Binder composition and method of forming foundry sand cores and molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

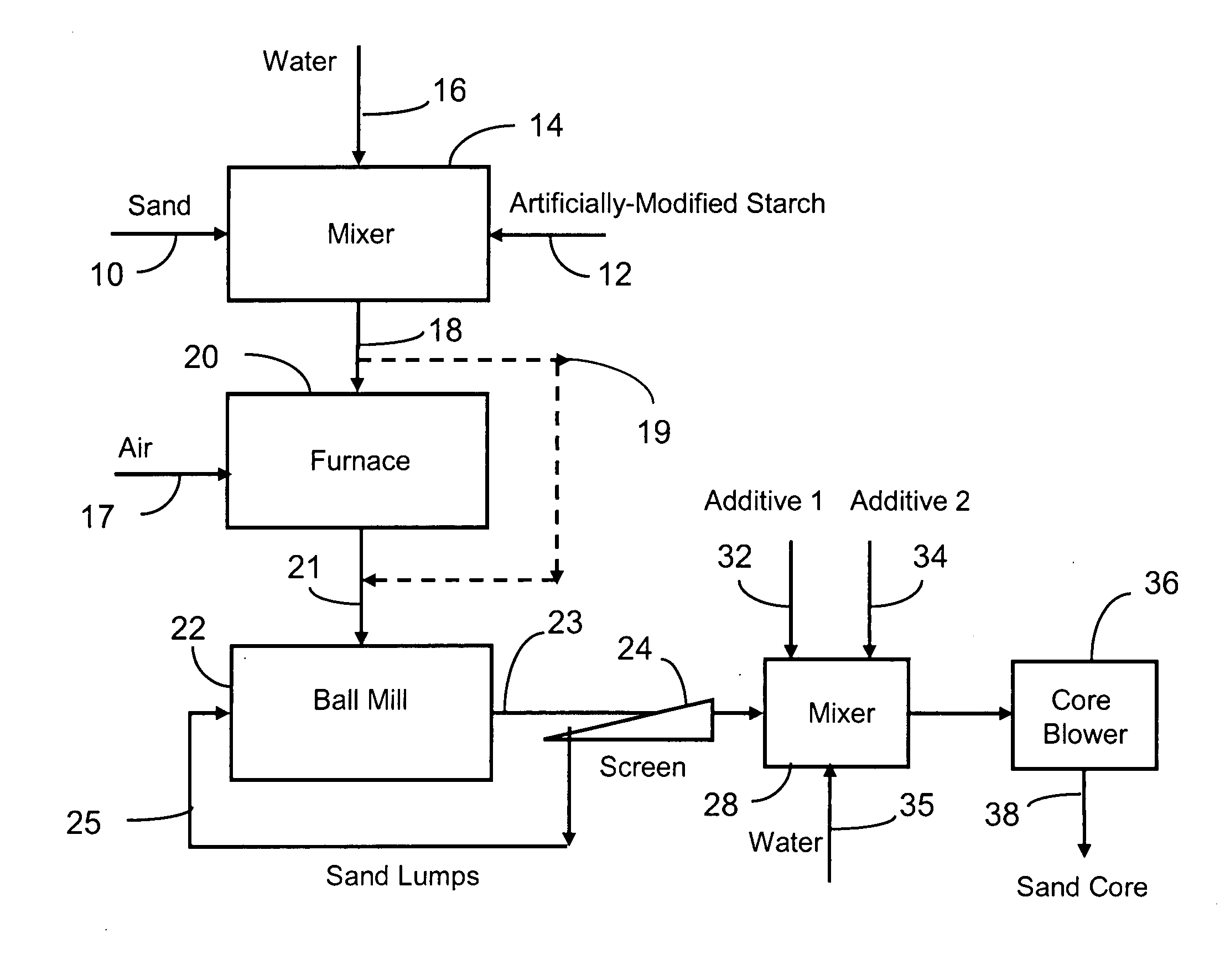

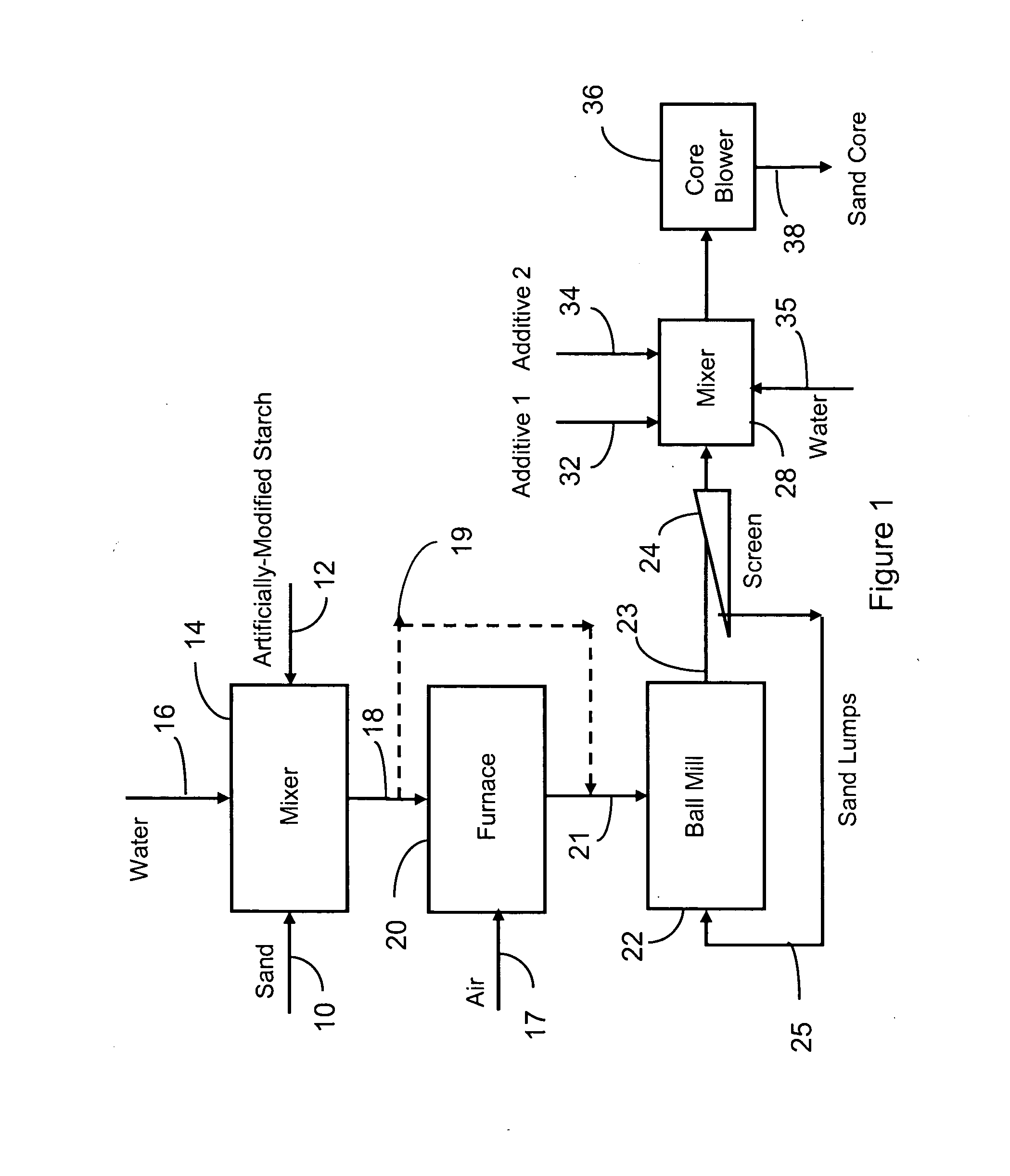

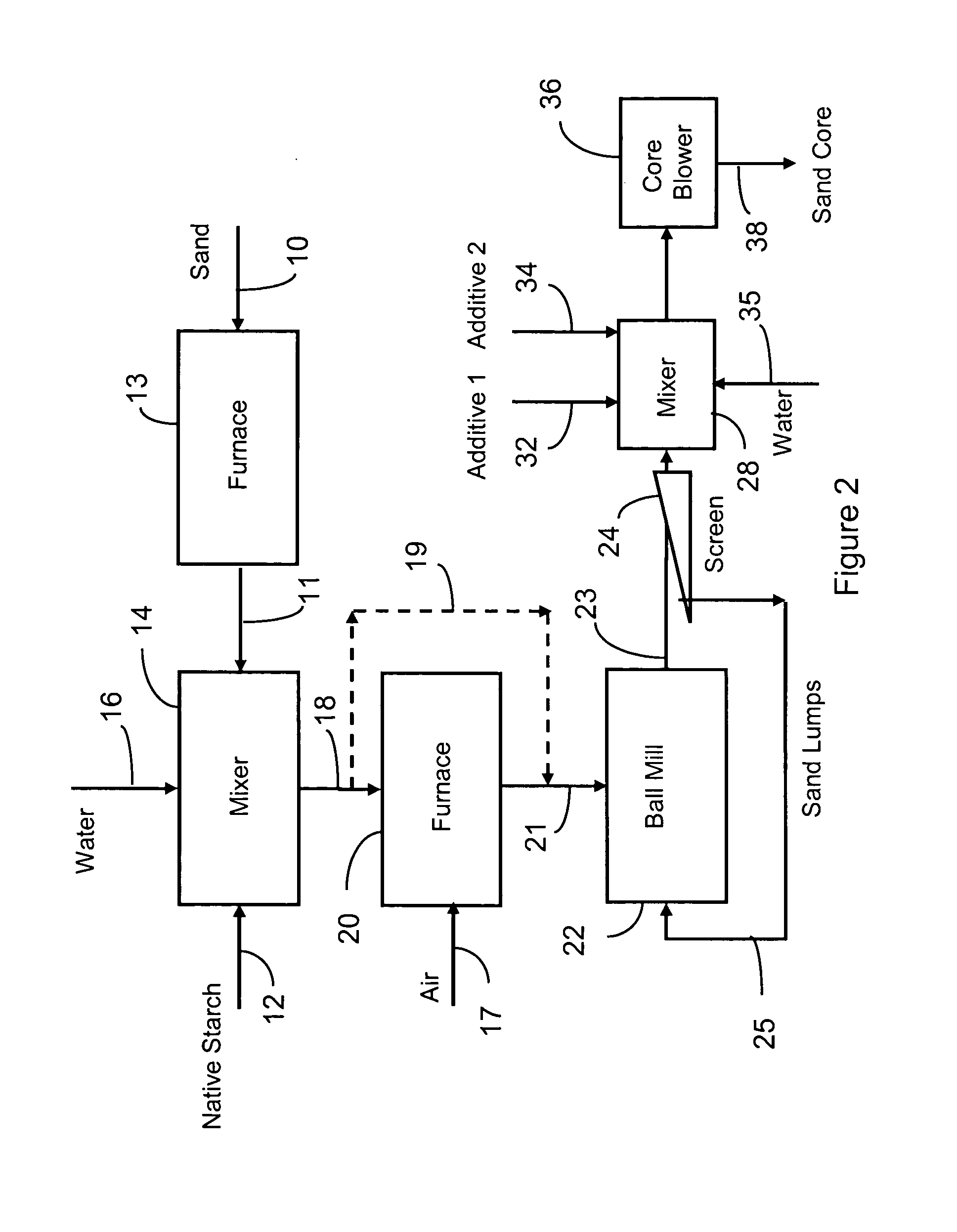

[0035]The present invention will be better understood with reference to the following detailed description of certain specific embodiments thereof.

[0036]Silica sand cores are made from sand grains bound by a suitable binder which provides a strong bond between such sand grains in such a manner and with a sufficiency to withstand the handling of the cores and the assembled molds without losing the precise dimensions and form needed for impressing the desired geometry and surface quality to the casting under the temperature and pressure of the molten metal used to form said casting.

[0037]Currently, sand cores are shaped by mixing sand and a binder, blowing the binder-sand mixture into a mold having the desired shape, and curing or hardening the binder in the mold so that the mold geometry is fixed in the cores after their removal from said mold.

[0038]There are a variety of synthetic resins used as binders as is well known in the art. According to the present invention, a water-based b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap