Muffler diffuser

a technology of muffler and insert, which is applied in the direction of thermometer, fuel injection apparatus, instruments, etc., can solve the problems of increased noise produced by such engines, reduced horsepower, lack of power, etc., and achieves the effect of reducing the decibels of noise produced, reducing noise and back pressure attendant to engine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

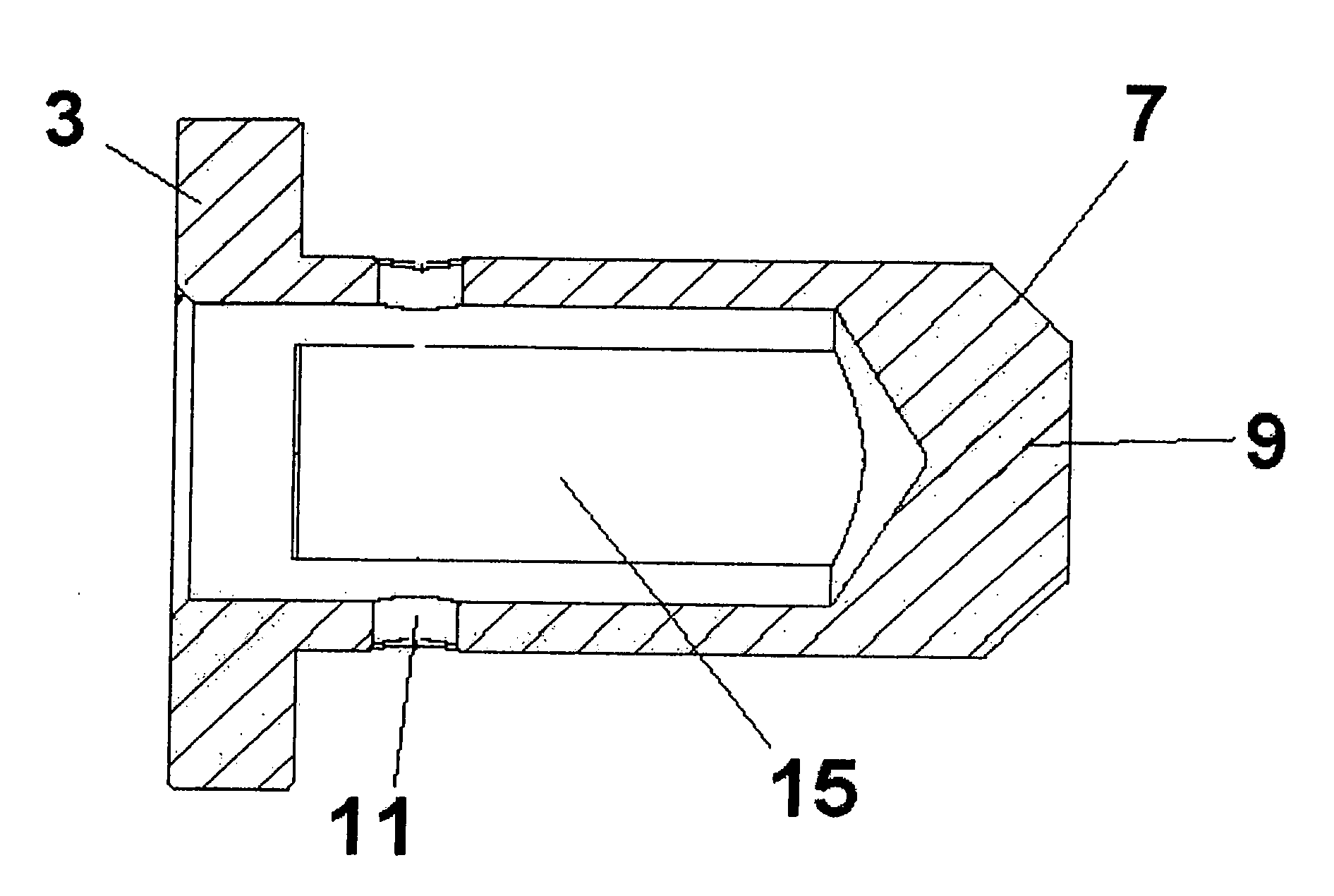

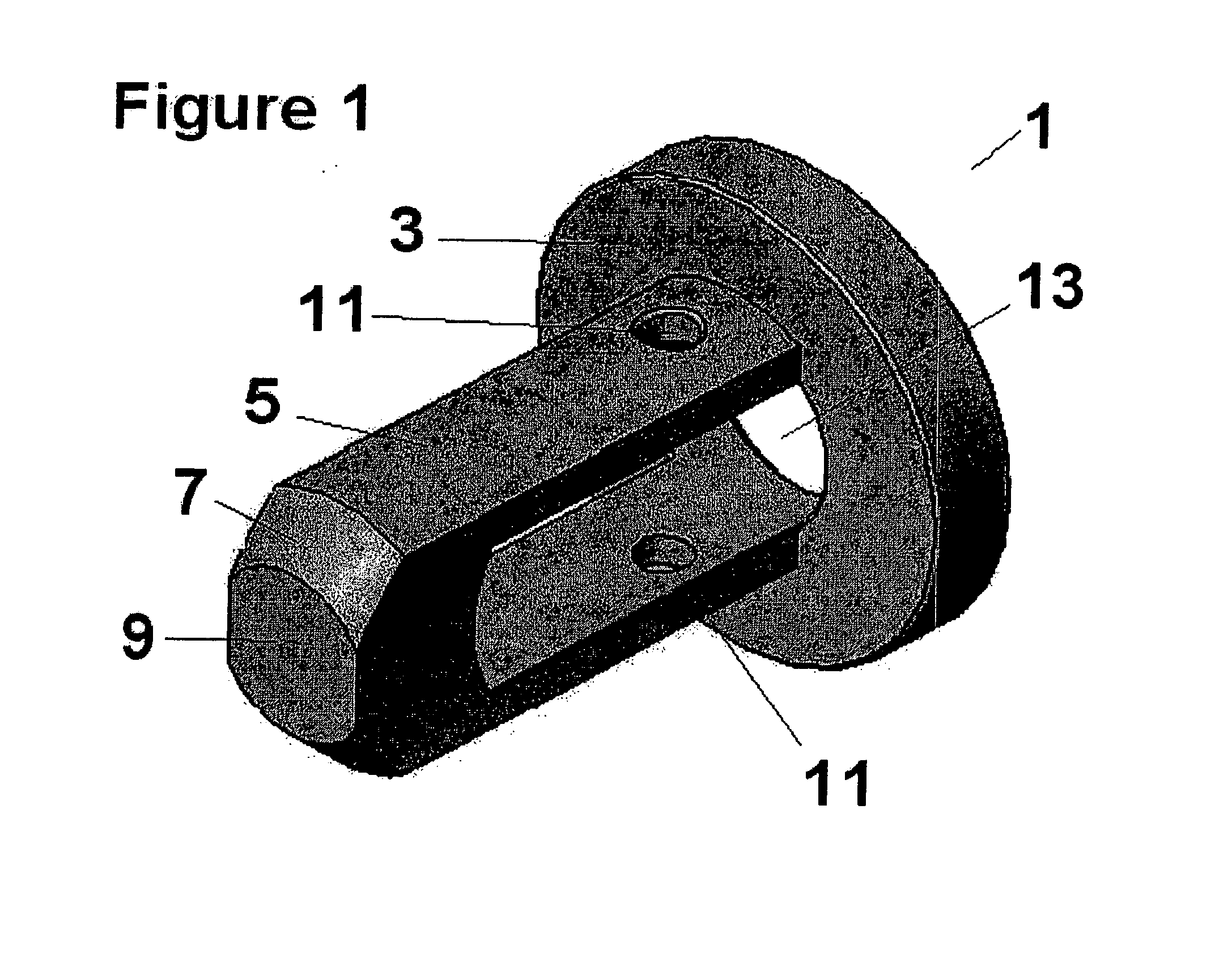

