If the harvest cut is made above the ideal cut height, the higher than desirable cut will result in harvest losses in the form of unharvested

raw material, perhaps occasioning the need for an additional harvesting cut to try to try to recover the remaining unharvested

raw material, with additional expenditures of time and additional

wear and tear upon the harvesting equipment, or the loss of revenue from the unharvested

raw material.

If the harvest cut is made below the ideal cut height, various, other, undesirable consequences may result.

A harvest cut below the ideal height will not only result in increased damage to the

plant, thereby decreasing the long term productivity of the cane plantation, but also in higher mineral levels in the harvested cane, and will cause increased damage to the base cutter knives, resulting in accelerated wear of such knives due to the constant wear against the soil.

Such wear against the soil reduces productivity due to the need for more frequent stoppages of the machine for maintenance and for knife changes into fixed or floating base cutter units, and also results in higher motor and energy costs and greater waste since the equipment is required to operate in adverse or less than desirable conditions.

However, even a good operator's ability to accurately monitor and track soil irregularities, especially over an extended period of time and from a vantage point distanced to some degree from the cutting knives, is limited, and soil and other environmental conditions can compound the difficulties.

Especially if the soil is not well prepared, it is difficult for the operator to accurately adjust, in an ongoing manner, the height of the cutting knives so as to, on the one hand, avoid raw material losses, generally of the richest portion of the

plant, yet, on the other hand, avoid premature wear of the base cutter knives and minimize the feeding of minerals.

In practice, however, due to system design constraints and in order to prevent damage to the harvesting machine and its components, movement of the base cutter unit relative to the chassis is limited to some maximum such that, if a significant irregularity in the ground contour is encountered, excessive displacement of the base cutter unit relative to the chassis is blocked by a respective windowsill or movement limit that is generally associated with the machine chassis.

Consequently, when ground irregularities that exceed the machine's design capabilities are encountered, the base cutter unit cannot be moved sufficiently to be able to properly track and follow the

ground track irregularity and the desired work height cannot be maintained.

However, such adjustment in the chassis height also effects a change in the nominal work height as established by the height of the chassis, and, if a corrective readjustment is not thereafter made after the significant ground irregularity has been cleared, the working height for the cutting operation, though perhaps improved as the base cutter unit traversed the ground irregularity, may thereafter, when the base cutter unit has cleared the ground irregularity, be less than optimal.

In light thereof, because of the frequency with which unexpected soil irregularities and intensities are encountered, and because of the degradation of responsiveness experienced by even the most skilled operators over the course of long operation periods, such well-known systems and their techniques have seldom been able to consistently achieve the efficiency desired.

However, even under ideal conditions and with well-rested and competent operators, the time

delay between the operator's recognition that some corrective adjustment is desirable and his actions to effect the desired adjustment results in time periods during which the harvesting cut is less than ideal.

In addition, the existence of conditions which ideally would result in a recognition by the operator that some corrective adjustment is desirable is not always readily apparent or detectable by the operator.

For example, if the ground surface includes a sudden elevation, but the soil is loose and not very resistant, when a cutter disk unit of a particular harvesting machine encounters such elevation, the weight of an under-central base cutter unit skate may be such that that elevation is not appropriately detected and that ground irregularity is not appropriately tracked and made evident to the operator.

In such a situation, even though the cutter disk may be operating to an undesirable depth, and thereby demanding higher

