Method of Producing a Carpet or Rug, and a Carpet or Rug Produced by Such Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

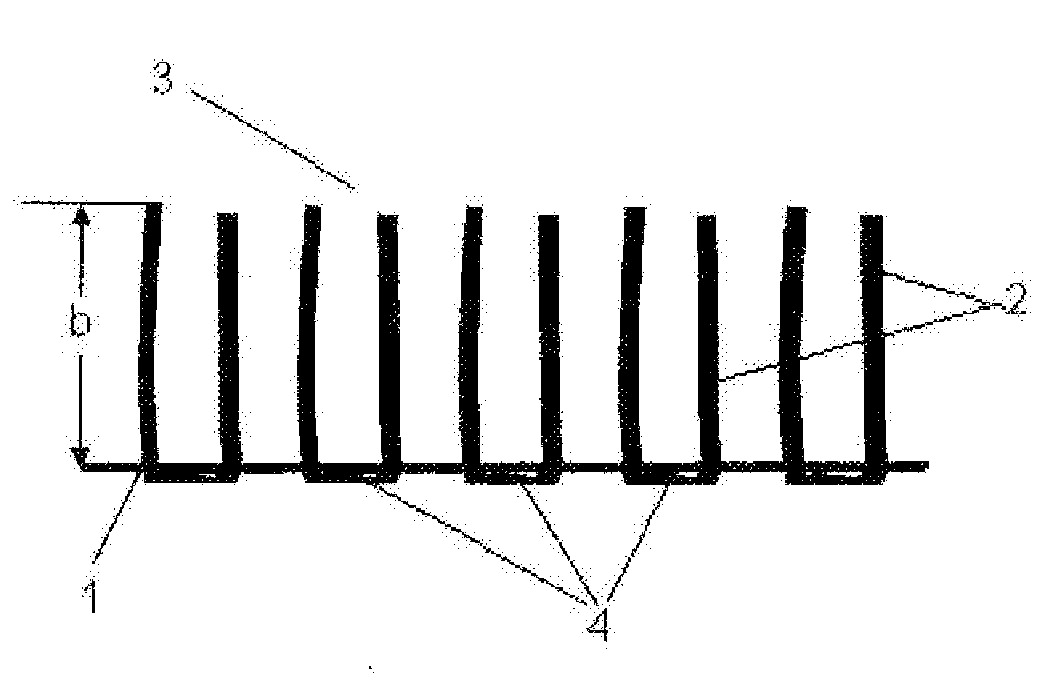

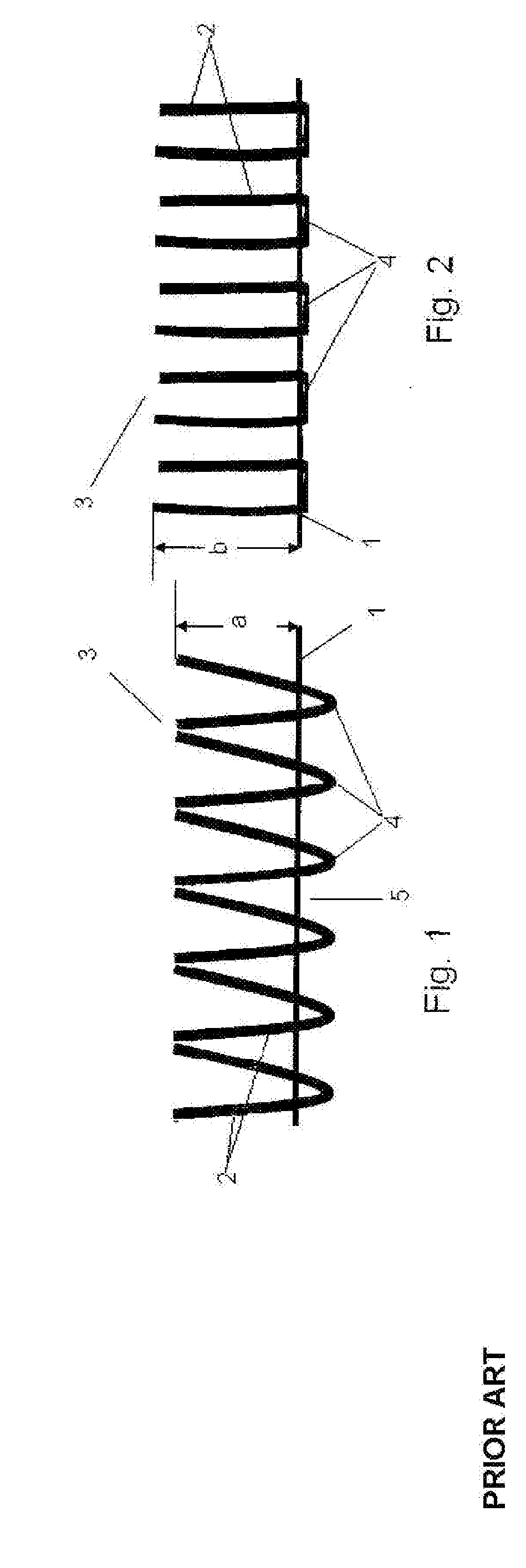

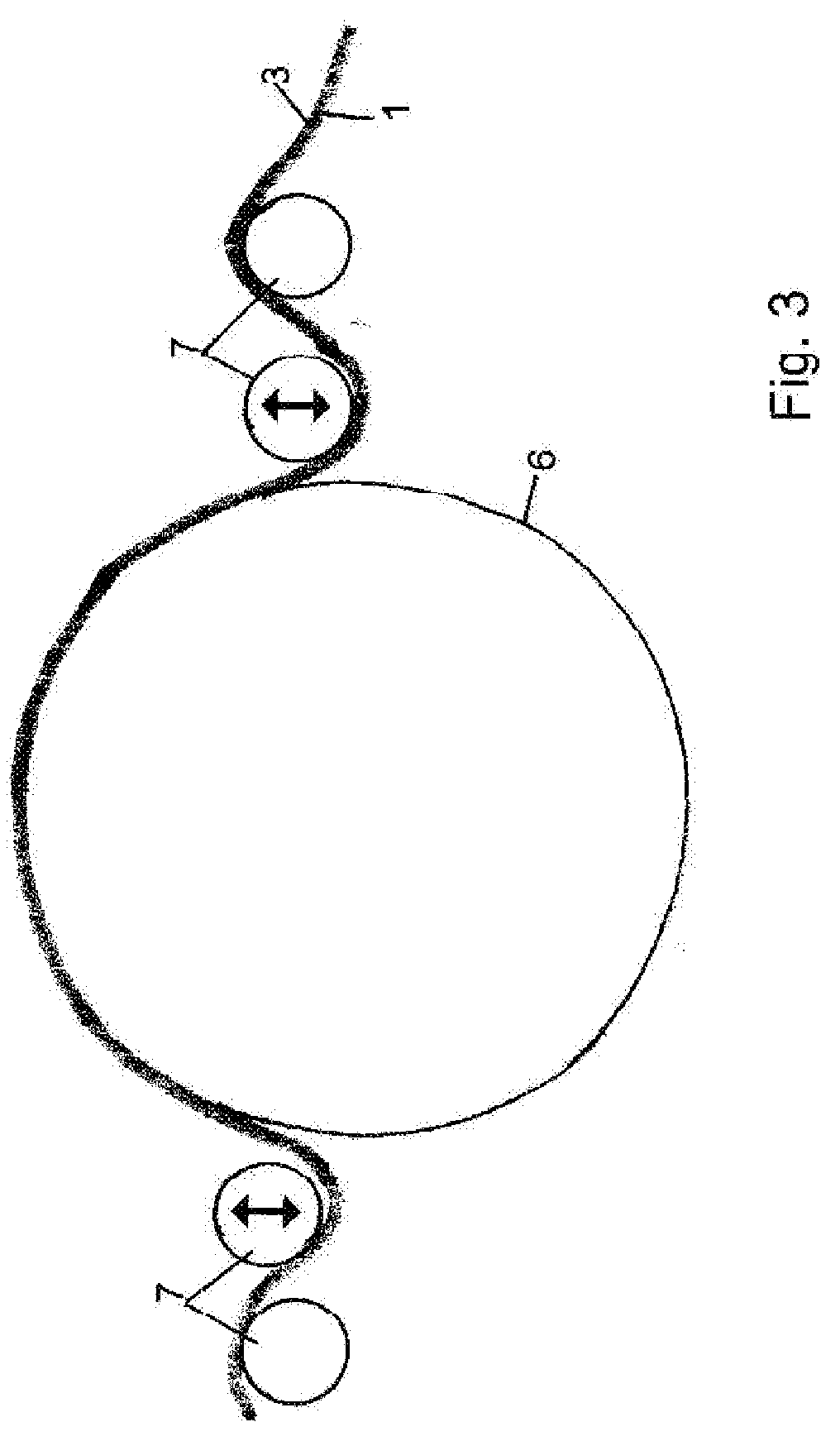

[0014]Referring now to the drawings in detail, a carpet or rug manufactured using the tufting process is comprised of a woven base or spun fabric, a tuft support or substrate 1, into which are tufted pile threads or filaments 2 on a multiple needle machine. Above the tuft substrate 1, the pile threads 2 form a pile layer 3 having the height a in FIG. 1. The loops 4 of the pile threads 2 are pierced through the tuft substrate 1 and must be held securely in place.

[0015]Pursuant to the state of the art of FIG. 1, the pile binding is effected in that a layer 5 of a liquid adhesive is applied onto the underside of the tuft substrate 1, together with the pierced-through loops 4 of the pile threads 2; the layer 5 covers the tuft substrate 1 and encases the pierced-through loops 4 of the pile threads 2. To cure the adhesive, the coated carpet is heated, whereby the volatile material present in the adhesive evaporates. This thermal treatment involves an increased expenditure of energy and ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com