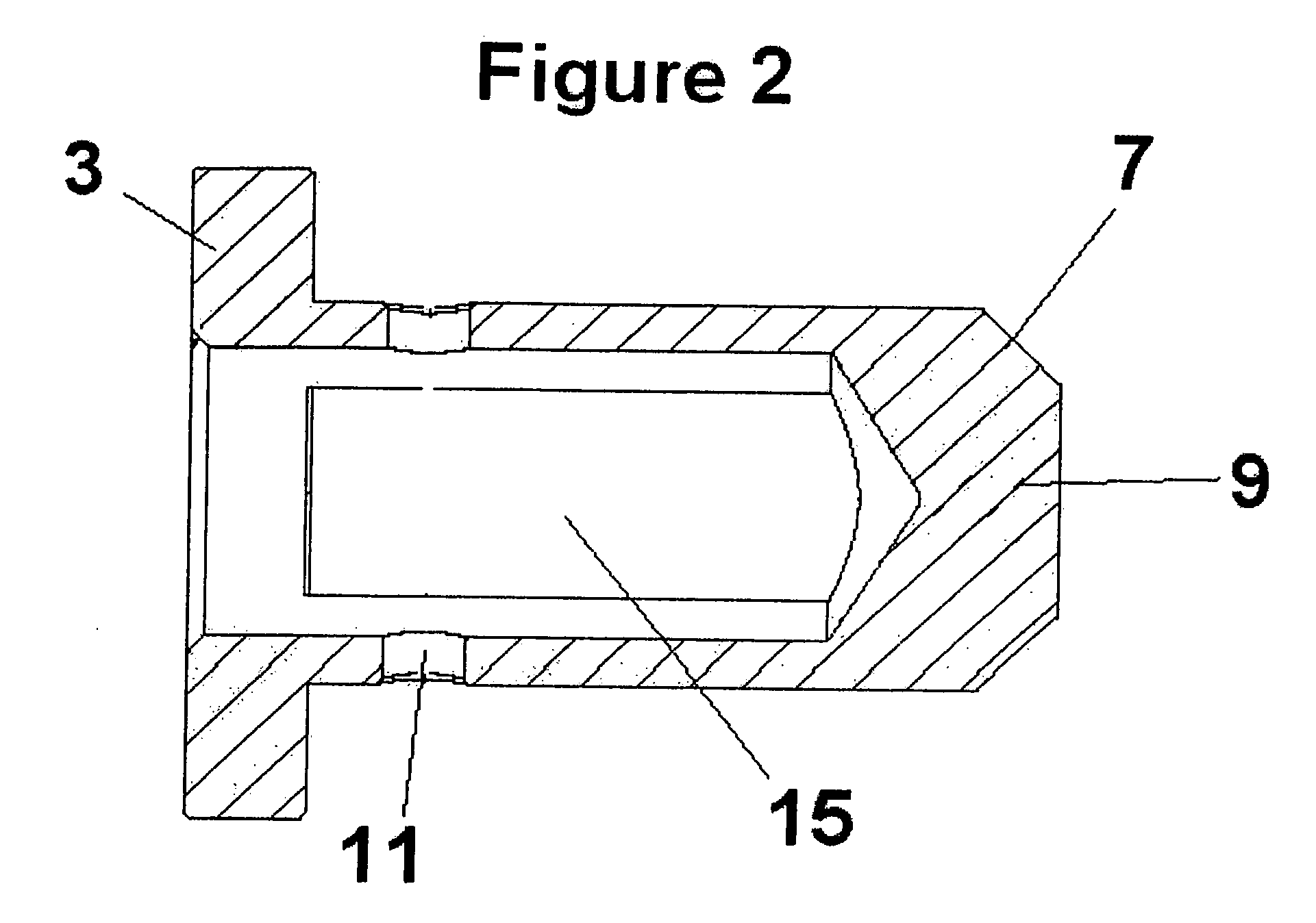

[0020]FIG. 1 broadly illustrates the muffler diffuser insert 1 of the present invention, which essentially comprises a body portion 5 integrally connected to a cap end 3, in a preferred embodiment, or which connection can be accomplished through welding or through other means which would be apparent to a worker skilled in the art. It can also be seen in FIG. 1 that the cap end is perpendicularly positioned in relation to the body portion. Preferably, the body portion 5 is elongated, and is perpendicularly positioned in relation to the cap end 3. As can be seen in FIG. 2, the body portion 5 also defines therein an opening 15, which will be described hereinafter, and possesses an insertion end 9, distally opposed from the cap end 3, which is meant for placement within a muffler. Further, the insertion end 9 further possesses sound deflection portions 7, which are positioned on either side of the outmost point of insertion end 9, such angled portions being placed, preferably, at a 45° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com