Ashless Controlled Release Gels

a technology of controlled release gel and ash, which is applied in the preparation of gels, lubricant compositions, fuels, etc., can solve the problem of losing its performance effectiveness upon its degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

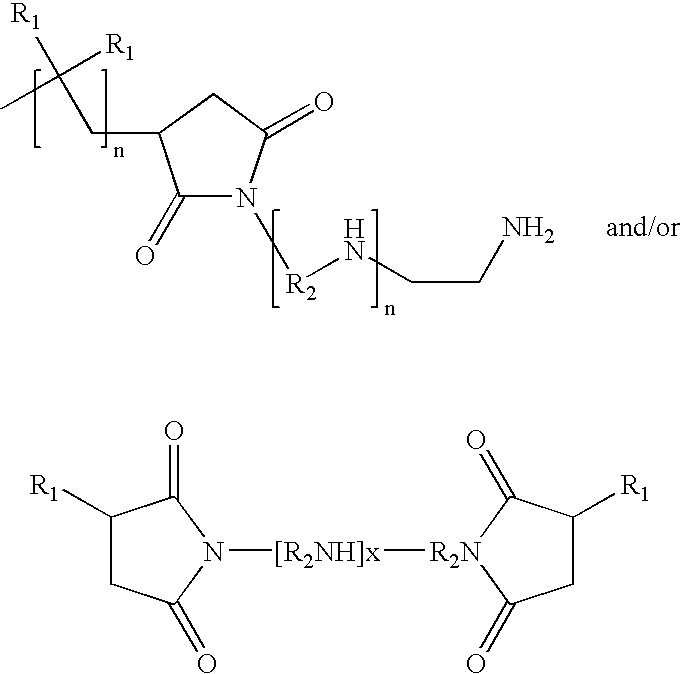

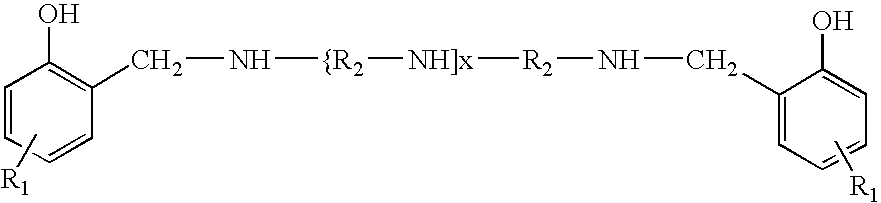

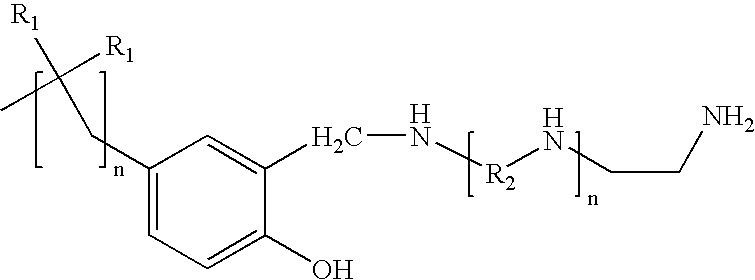

Method used

Image

Examples

specific embodiments

[0088]The controlled release of the ashless base-containing gel formulation has been demonstrated along with corresponding improvement in acid neutralization performance efficiency.

[0089]Gel 1 is formed of the following composition:

Component% wtia) Partly esterified maleic anhydride / styrene copolymer 2.4%ib) Nonyl Diphenyl amine asheldd antioxidant10.0%ii) DA PIBSA / TEPA ashless dispersant87.6%aDerived from Maleic anhydride-styrene copolymer (0.69 RSV) / C8–10 Alcohol / C12-18 Alcohol / MeSO4H(catalyst) (2.9:0.87:1.7:0.11) eq in SUAQ Oil to 60%, Total Acid Number = 23 meq KOH / g.bDerived from alykylation of diphenylamine with nonene using AIC12 catalyst, Total Base Number = 156 meq KOH / g.cDerived from 850–1600 Mn high vinylidene polyisobutylene, maleic anhydride and tetraethylene pentamine, Total Base Number = 100

[0090]The polymer and half of the antioxidant are mixed to form Component A. The dispersant and the other half of the antioxidant are mixed to form Component B. Component B was the...

example 2

Controlled Release Base Gel 1 Release—Lab Test

[0091]The Gel 1 (about 50 g) was loaded into the bottom of a 1-L beaker and about 500 g of Valvoline 10 W-30 added. The resulting mixture was heated at about 100 C and oil samples were taken at regular intervals over 13 days and the total base number measured by ASTM Test Method D2896. The results are shown in Table 1.

TABLE 1Example 2 (100% TBN release = 14 TBN added)% TheoryTest HoursTBN addedTBNTBN added00.0% 7.40411%9.02.47.519%10.12.72437%12.65.25455%15.17.76264%16.49.08074%17.810.431294%20.513.1

[0092]These results show that controlled release of ashless base can be achieved using a gel of the composition described herein.

example 3

Gel 1 Field Test

[0093]Gel 1 (about 71 g) was loaded into a cylindrical cup, with about 2 mm holes located on the top face. The container was placed at the crown end of an oil filter of the same size and fittings as a Fram PH3387A oil filter, and installed on a 2002 Pontiac Grand Prix. The car was then driven under normal stop-and-go conditions for about 500 miles, with oil samples taken at regular intervals and the total base number analyzed by ASTM D2896 and the total acid number analyzed by ATMS method D664A. The results are shown in Table 2.

TABLE 2Example 3 (100% TBN release = 2.8 TBN added)Miles0100500% TBN Release07%21%TBN-TAN5.65.86.2TBN added00.20.6

[0094]These results show that controlled release of ashless base can be achieved in a vehicle under actual driving conditions using a gel of the composition described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com