Interleaved Transparent Cellulose Paper with Opaque Adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

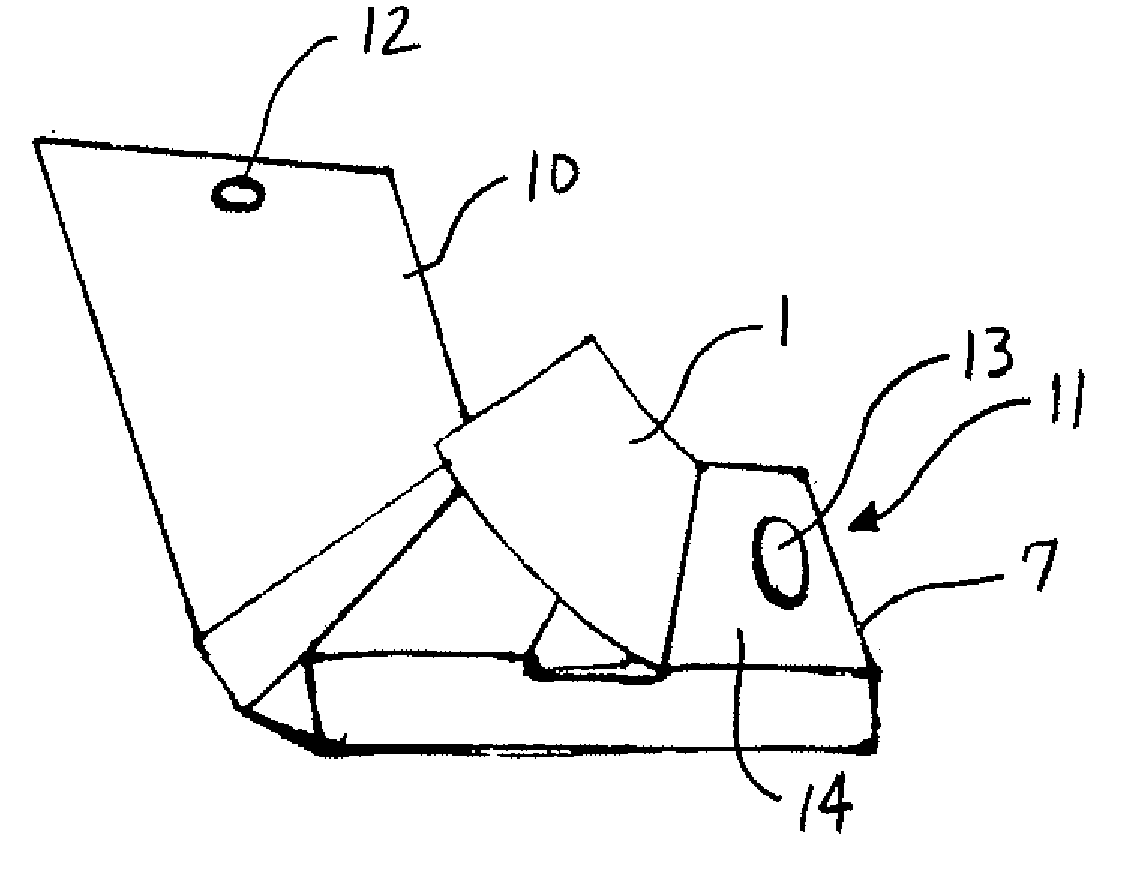

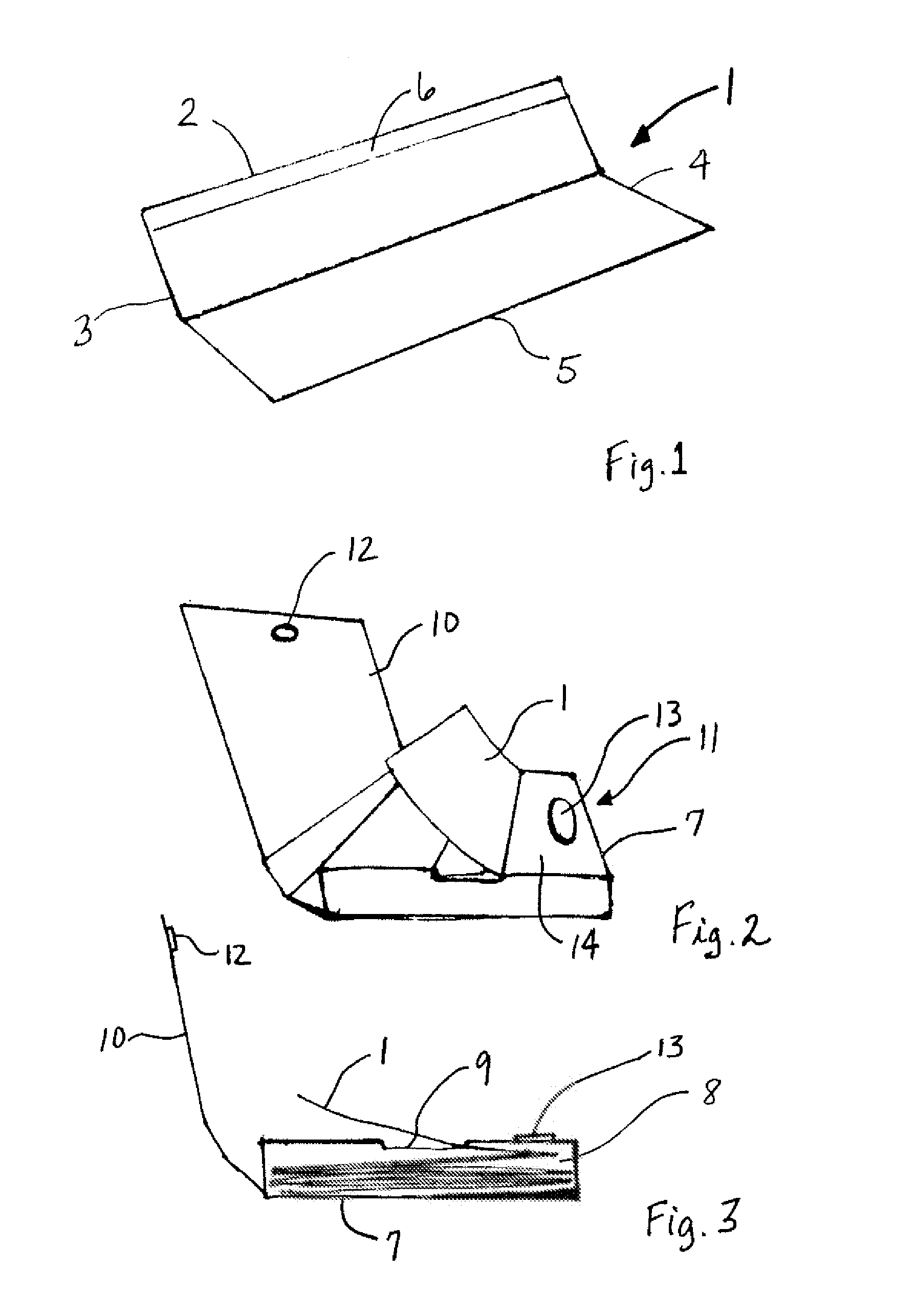

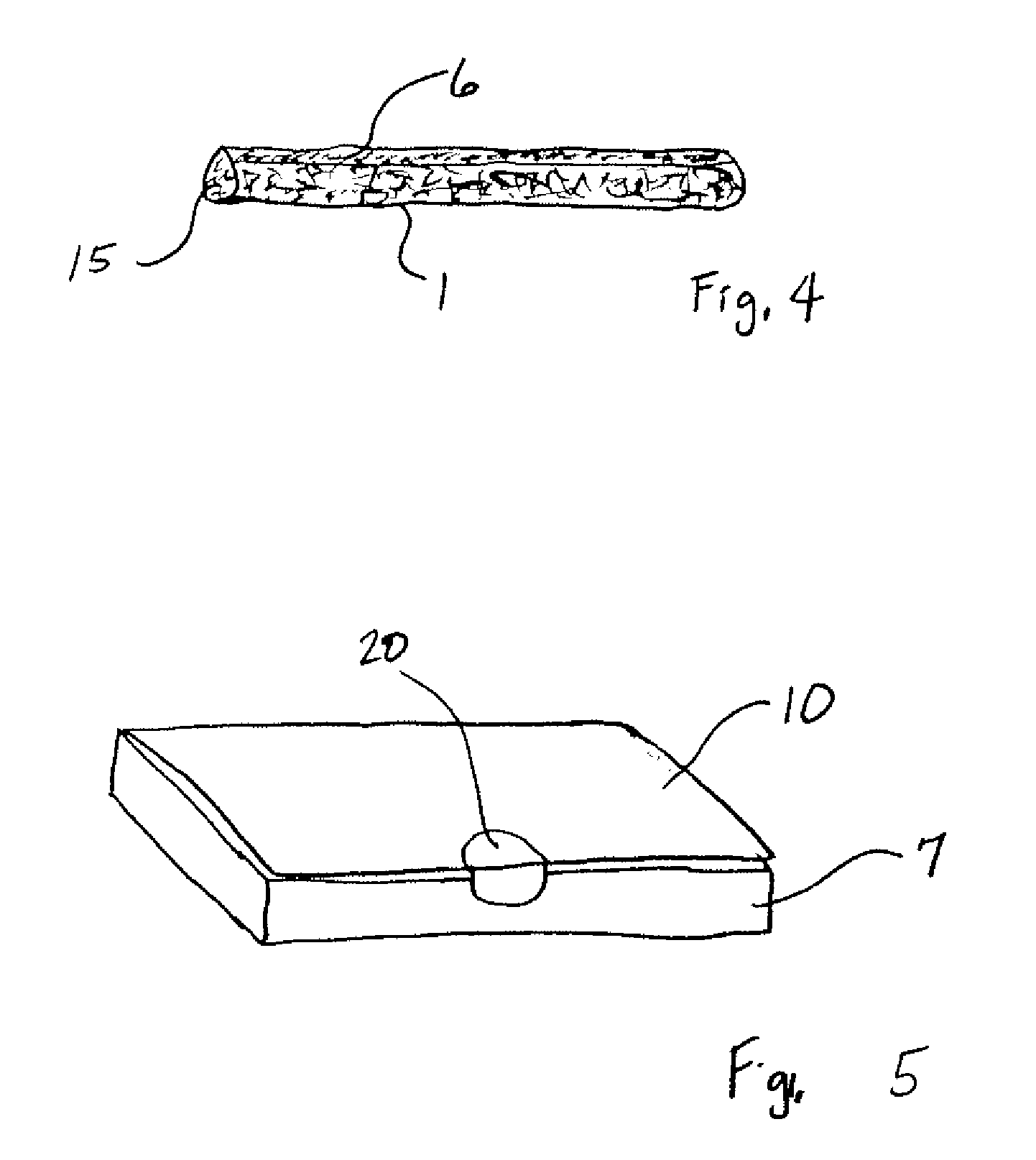

[0020]Turning now to FIG. 1, a highly transparent cellulose paper 1 is shown. Each flat sheet of paper 1 is cut so that it has four edges 2-5. A strip of adhesive 6 is applied to a top edge 2, wherein the weight of the adhesive gumline is in the range of 20-110 grams per square meter (gsm). In the preferred embodiment, the adhesive 6 is cellulose-based, although other adhesives may also be used which satisfy the requirements of adhering to the cellulose paper 1, such as a non-standard formulation containing acacia gum, sugar gum, or animal gum. The cellulose-based adhesive is preferably comprised of ninety-seven percent water, two percent cellulose gum, and one percent flavoring. Optionally, a pigment or food coloring is also added to create an opacity when dry so that the adhesive line can be seen on the paper 1. The components are preferably food grade and the amounts may be adjusted accordingly if it is desired to eliminate the flavoring. The source of the cellulose gum in the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com