Water resistant undercast liner

a waterproof, under-cast technology, applied in knitting, textiles and papermaking, medical science, etc., can solve the problems of poor or no water resistance, padding collapses under casts, discomfort, etc., to improve drainage, improve breathability and resistance to collapse, and improve drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

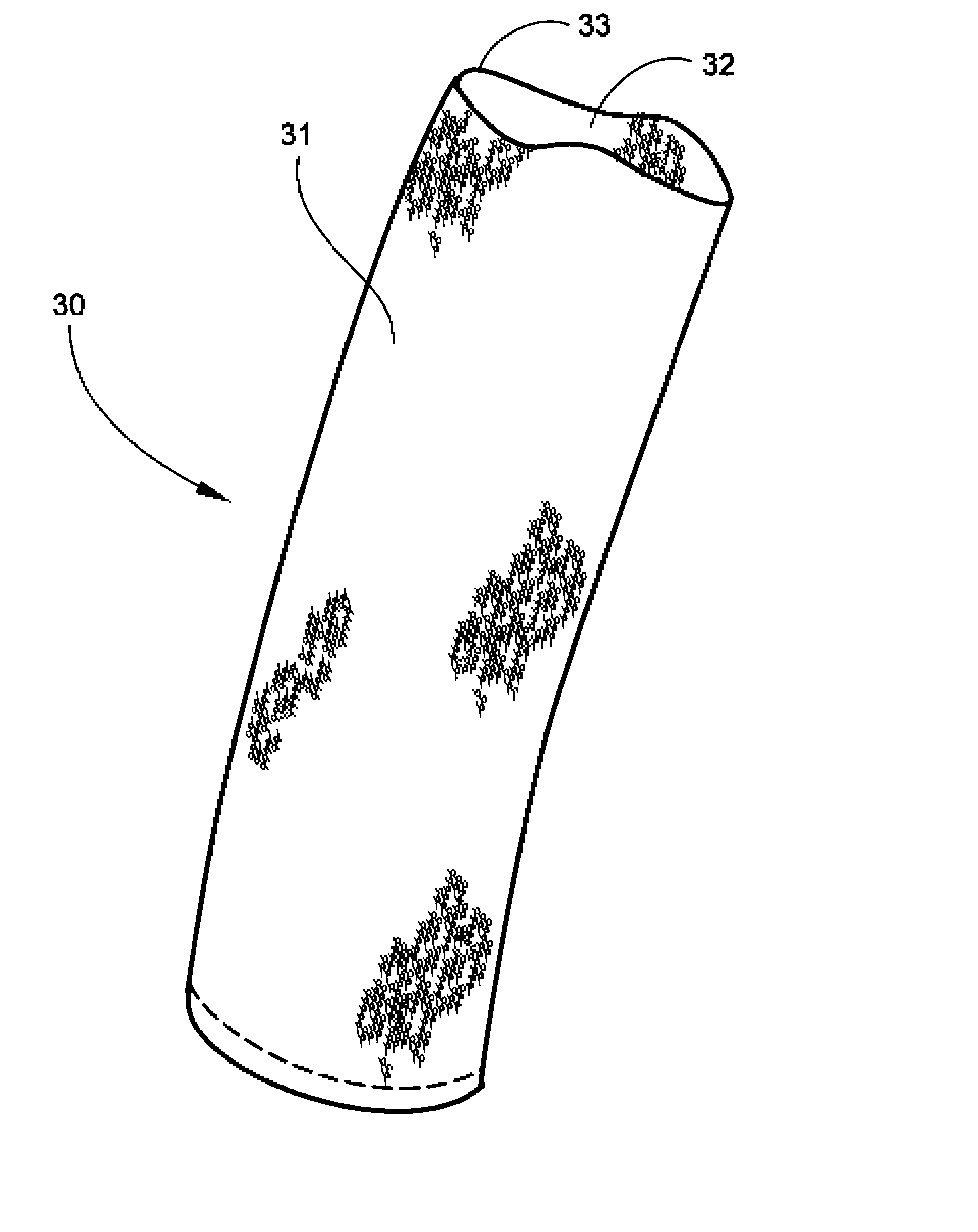

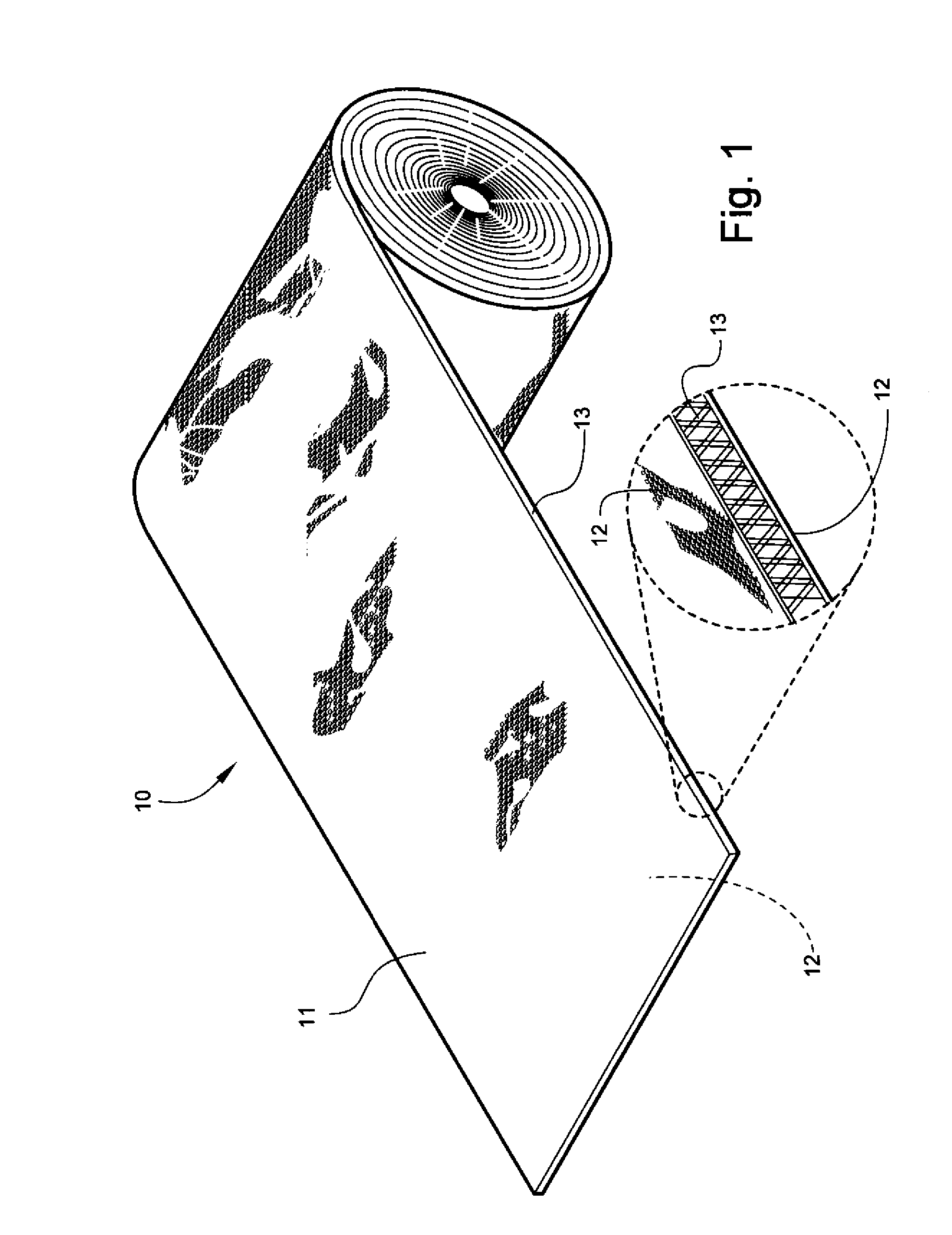

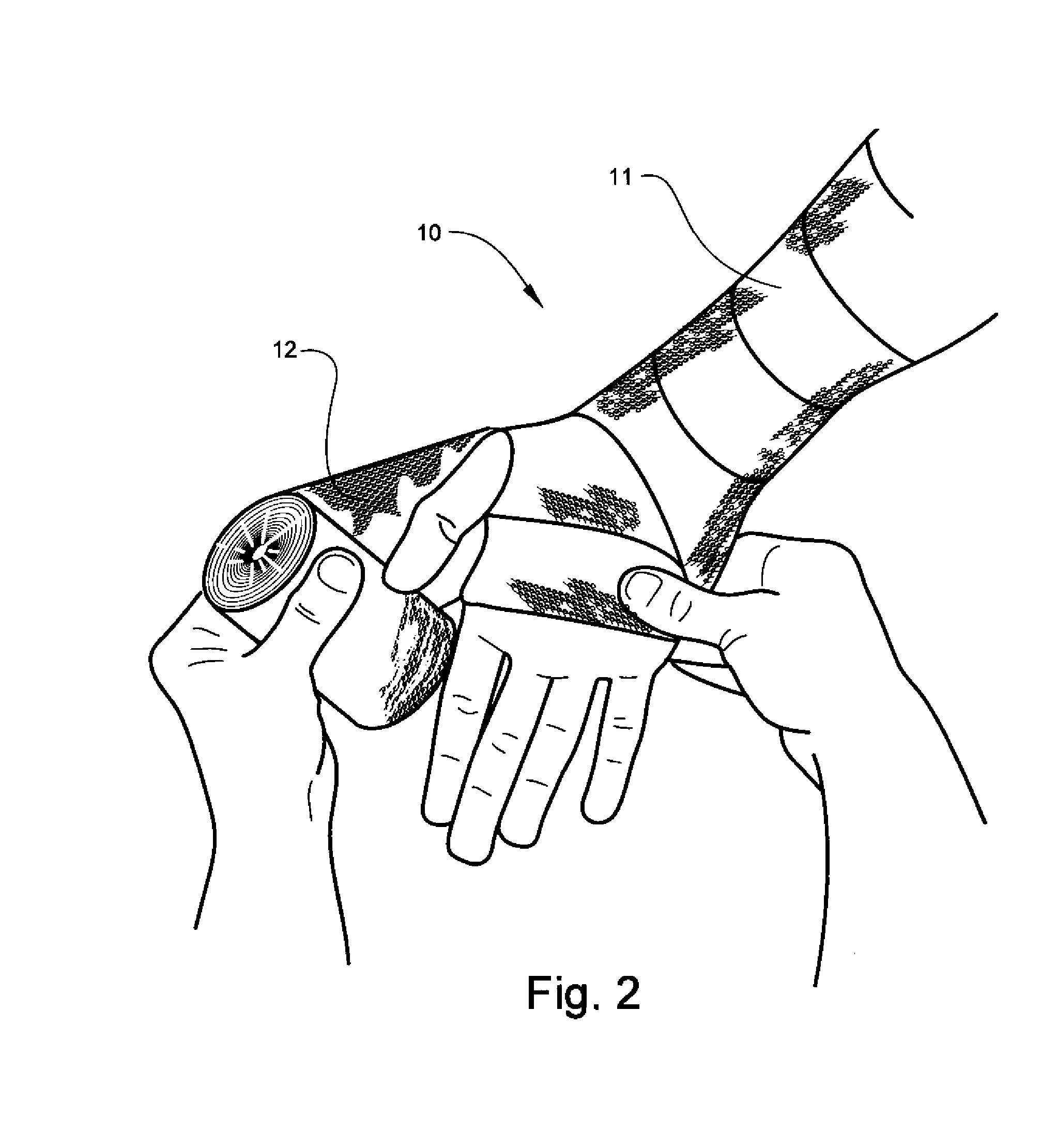

[0063] Referring now specifically to the drawings, a undercast liner according to the present invention is illustrated in FIG. 1 and shown generally at reference numeral 10. While the undercast liner 10 can be formed in any desired width or length, the undercast liner 10 shown in FIGS. 1, 2, and 3 is about 7.5 cm (about 3 in.) wide and is formed into a roll during manufacture for shipping and storage until use. The undercast liner 10 is easily applied from the roll, as shown in FIG. 2. The liner 10 includes two opposing faces 11, 12 and an intermediate spacer area 13 that both separate and interconnect the faces 11, 12, as described in further detail below. The undercast liner 10 can be formed in a tubular form or in an elongate padding form in a roll.

[0064] The liner 10 can be constructed using any suitable organic or inorganic monofilament yarn, preferably a hydrophobic / water resistant monofilament yarn such as polypropylene, polyester, polyethylene and nylon. The monofilament ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com