Damper assembly

a technology of suspension system and sprung mass, which is applied in the direction of shock absorbers, machine supports, transportation and packaging, etc., can solve the problems of disproportionate acceleration of sprung mass, easy transmission of unsprung suspension displacement by the sprung mass, and virtually lossless, and achieves low impedance and damping. , the effect of small displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

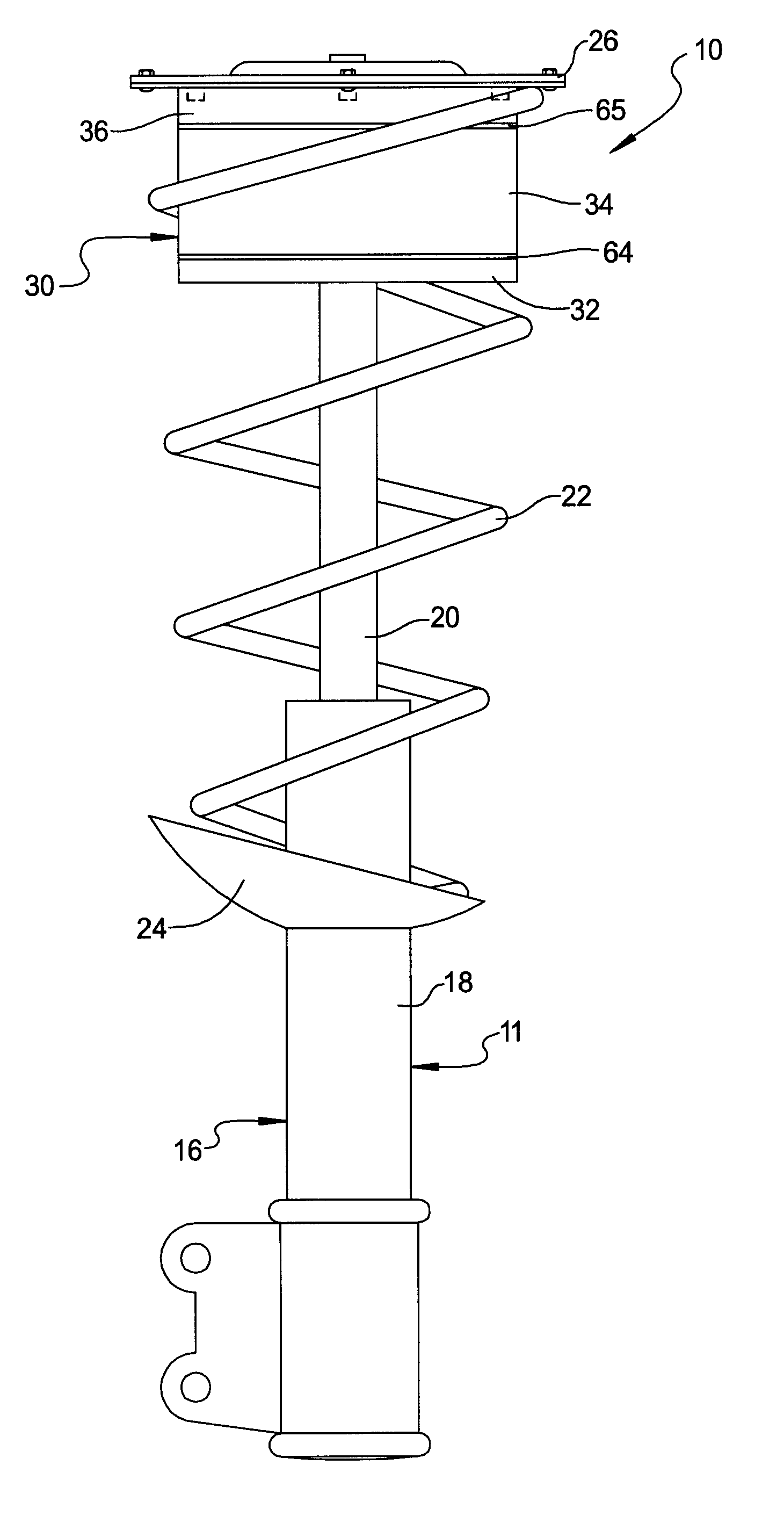

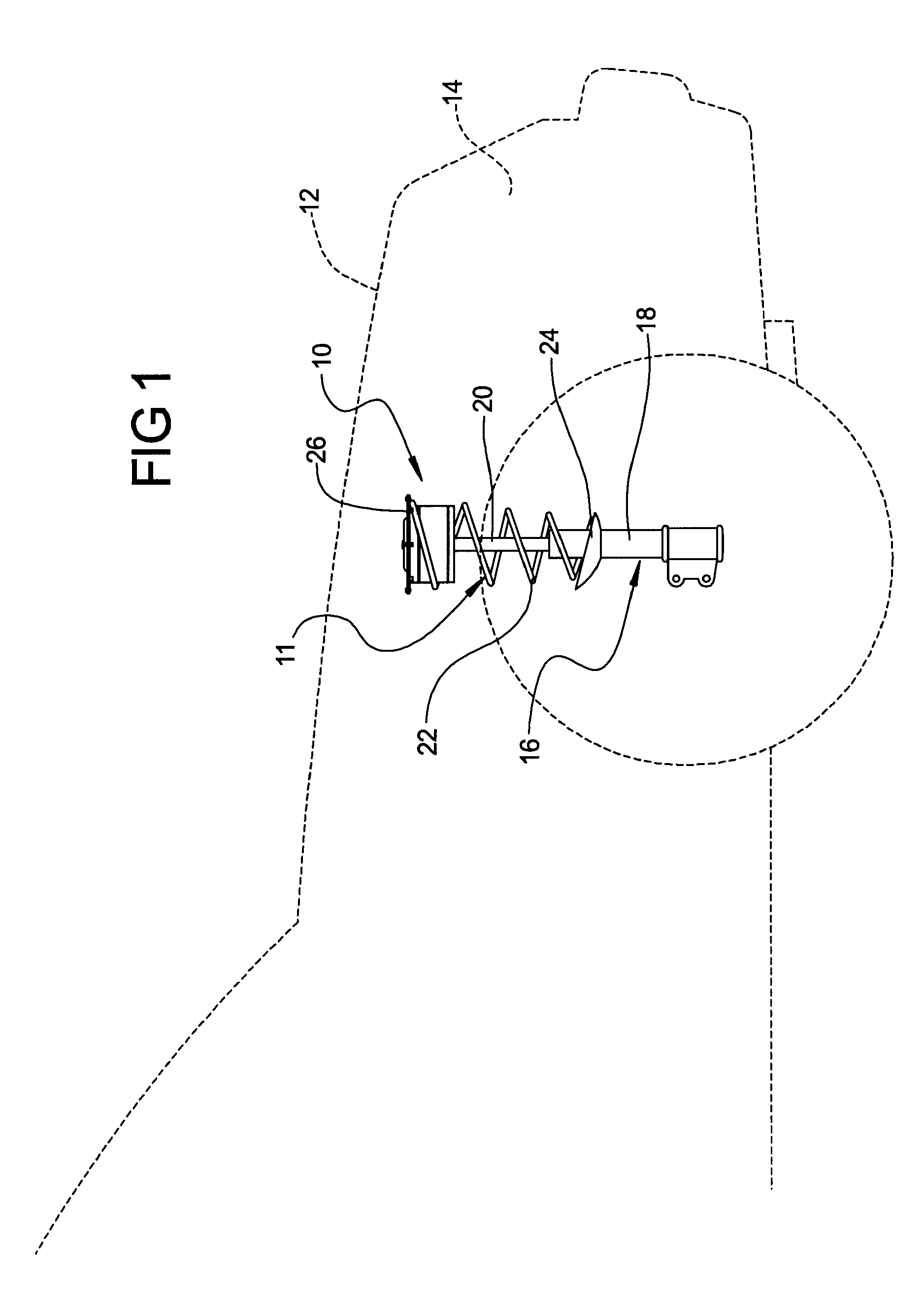

