Pocket rail construction

a technology of pocket rails and guard rails, which is applied in the direction of construction, building types, bulk storage containers, etc., can solve the problems of many building codes not approuving their use and the application of vinyl materials remains somewhat limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

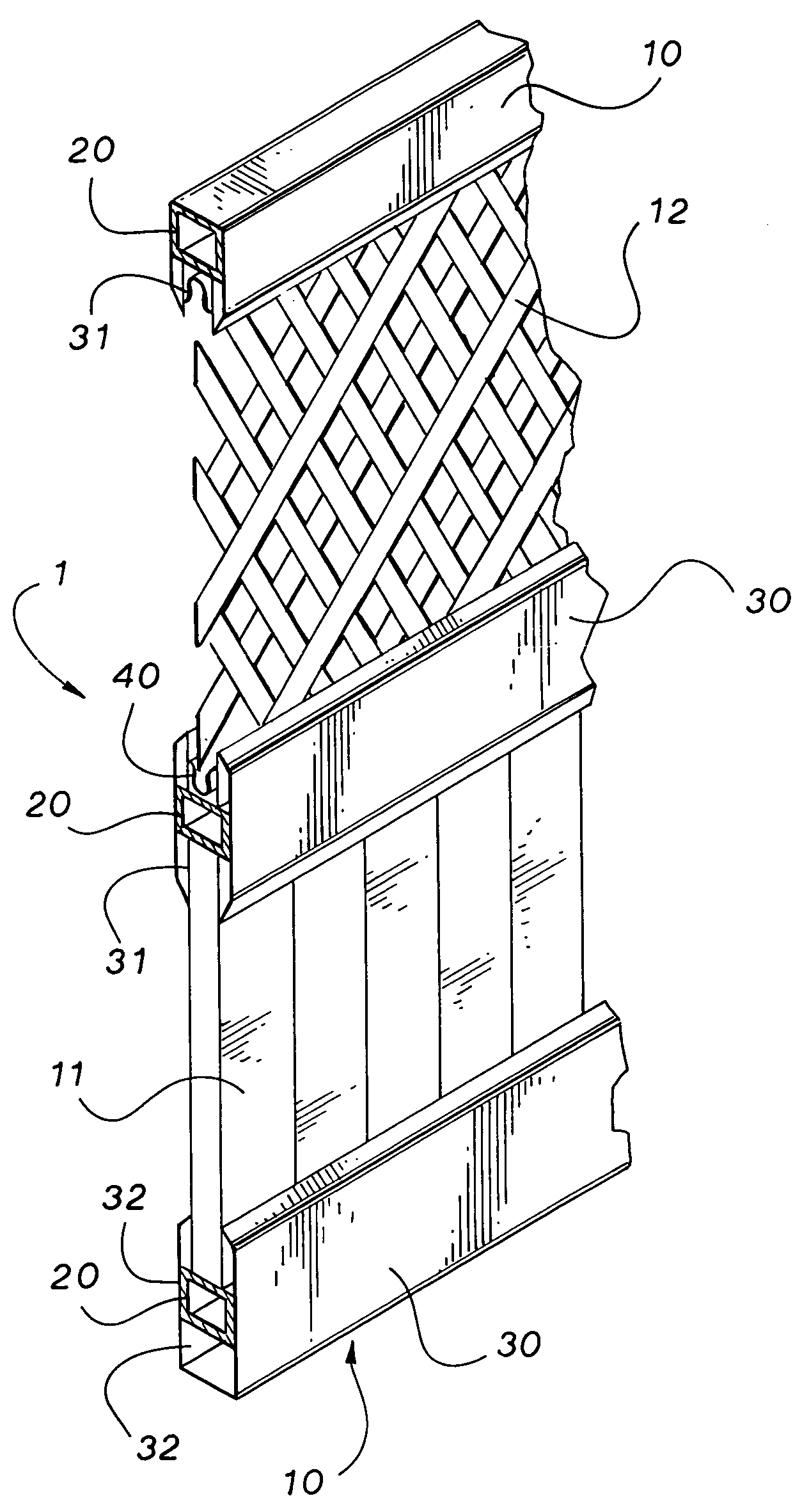

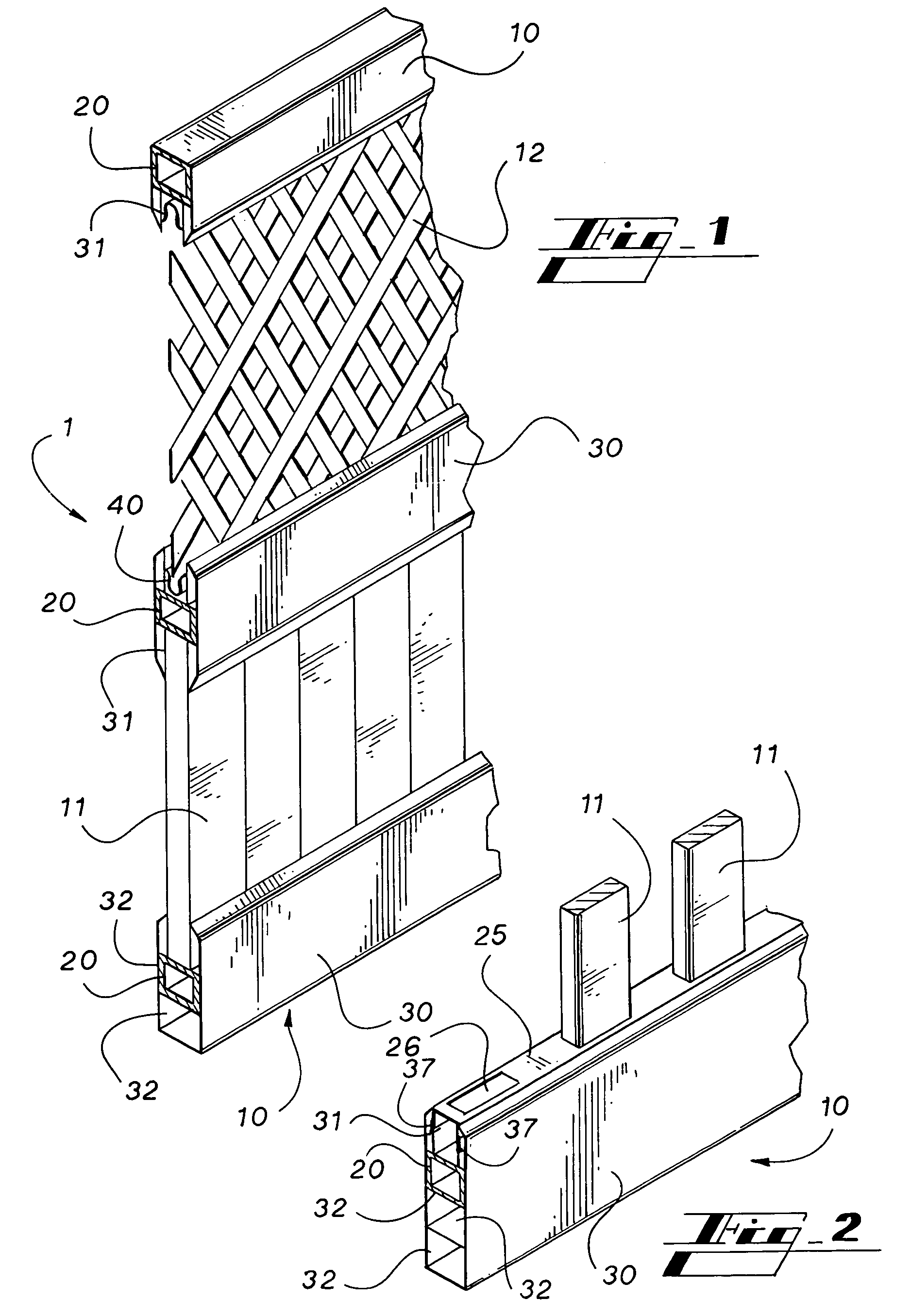

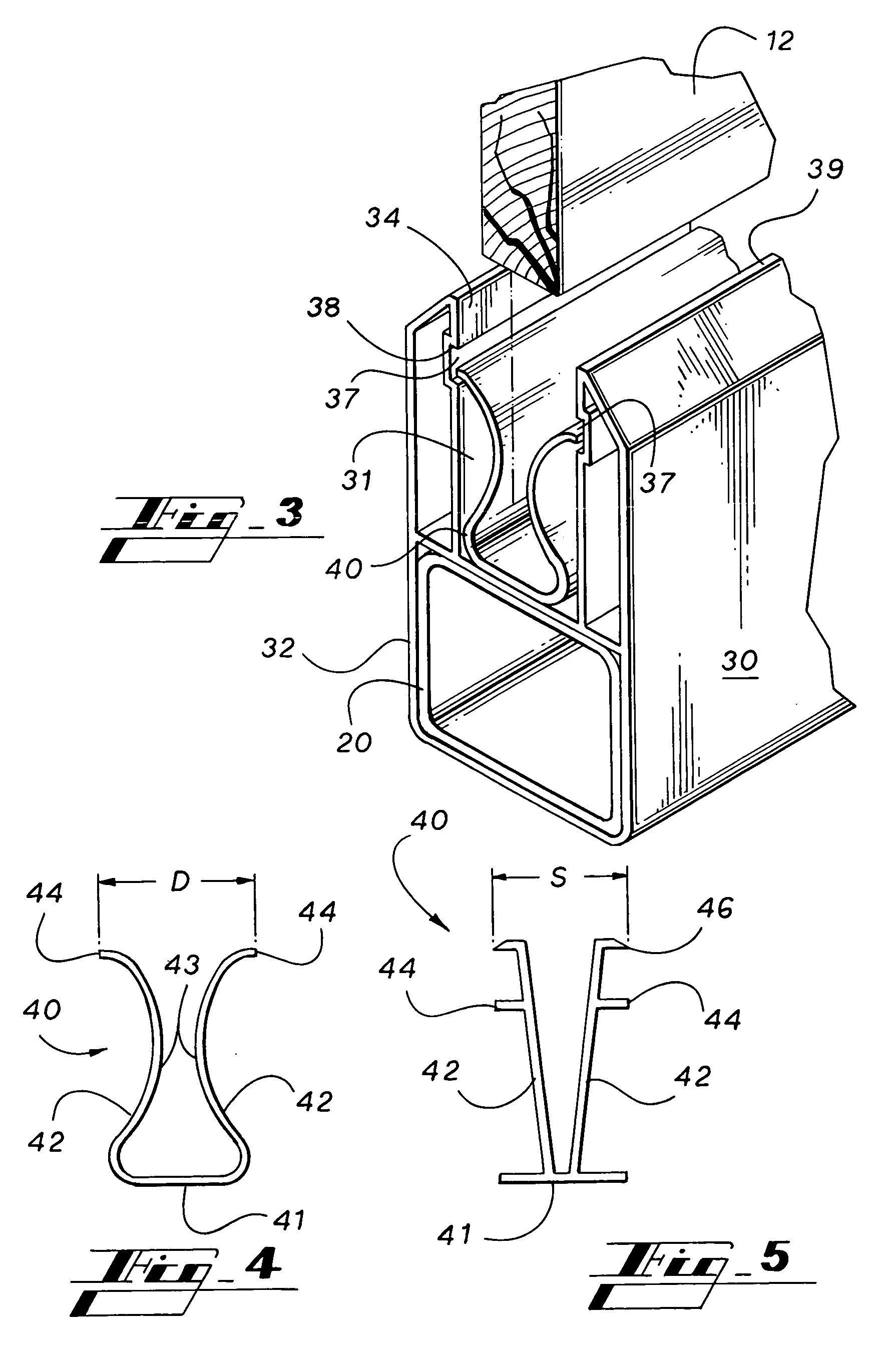

[0024]Referring to the drawings for a more complete description of the invention, FIG. 1 depicts a fence section 1 constructed with an pocket rail 10 constructed according to an embodiment of the present invention. As may be seen rail 10 comprises an elongated rigid substrate support member 20, which provides support and structure for rail 10, and an outer sleeve 30 having at least one groove or channel 31 defined along a longitudinal side of sleeve 30 and at least one chamber 32 defined to receive and enclose support member 20 therein.

[0025]The support member 20 is comprised of a metallic, composite, or other approved construction material according to applicable building codes, and is preferably made of aluminum. It may be formed as an I-beam, channel, or tubular construction so as to provide the required structural strength and dimensioned to be received within in chamber 32.

[0026]The outer sleeve 30 is preferably made of a vinyl, plastic, composite or similar such materials, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com