Telescopic hand tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

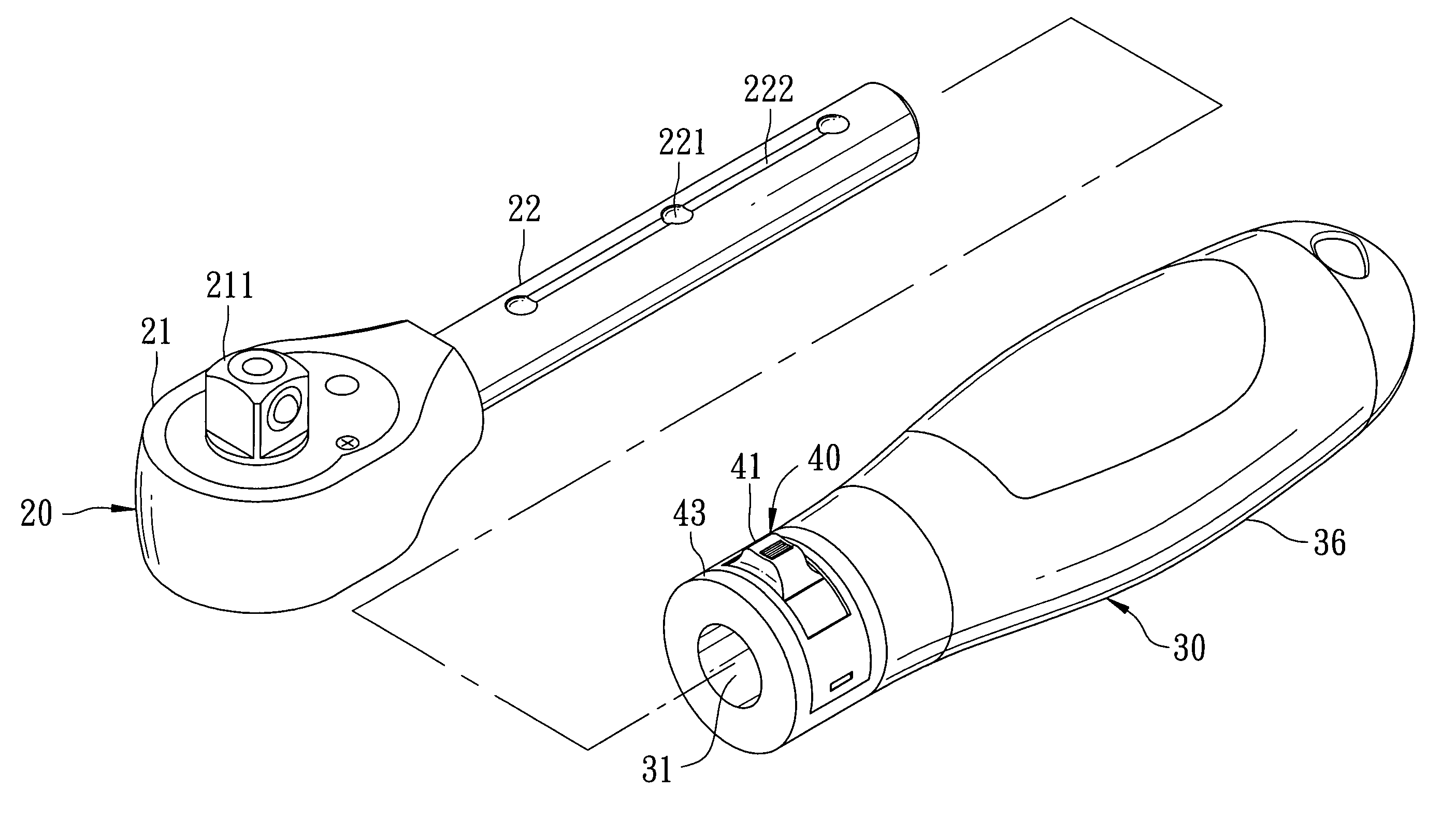

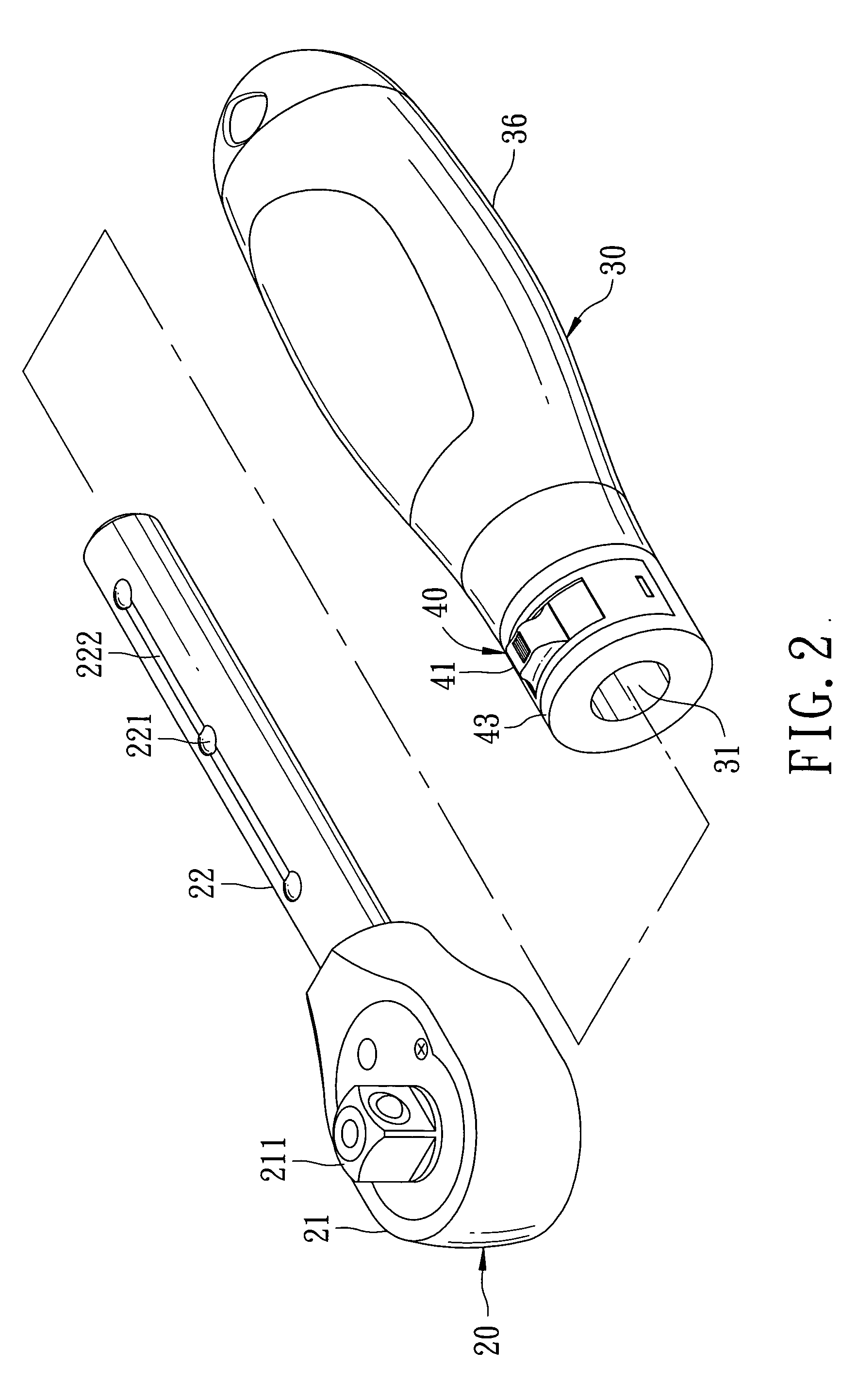

[0016]As shown in FIGS. 2 and 3, a first preferred embodiment of a telescopic hand tool in the present invention is composed of a main body 20, a bar 30 and a positioning device 40.

[0017]The main body 20 is provided with a working head 21 formed in its front portion and a telescopic bar 22 formed in its rear portion. The working head 21 is provided with a ratchet set 211 for engaging with a tool. The telescopic bar 22 formed cylindrical is provided with plural restricting ball holes 221 bored axially with equidistance, and a shallow groove 222 concaved with a depth lower than that of the restricting ball holes 221, for communicating with the restricting ball holes 221.

