Paintball gun device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

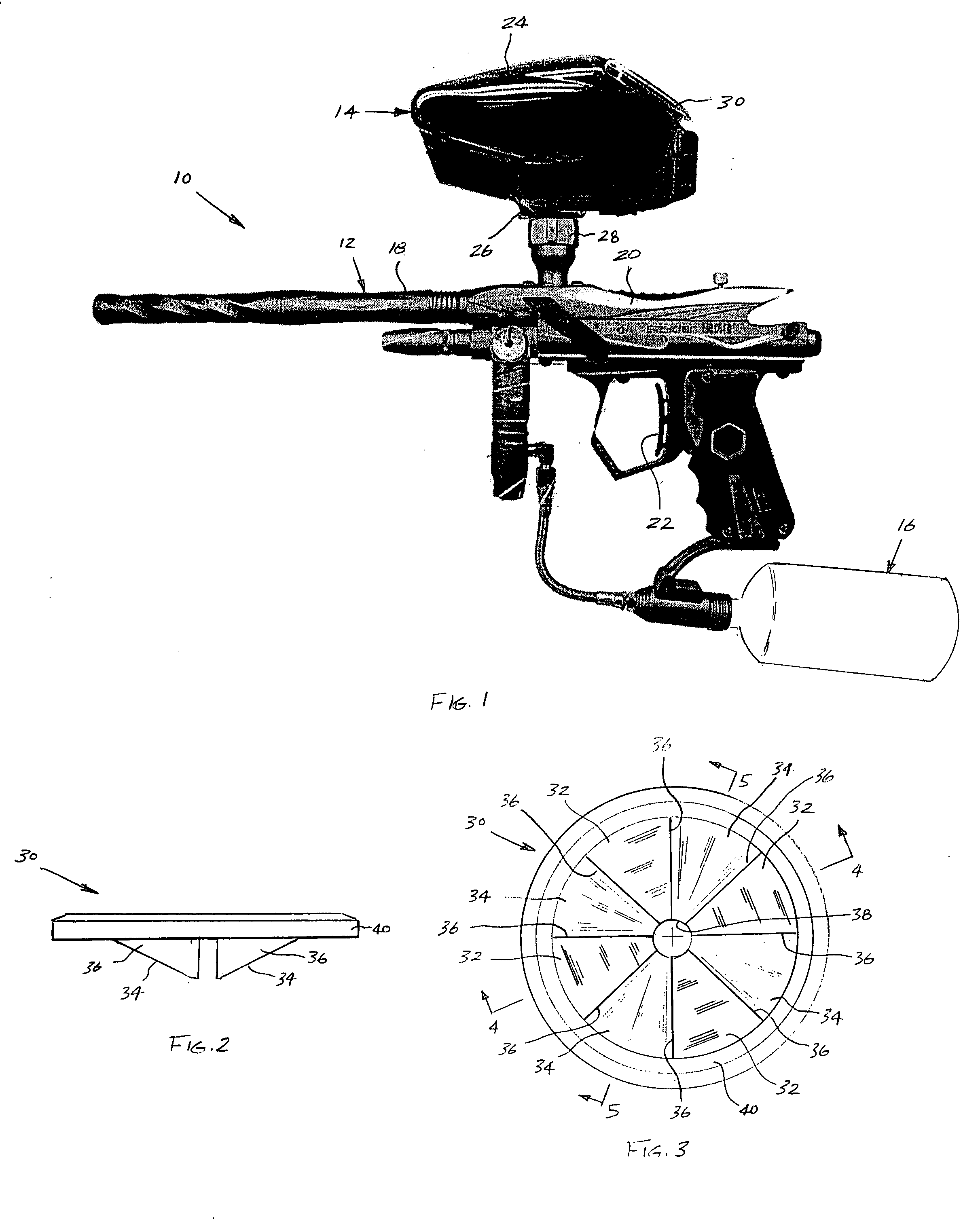

[0033]A paintball gun device 10 according to the present invention as shown in FIG. 1.

[0034]The paintball gun device 10 includes three (3) main components including a paintball gun 12, hopper device 14, and pressurized gas cylinder 16.

[0035]The paintball gun 12 includes a barrel 18 connected to a receiver 20 having a trigger 22. The paintball gun 12 can be any of a wide variety of conventional paintball guns, and the gas cylinder 16 can be any of a wide variety of conventional gas cylinders.

