Distributor of a gas-liquid two phase fluid

a technology of two-phase fluid and distribution channel, which is applied in the direction of fluid circulation arrangement, refrigeration machines, lighting and heating equipment, etc., can solve the problem of extremely small energy loss (pressure loss)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

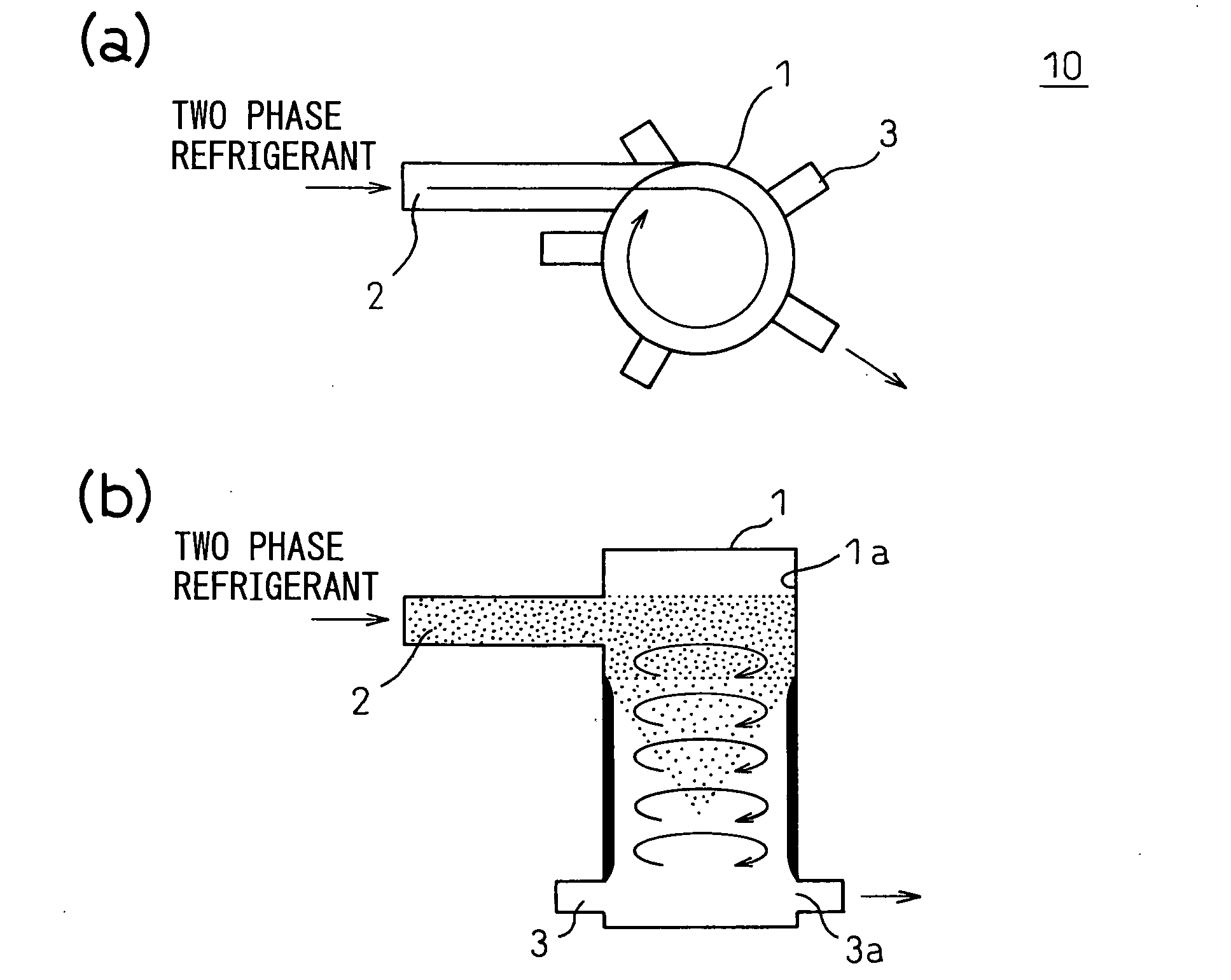

[0024]FIG. 1 shows a first embodiment of a distributor according to the present invention by schematic views. FIG. 1(a) shows a top view of the distributor, while FIG. 1(b) shows a side cross-sectional view of the distributor. In FIG. 1, reference numeral 10 is a distributor of the first embodiment, 1 is a cylindrical vessel, 2 is an inlet pipe, and 3 are distribution pipes.

[0025]The inlet pipe 2 is connected in a tangential direction with respect to the circular cross-section of the upper portion of the cylindrical vessel 1. At the lower portion of the cylindrical vessel 1, a plurality of distribution pipes 3 are connected at positions separated by equal angles in the peripheral direction and extend outward radially. That is, the plurality of distribution pipes 3 are connected to the cylindrical vessel 1 so that the intervals between them become equal distances.

