Method Of And Molten Metal Feeder For Continuous Casting

a continuous casting and molten metal technology, applied in the field of continuous casting of molten metals, can solve the problems of inability to achieve continuous casting, inability to meet the requirements of continuous casting, and large surface defects of irregular nature, so as to reduce the incidence of oxide incorporation, improve the continuous casting of molten metal, and reduce the surface defects of cast articles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

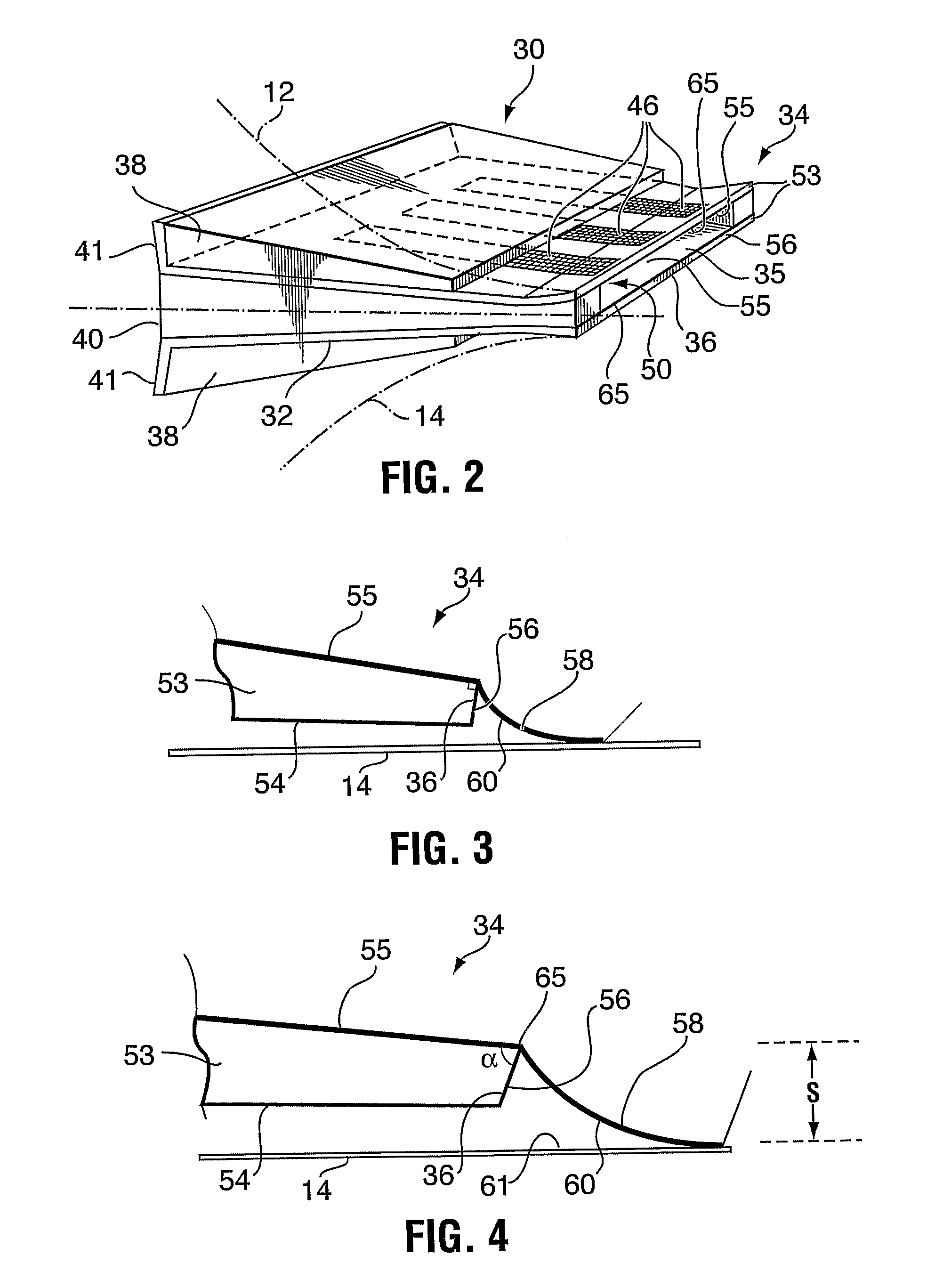

[0050] The effects of different feeder tip angles were investigated on a single mold plane (water cooled) utilizing an open-topped box with a sliding bottom, to simulate the metal flow conditions from a stationary feeder tip onto a moving water cooled belt. The apparatus employed is shown schematically in FIG. 5 (plan view) and FIG. 6 (vertical longitudinal cross-section).

[0051] The metal was poured into a box 70 and a bottom plate 71 was pulled horizontally at predetermined speeds and molten metal temperatures, allowing the metal 75 to flow from an end 72 of the moving bottom plate onto a sheet steel mold 73, where it solidified progressively towards the moving bottom plate. The moving bottom plate (forming a thin slide) was made of the same material as the feeder tips used for continuous casting, and the right hand end was changed in geometry as shown in FIGS. 7A to 7D to study the effects of such changes on the solidified metal, such as meniscus break lines and other ingot surfa...

example 2

[0052] A series of casts were performed in a pilot scale belt caster using metal delivery nozzles having various cut-back angles. Casts were made on copper belts using aluminum alloy AA5754 cast 10 mm thick cast at a speed of 8 to 10 meters / minute.

[0053] The surface of the as cast strip was observed and photographed. The results are shown in FIGS. 8 to 12 and are summarized in Table 1 below.

TABLE 1Cut back angleFigure NumberObservation93 degrees8Severe oxide banding or foldsirregularly spaced about 30 mmapart88 degrees9Oxide banding or folds irregularlyspaced about 30 mm apart78 degrees10Regular fine banding about 1 mmspacing48 degrees11Regular fine banding about 1 mmspacing33 degrees12Regular fine banding about 1 mmspacing

[0054] Cut back angles of 93 and 88 degrees are outside the range of angles of the invention and the sheet cast using tips at such angles exhibit unacceptable oxide folds or banding. A spacing of 30 mm, typical of such bands, corresponds to a frequency of about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| included angle | aaaaa | aaaaa |

| included angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com