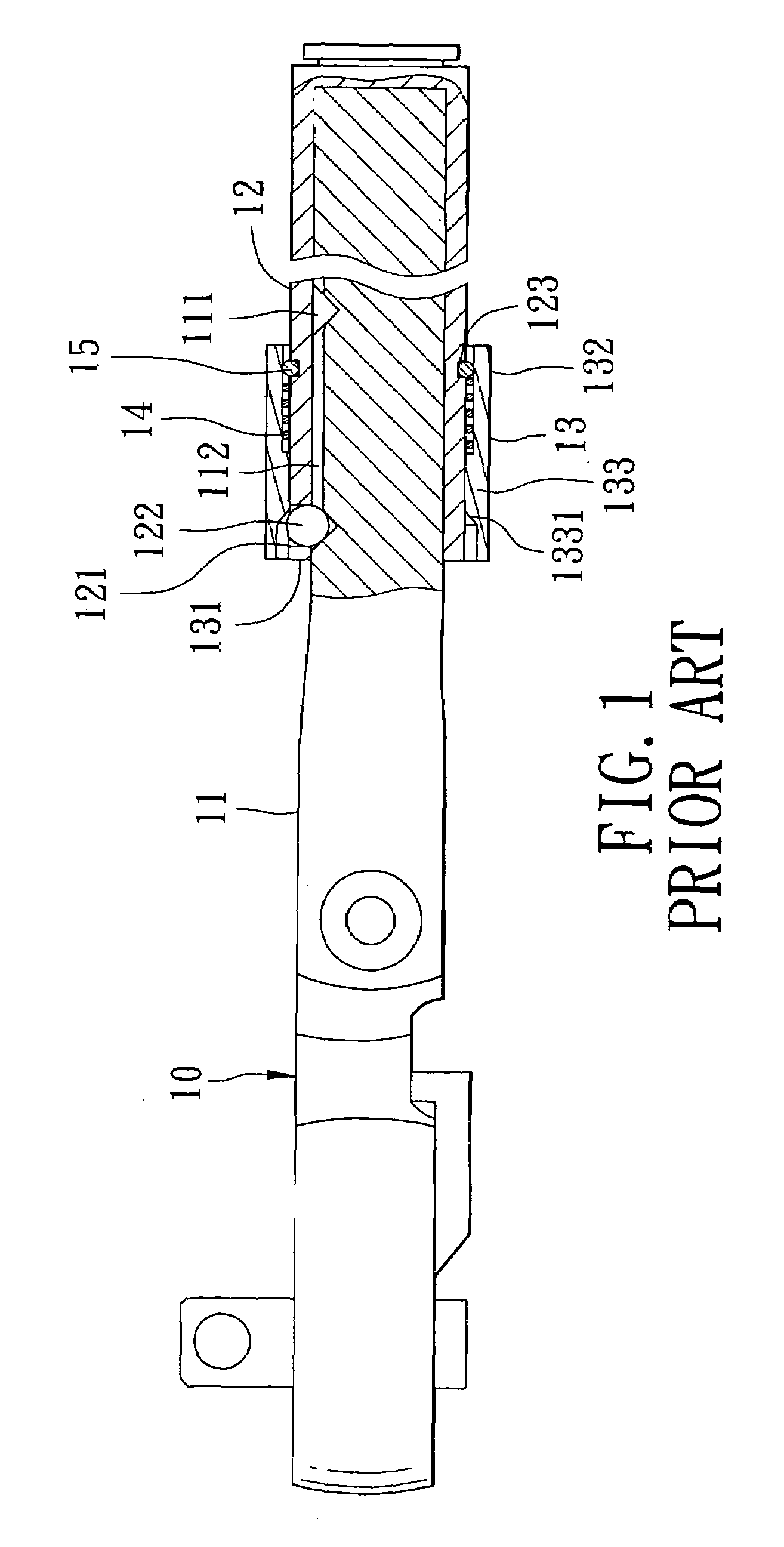

[0018]The bar 30 formed as an annular column is provided with an axial hole 31 bored axially from its one end for engaging with the telescopic bar 22 of the main body 20, a sliding groove 32 dug near the opening of the axial hole 31 to form as a two-step ladder, and a ball hole 33 bored in the sliding groove 32 for a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com