[0026]Further, the gas phase two-phase refrigerant (for example, having a ratio of the liquid phase to the gas phase of ap...

second embodiment

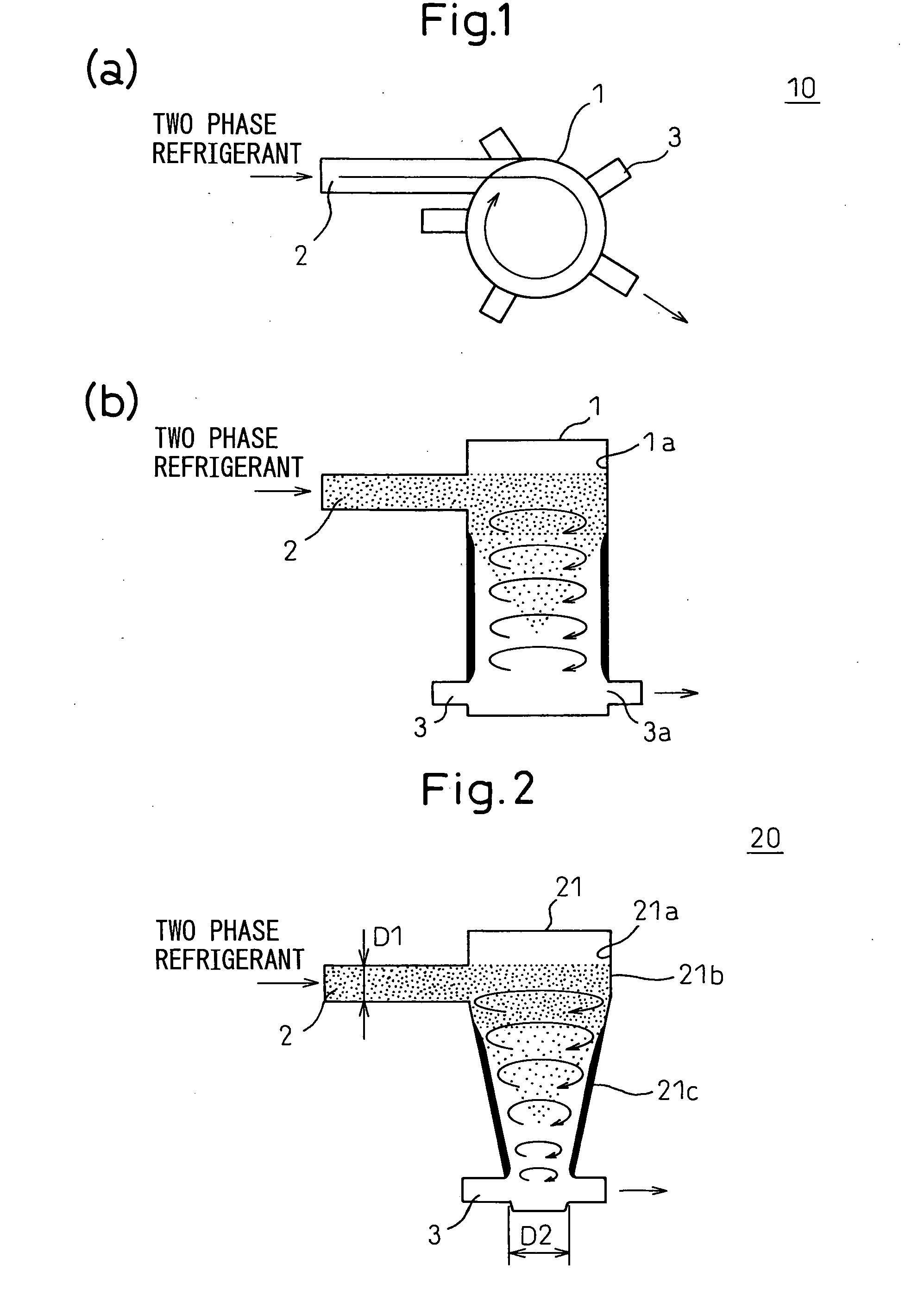

[0029]FIG. 2 shows the side cross-section of a second embodiment of the distributor according to the present invention by a schematic view. The top view is the same as FIG. 1 (a), so is omitted. The distributor of the second embodiment differs from the first embodiment in only the cylindrical vessel. Therefore, parts substantively the same as the parts of the first embodiment are assigned the same reference notations and explanations are omitted.

[0030]In FIG. 2, reference numeral 20 is the distributor of the second embodiment, while 21 is a vessel with a cylindrical upper portion 21b and an inverted conical lower portion 21c (below referred to as “the upper portion cylindrical vessel”).

