Snow melting system and method with direct-contact water heater

a technology of direct contact and water heater, which is applied in the direction of fluid heater, lighting and heating apparatus, ways, etc., can solve the problems of low fuel efficiency of devices, inability to achieve high melting rate per unit of fuel consumed or electricity used, and high operating costs, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

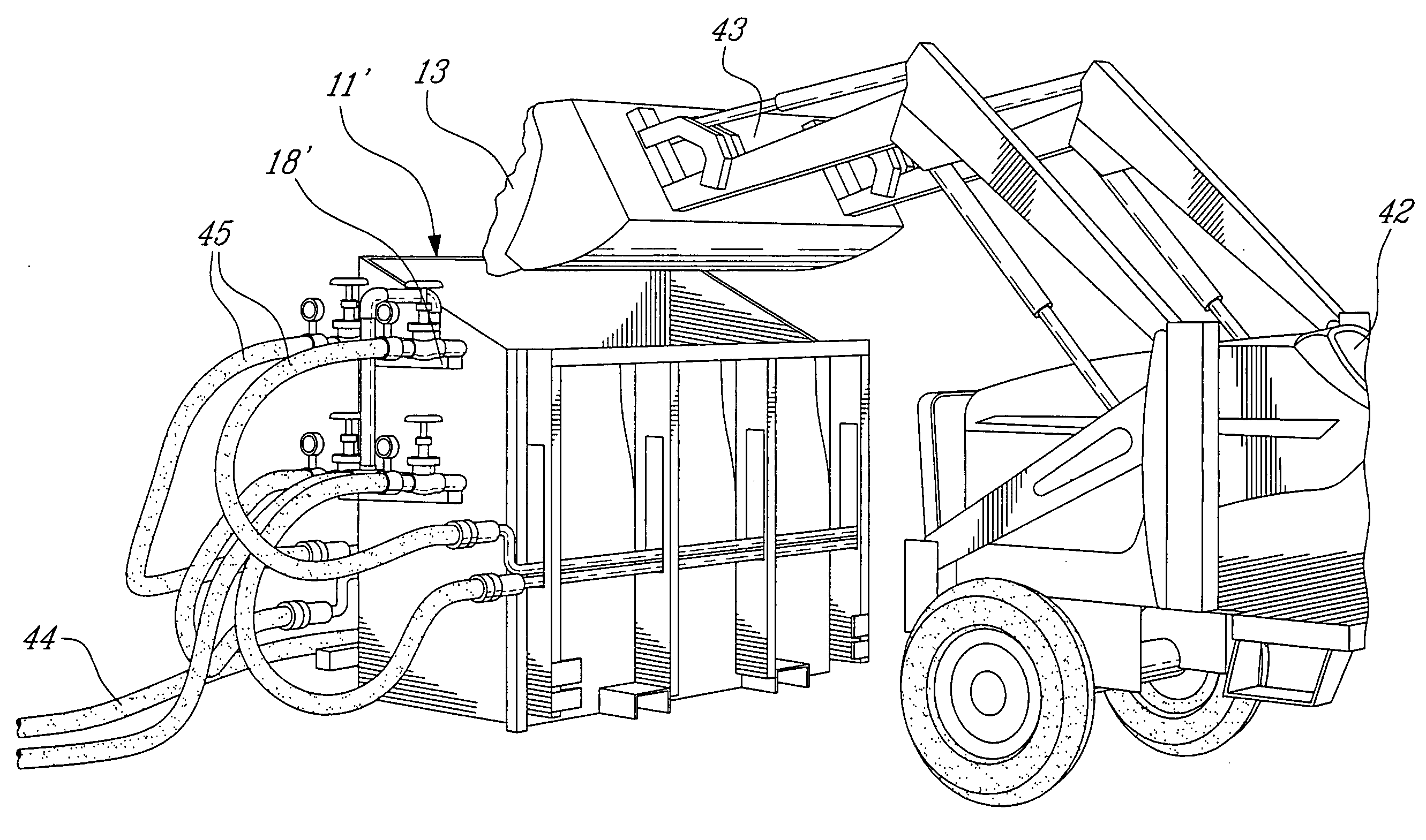

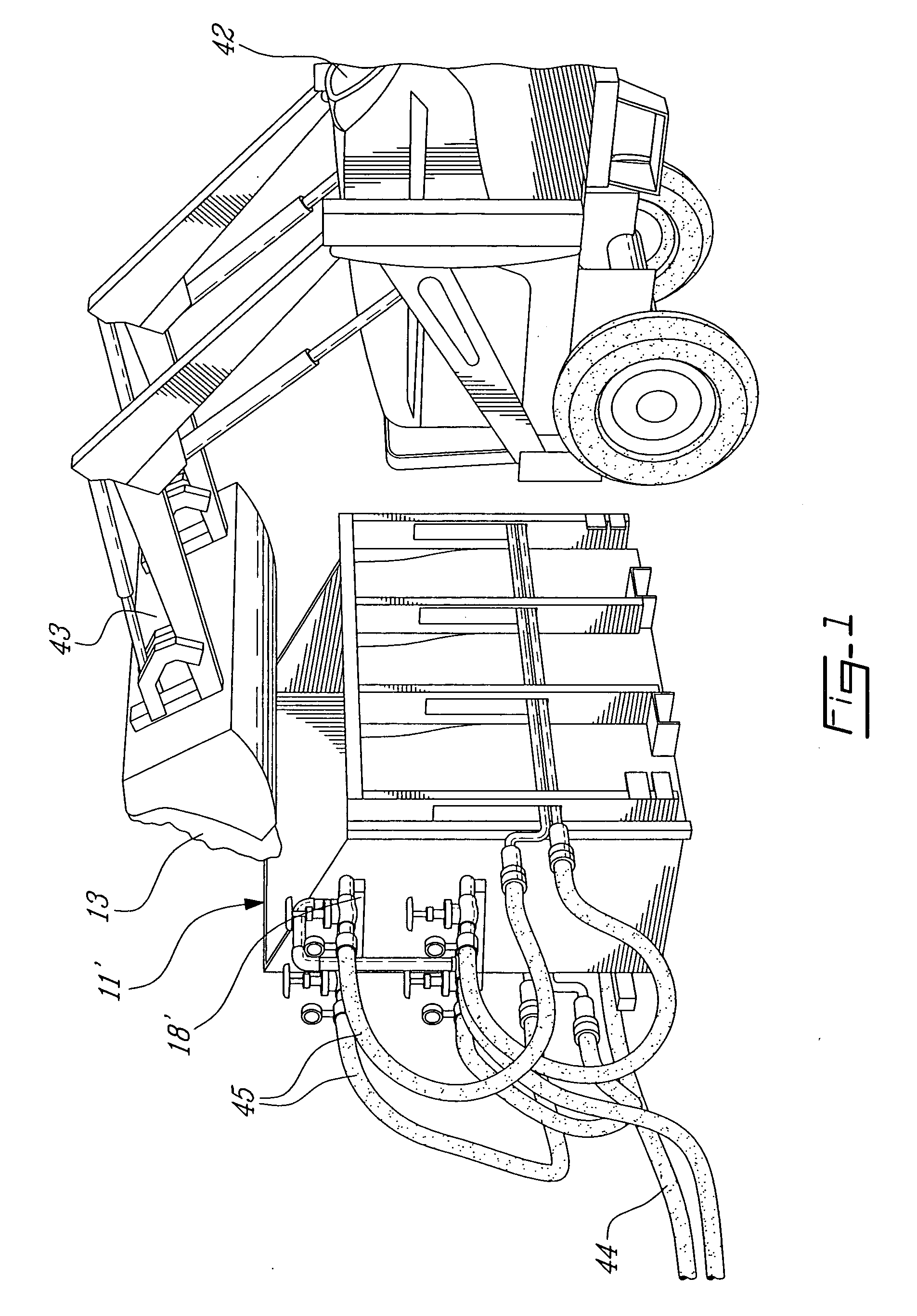