[0036]The hopper device 14 includes a hopper 24 provided with a connecter 26 (e.g. tubular connector to be received within receiver connector 28) and a closure 30 (e.g. specialized closure).

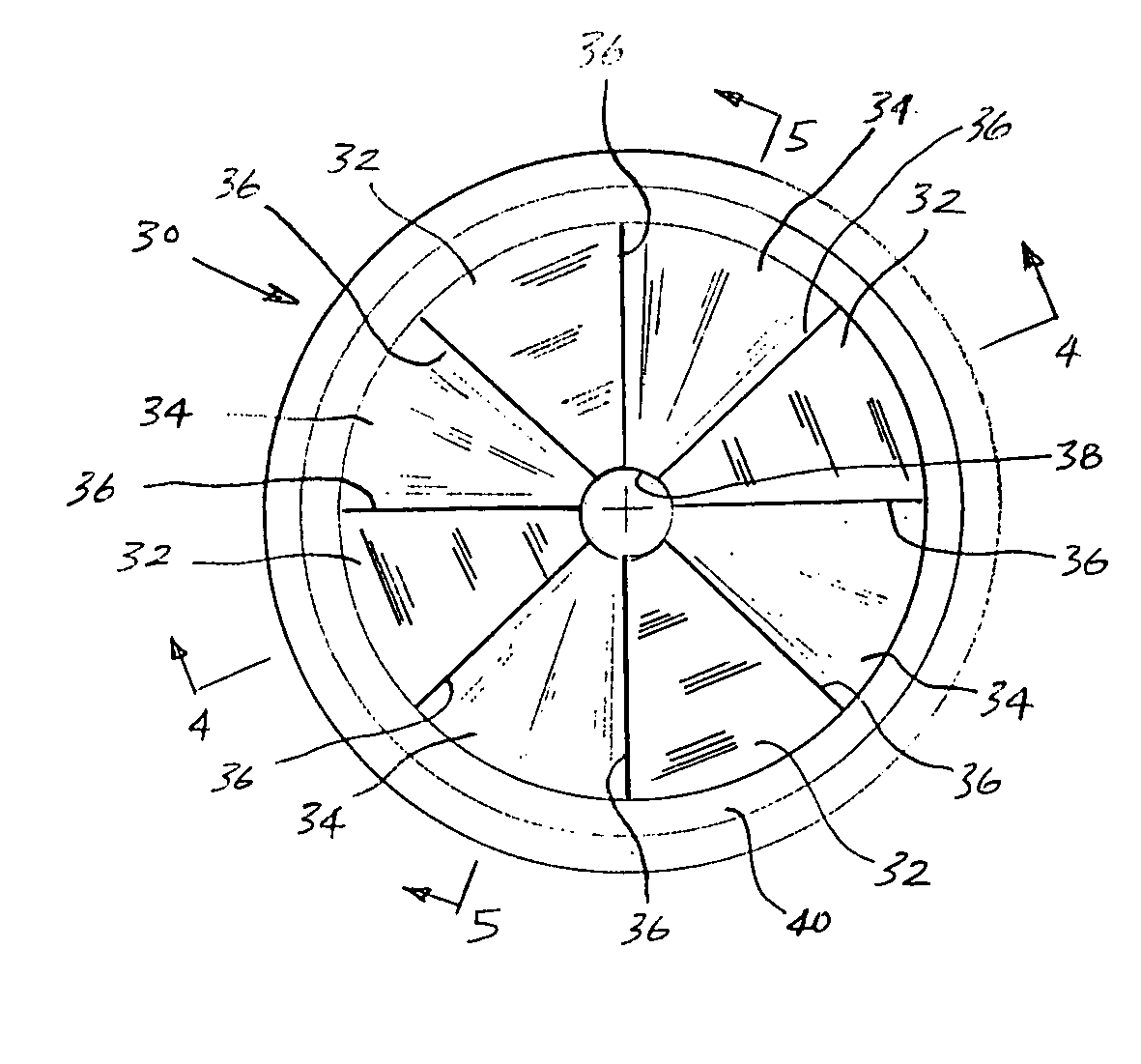

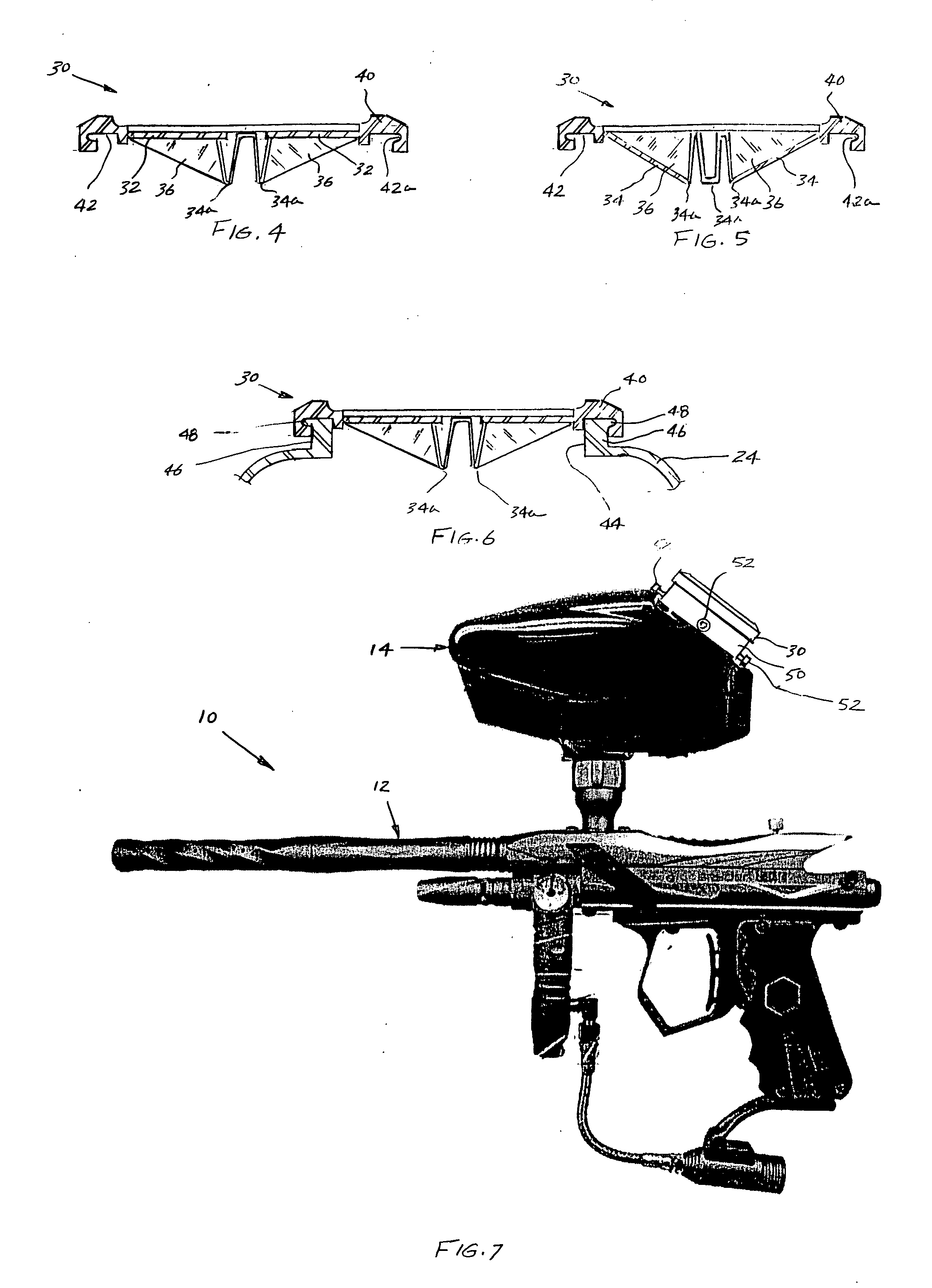

[0037]The closure 30 is shown in detail in FIGS. 2-6.

[0038]The closure 30 includes four (4) flat flap portions 32 connecting and alternating with inclined flap portions 34, as shown in FIG. 3. The flap portions 32 and 34 are connected by vertical sidewalls 36 so that the flaps 32, 34 and vertical sidewalls 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com