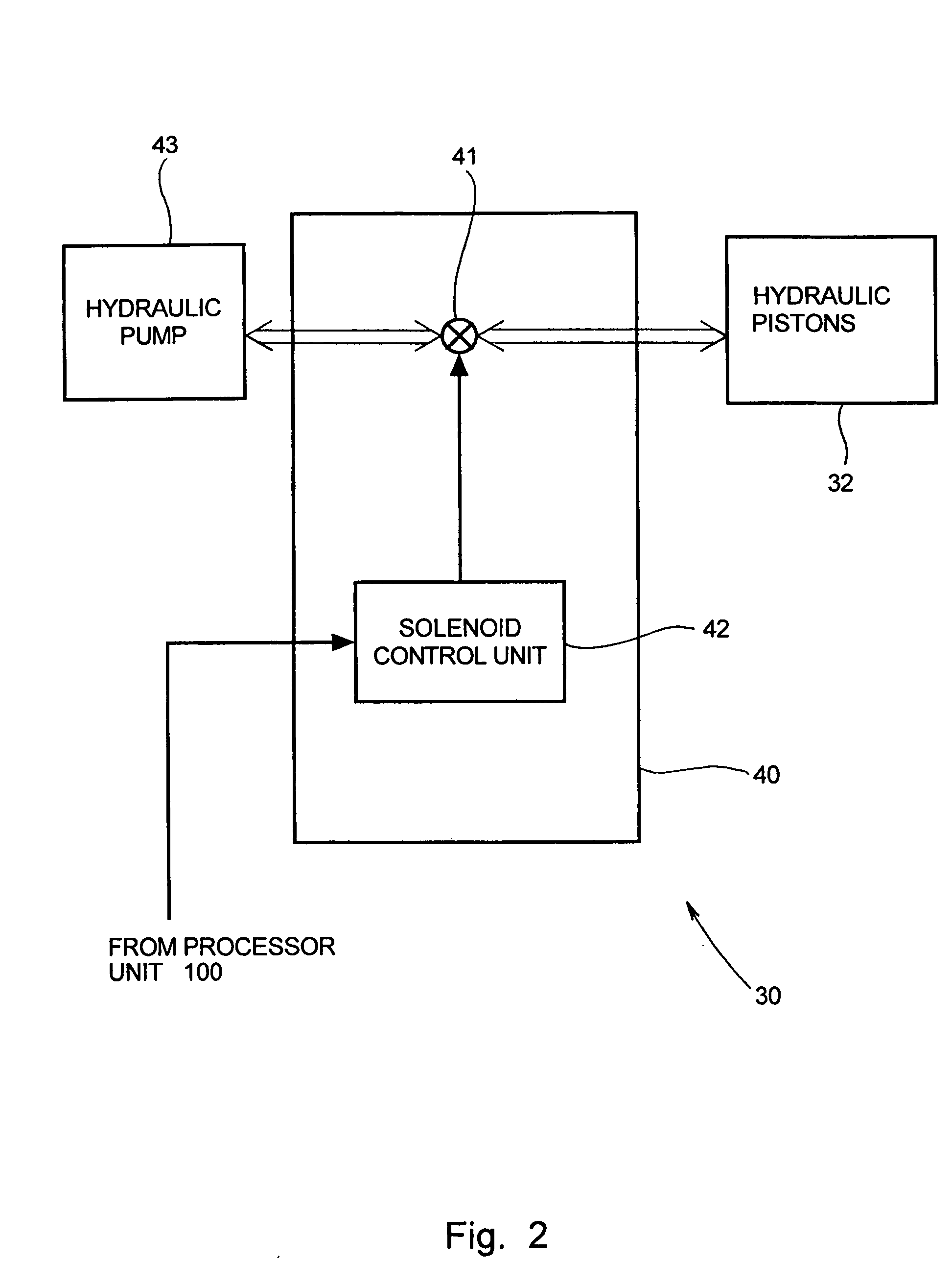

hydraulic pressure, the operator may be unaware of the condition.

While various constructions have been developed that have lessened to some extent the need for reliance upon manual adjustments, such as by employing height adjustment systems that are only semi-manual or which are partially automated to be responsive to certain monitored conditions, such as detected cutting pressure required or a detected ground surface irregularity, no known construction has heretofore employed a system for automatedly adjusting the height of the cutting apparatus to maintain an approximately desired cutting height without the need for constant and continuing operator attention and intervention.

Although such a system affords certain advantages and provides the operator with greater flexibility in controlling the height of the cutting apparatus, each operating mode continues to suffer from the attendant disadvantages for that mode, and significant continuing operator attention and intervention remains necessary.

Login to View More

Login to View More  Login to View More

Login to View More