Apparatus of driving plasma display panel

a technology of plasma display panel and apparatus, which is applied in the direction of static indicating device, casing/cabinet/drawer details, instruments, etc., can solve the problems of generating strong discharge entailing an undesired shape of brightness point, erroneous brightness point fire, etc., and achieve accurate temperature detection and stab driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawing.

[0046]Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to FIGS. 5 to 8.

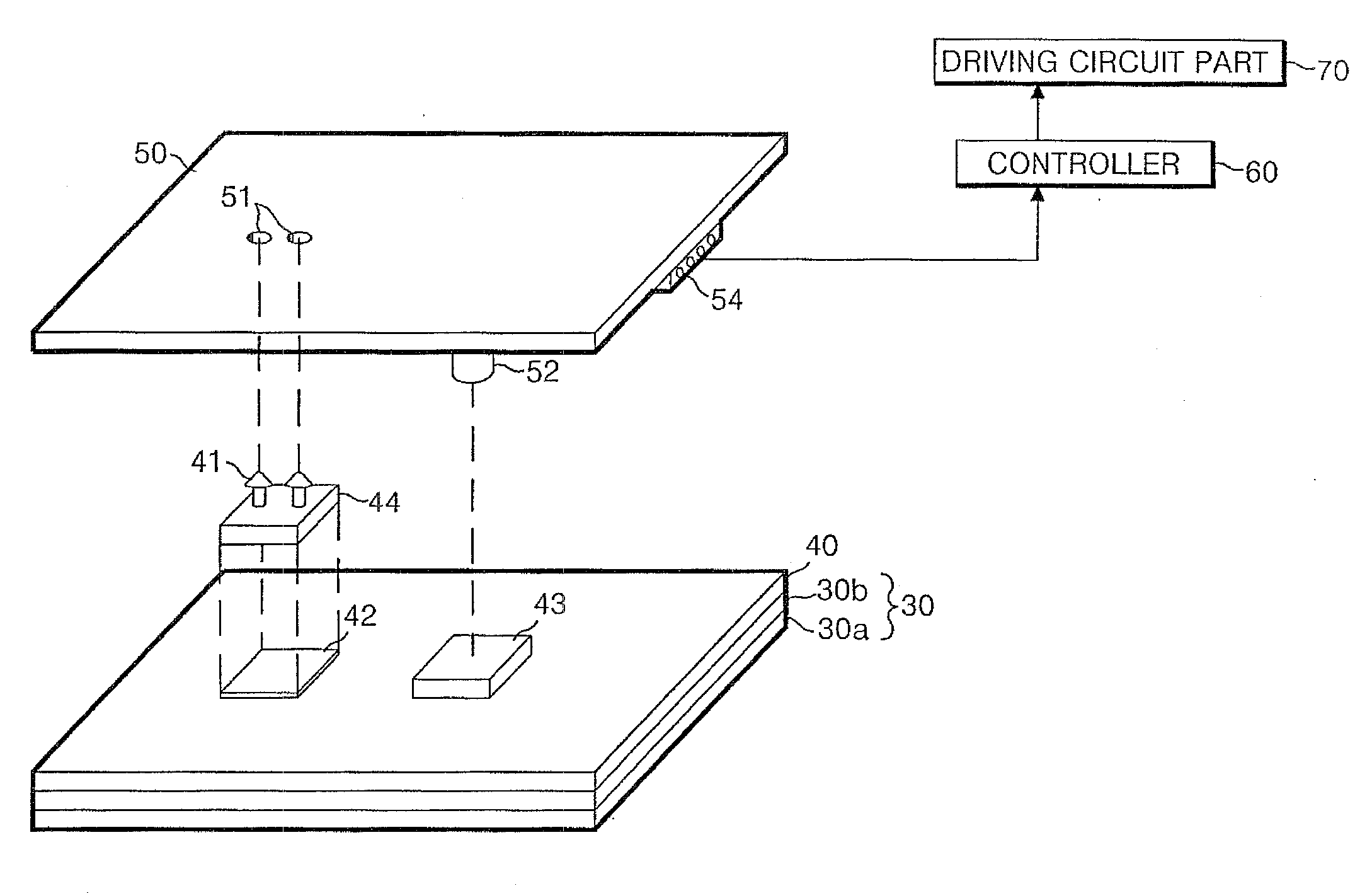

[0047]FIG. 5 is a configuration of an apparatus of driving a plasma display panel according to an embodiment of the present invention, and FIG. 6 is a configuration of the plasma display panel shown in FIG. 5 rotated by 180°.

[0048]Referring to FIGS. 5 and 6, a PDP according to the present invention includes: a panel 30; a heat-proof plate 40, attached on a rear surface of the panel 30, for dissipating a heat generated upon driving the panel 30; a sensor PCB 50 having a temperature sensor 50 installed thereon for detecting a temperature of the panel 30; a controller 60 for producing different control signals in accordance with the temperature of the panel detected by the sensor PCB 50; and a driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com