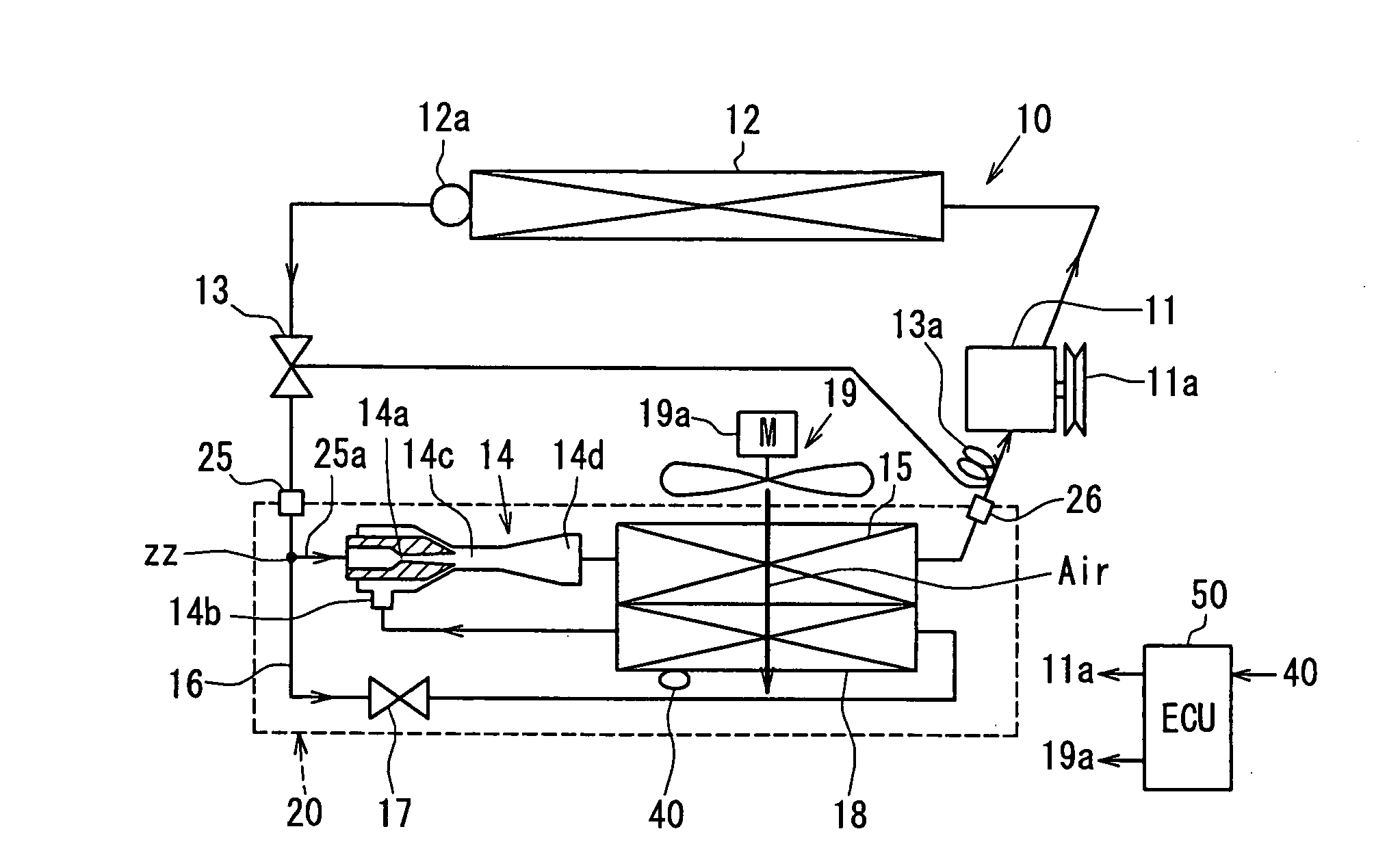

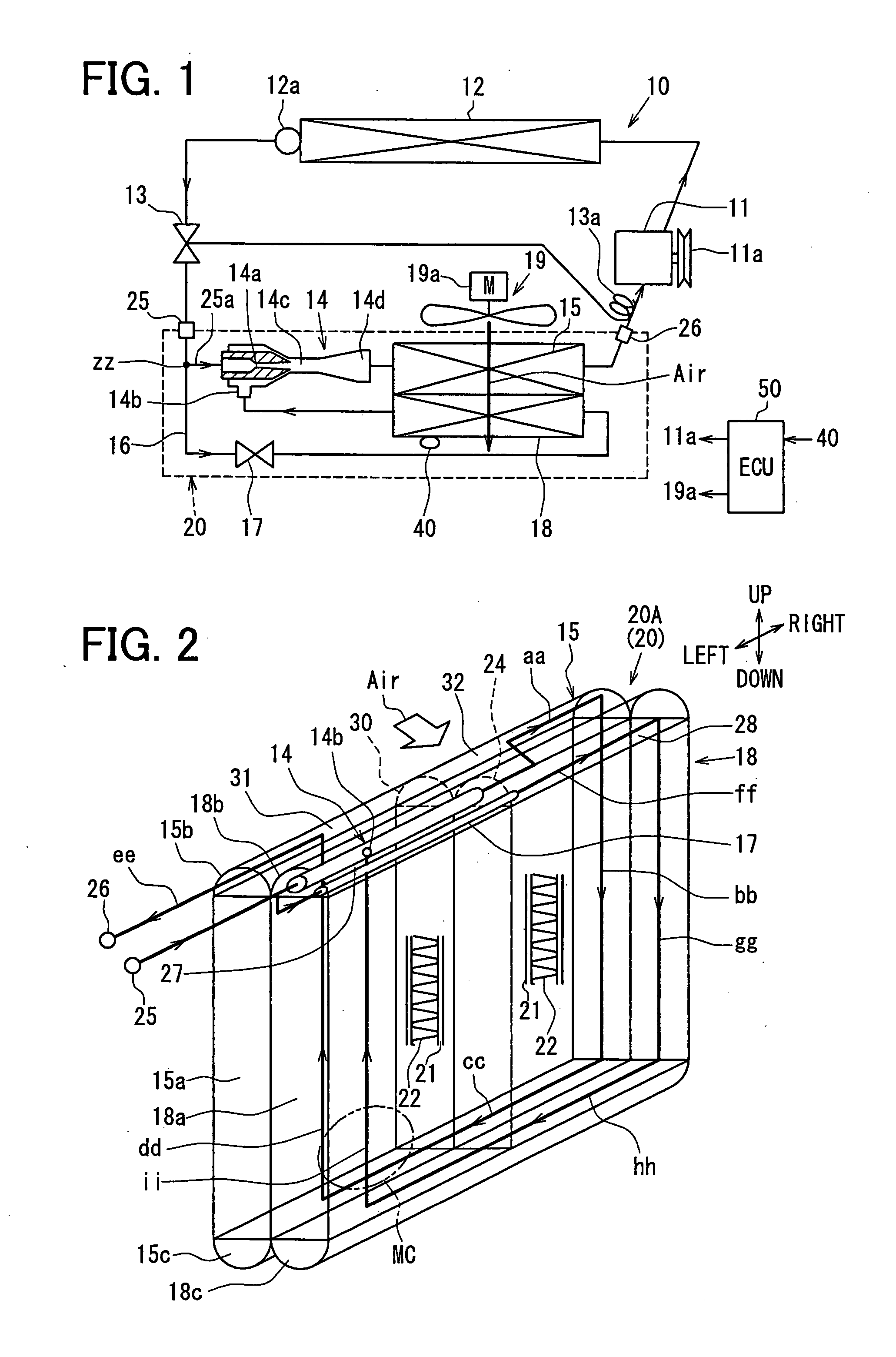

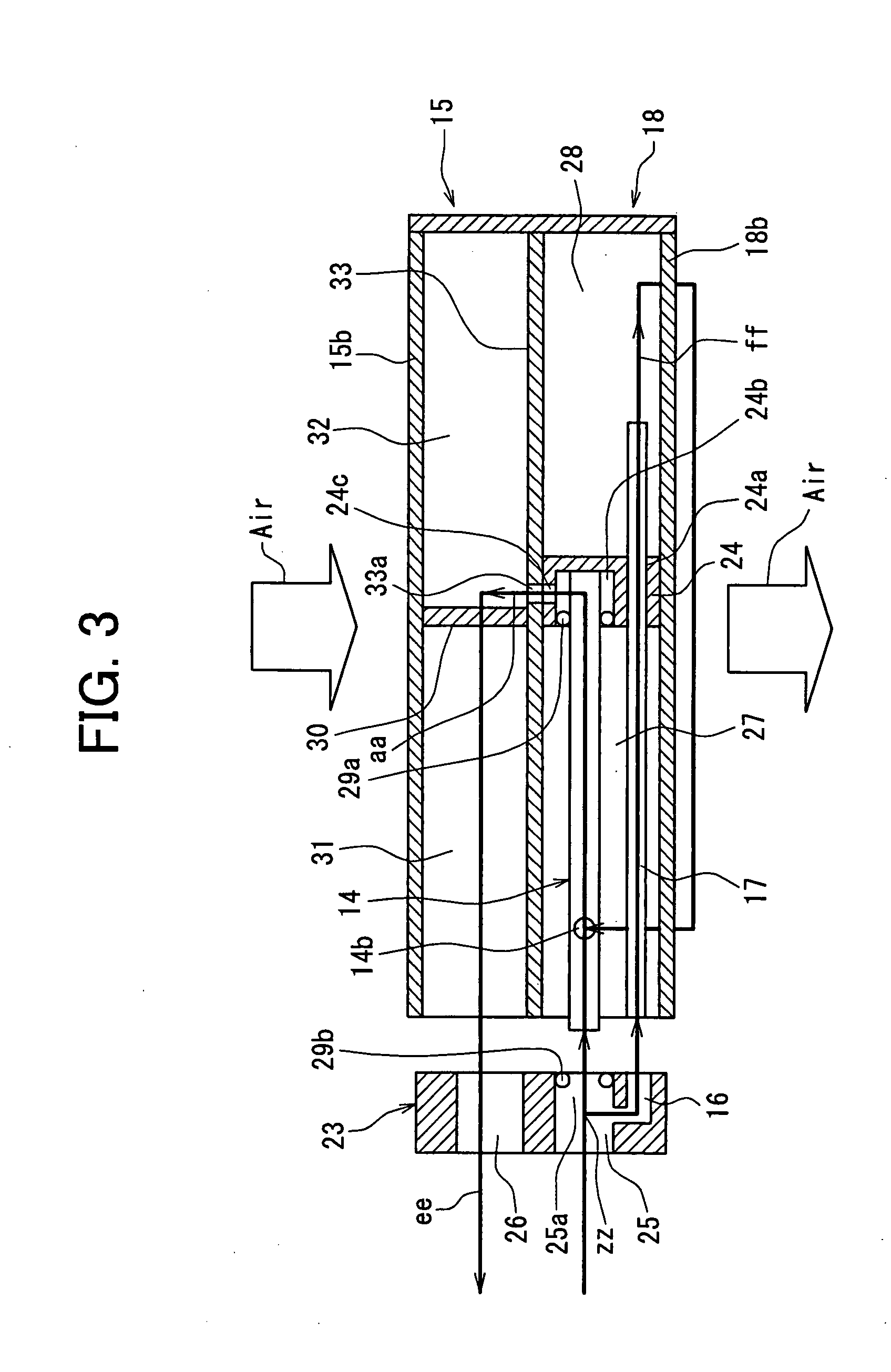

Method used

Image

Examples

first modification

(First Modification)

[0111]FIG. 10 shows an integrated unit 20B (20) of the first modification.

[0112]As shown in FIG. 10, a separator 15e is disposed in the upper tank portion 15b of the first evaporator 15 to partition the inner space of the upper tank portion 15b into a left inner space C′ and a right inner space D′ such that the left space C′ occupies about one third of the inside of the upper tank portion 15b and the right space D′ occupies about two thirds thereof. A separator 15f is disposed in the lower tank portion 15c of the first evaporator 15 to partition the inner space of the lower tank portion 15c into a left inner space E′ and a right inner space F′ such that the left space E′ occupies about two thirds of the inside of the lower tank portion 15c and the right space F′ occupies about one third thereof.