[0031]The two-phase refrigerant forms a swirl flow along the inner surface 21a of the vessel 21 and flows toward the bottom of the vessel 21. At that time, the liquid film on the reverse conical surface generated by the centrifugal separation action is subjected to an upward force component by the rev...

third embodiment

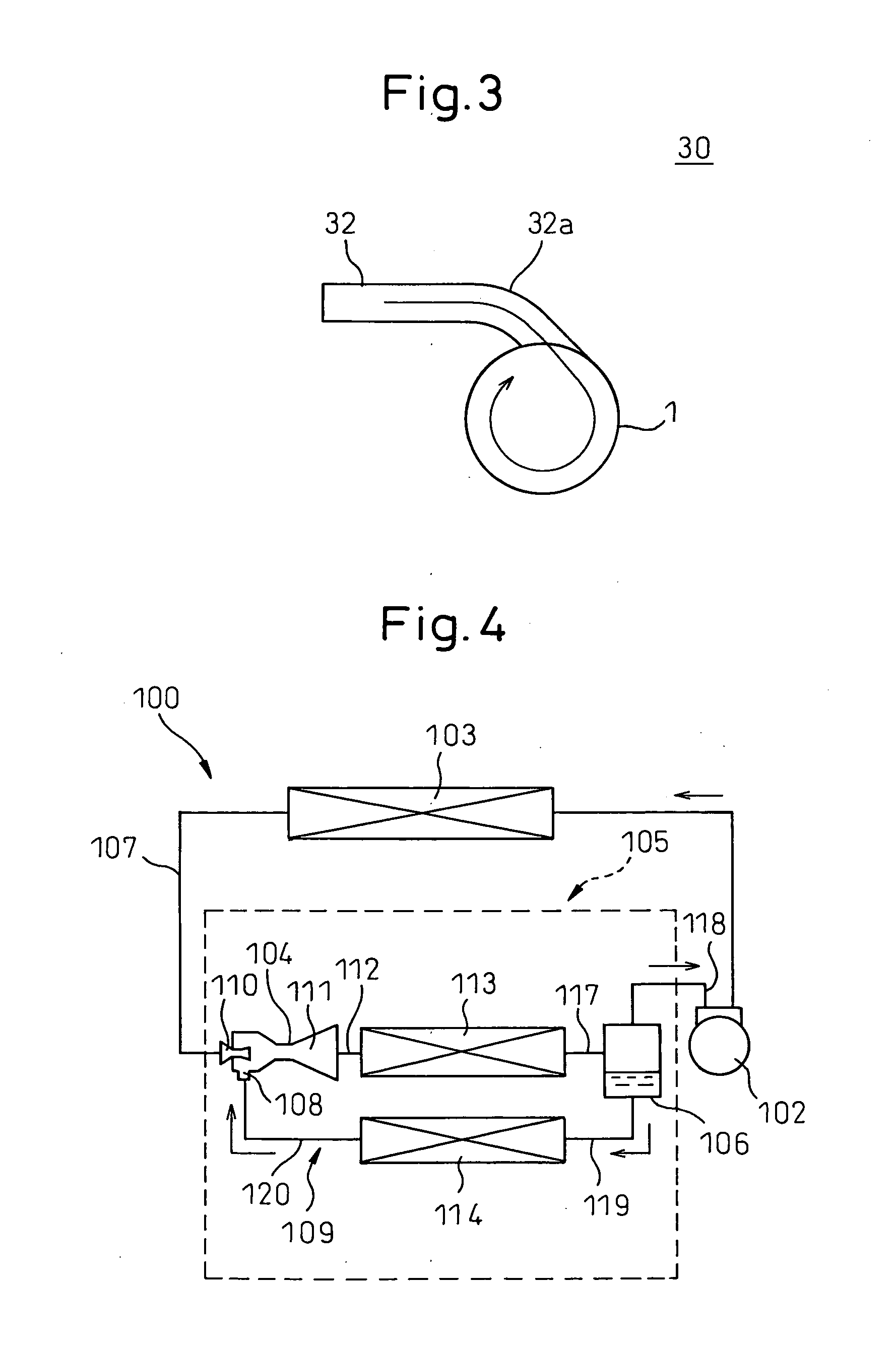

[0034]FIG. 3 shows a top view of a third embodiment of a distributor according to the present invention by schematic view. The side cross-sectional view is the same as FIG. 1(b), so is omitted. The distributor of the third embodiment differs from the first embodiment in only the inlet pipe is different. Therefore, parts substantively the same as the parts of the first embodiment are assigned the same reference notations and explanations are omitted.

[0035]In FIG. 2, reference numeral 30 is the distributor of the third embodiment, while 32 is the inlet pipe. The inlet pipe 32 has a curved portion 32a that curves just before being connected to the cylindrical vessel 1. This curve portion 32a has the function of generating a centrifugal separation action, so it becomes possible to make cylindrical vessel 1 smaller by that amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com