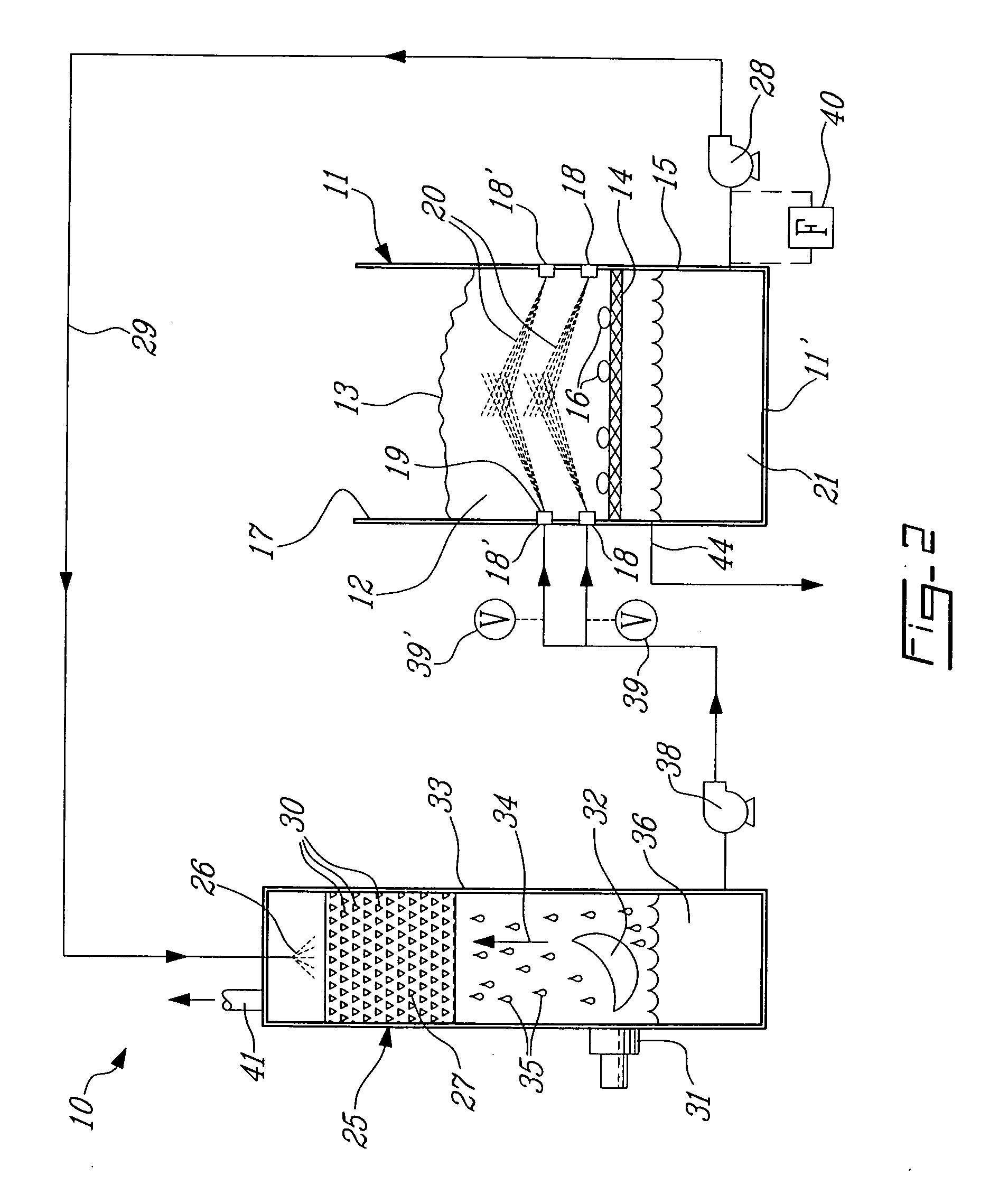

[0017]Referring now to the drawings and more particularly to FIG. 1, there is shown generally at 10 the snow melting system of the present invention. It is comprised of a snow melting housing 11 which can have many forms such as a stationary bin 11′ as shown in FIG. 2 or that bin or other housing could be mounted on a transport vehicle together with its associated equipment. The snow melting housing 11 defines therein a snow melting chamber 12 extending from above a support screen 14 which extends across the opposed side walls 15 of the housing 11 whereby to filter out debris 16 collected with the snow 13. The housing 11 has an open top end 17 to load snow into the snow melting chamber 12. The open top end 17 can also be provided with a suitable closure, not shown.

[0018]As hereinshown a plurality of water spray nozzles 18 are mounted in the housing side walls 15 all about the snow melting chamber 12. These water spray nozzles 18 have their jets 19 oriented upwardly at a slight angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com