[0113]Separators 18e and 18f are disposed in the upper tank portion 18b of the second evaporator 18 to partition the inside of the upper tank portion 18b into about three ...

second modification

(Second Modification)

[0127]In the above-mentioned first modified example, the ejector-type refrigerant cycle device 10 using the integrated unit 20B has been explained. However, in the second modified example, an integrated unit 20C (20) shown in FIG. 11 is used for the ejector-type refrigerant cycle device 10. FIG. 11 is a perspective view showing an outline of the entire structure of the integrated unit 20C, in which the basic structures of the first evaporator 15 and the second evaporator 18 are similar to those of the first modified example.

[0128]The integrated unit 20C of FIG. 11 differs from the integrated unit 20B of the first modified example in arrangement and positioning of the separators disposed in the tank portions 15b to 18c, as well as in arrangement and positioning of the ejector 14, and thus in the refrigerant flow path. Ah shown in FIG. 11, a separator 15e′ is disposed in the upper tank portion 15b of the first evaporator 15 to partition the inner space of the uppe...

third modification

(Third Modification)

[0138]In the above-mentioned examples, the ejector-type refrigerant cycle device 10 employing the integrated unit 20A, 20B, 20C has been explained. However, in the third modified example, an integrated unit 20D (20) shown in FIG. 12 is used for the ejector-type refrigerant cycle device 10. FIG. 12 is a perspective view showing an outline of the entire structure of the integrated unit 20D. Also in the integrated unit 20D, the ejector 14, the first and second evaporators 15 and 18, and the temperature sensor 40 are integrally constructed, like the integrated unit 20B, 20C.

[0139]The basic structures of the first and second evaporators 15 and 18 of the integrated unit 20D are the same as those of the first or second modified example. The integrated unit 20D differs from the integrated unit 20B, 20C in arrangement and positioning of the separators disposed in the tank portions 15b to 18c and in arrangement and positioning of the ejector 14. Thus, the third modified ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com