Water supply channel for evenly wetting a hybrid dry cooler

a technology of water supply channel and hybrid dry cooler, which is applied in the direction of trickle coolers, stationary conduit assemblies, lighting and heating apparatus, etc. it can solve the problems of affecting the cleaning effect, so as to eliminate the influence of surface tension and hinder cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

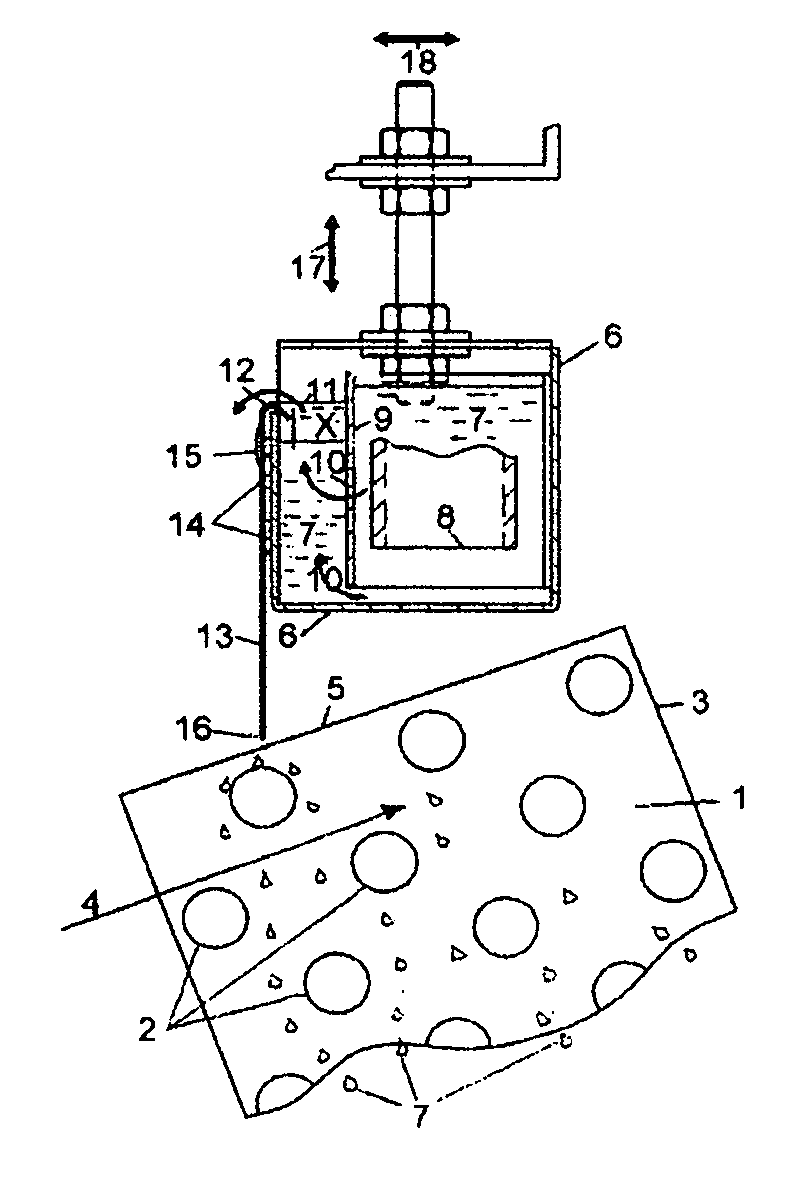

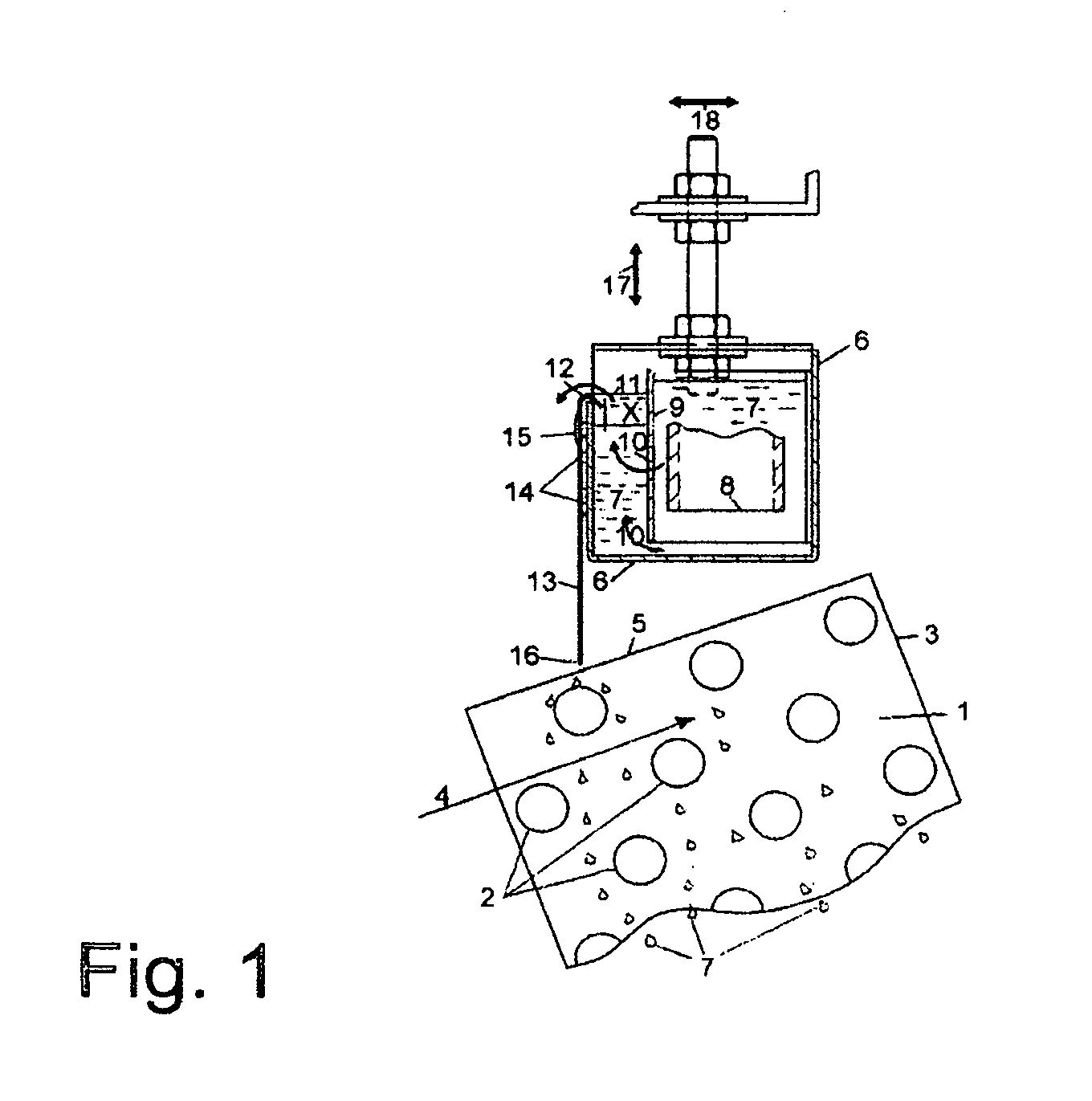

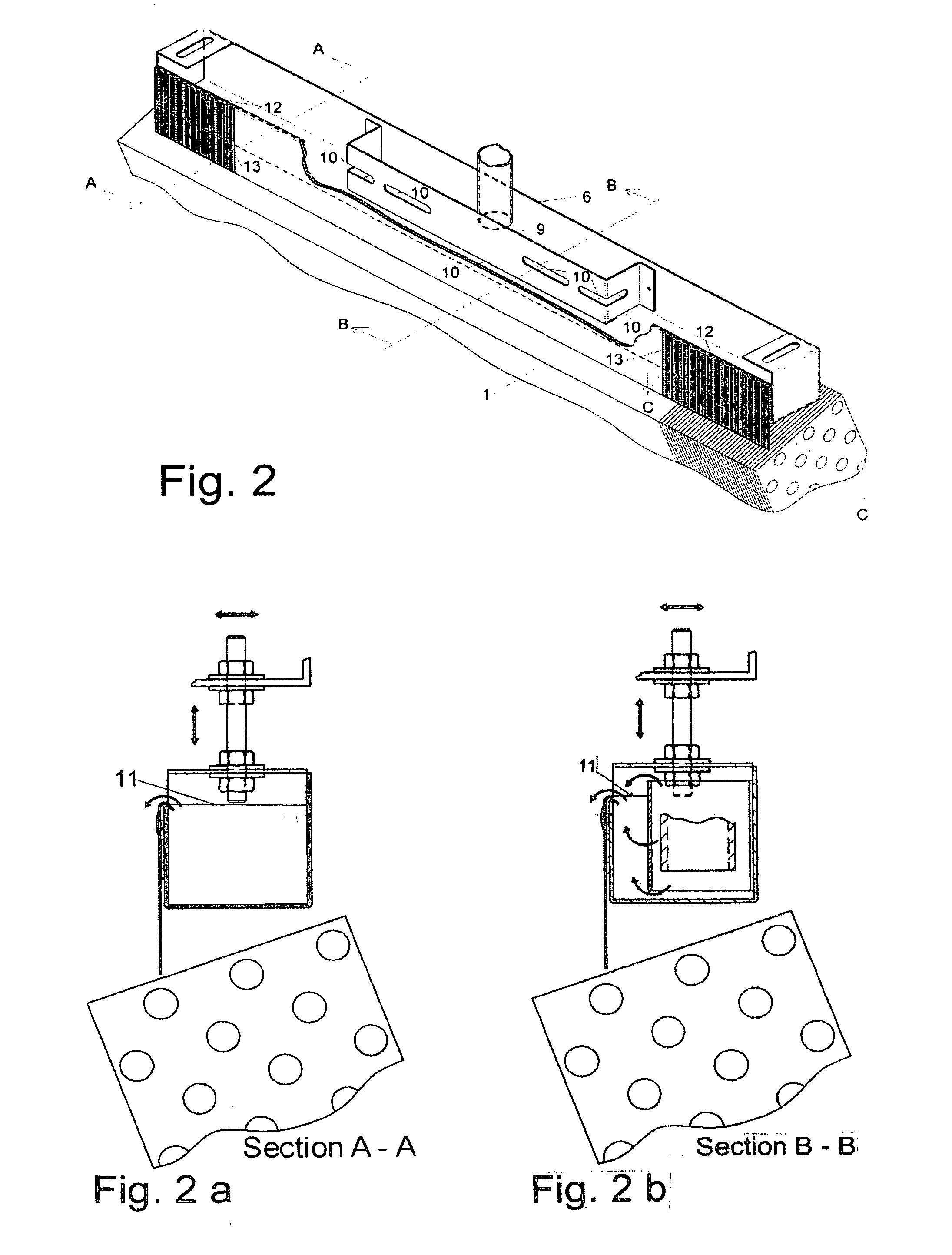

[0030]In accordance with FIG. 1 a state of the art hybrid heat exchanger 1 has several pipes 2, which run parallel to each other and which are located a distance apart from each other. The pipes 2 lie horizontal, which in FIG. 1 means vertical to the plane of the drawing. A stream of liquid is circulated through the pipes 2, whose temperature must lie above that of the ambient temperature.

[0031]On the pipes sit fins 3 along the length of the pipe which are located to increase the size of the airside heat exchange. Here it is above a compact heat exchanger whose fins 3 are drawn from several pipes 2. It could also be used where individual ribs are assigned to the individual pipes.

[0032]Above the upper face 5 of the fins 3, is located the water supply channel 6 of the wetting water 7, which is produced in large quantities, which can evaporate in the air current 4. The excess wetting water 7 is collected in a collection basin, which is not shown here, and is recycled by a pump to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com