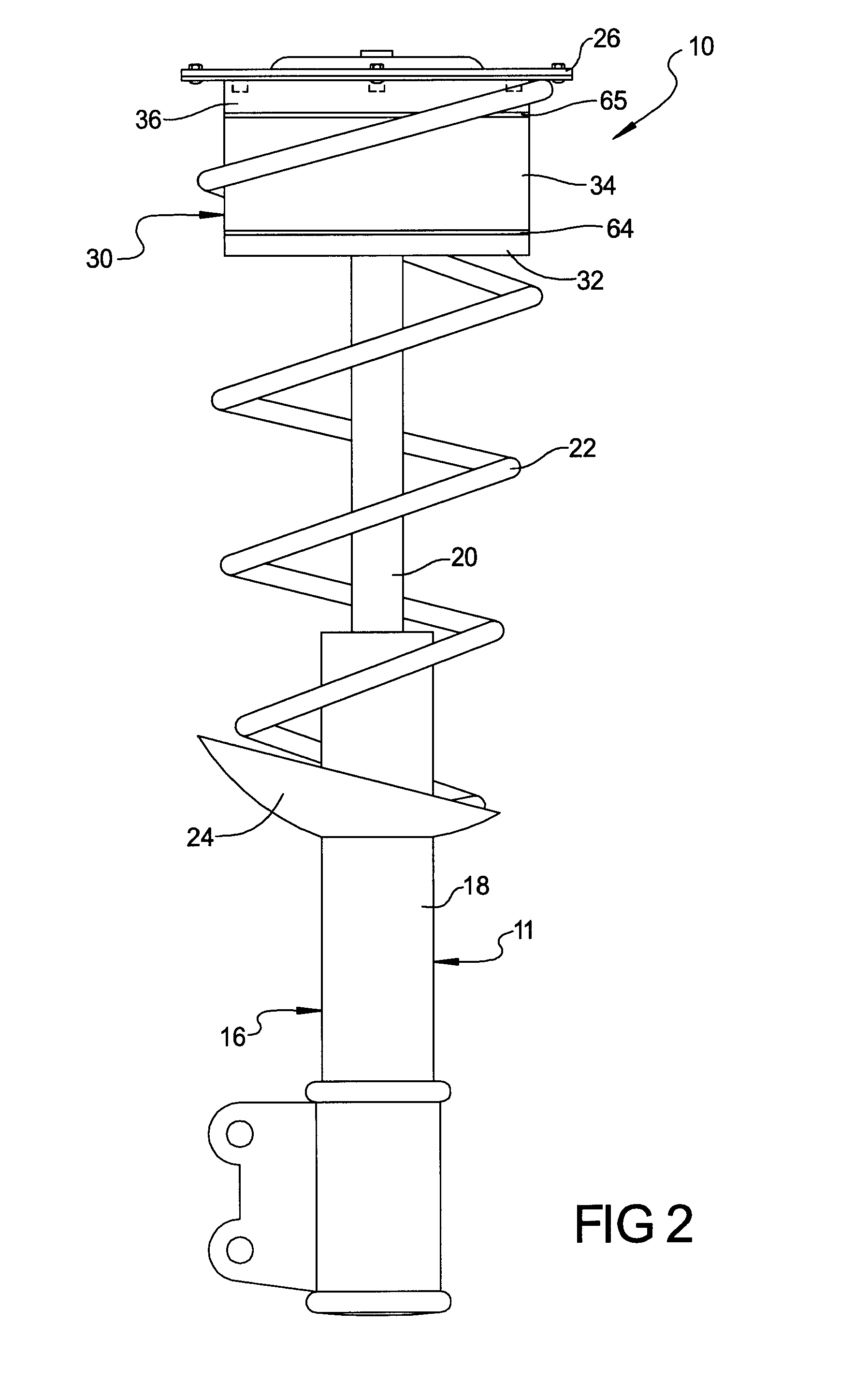

[0018]Referring to the drawings and in particular FIGS. 1 and 2, one embodiment of a damper assembly 10, according to the present invention, is shown for a suspension system, generally indicated at 11, of a vehicle 12 (partially shown). The vehicle 12 has a vehicle body 14 mounted on or integral with a vehicle chassis (not shown). It should be appreciated that the suspension system 11 is operatively connected between an unsprung portion, hereinafter referred to as unsprung mass and a sprung portion or vehicle chassis (not shown) of the vehicle 12.

[0019]The suspension system 11 includes a strut, generally indicated at 16, mounted between the unsprung mass (not shown) and the vehicle body 14 of the vehicle 12. The strut 16 includes a hydraulic cylinder 18 with an attached piston (not shown) and piston rod 20. The hydraulic cylinder 18 is attached to the vehicle chassis at its lower end by a suitable mechanism such as fasteners (not shown). The piston rod 20 slidably extends from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com