Linear Table Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

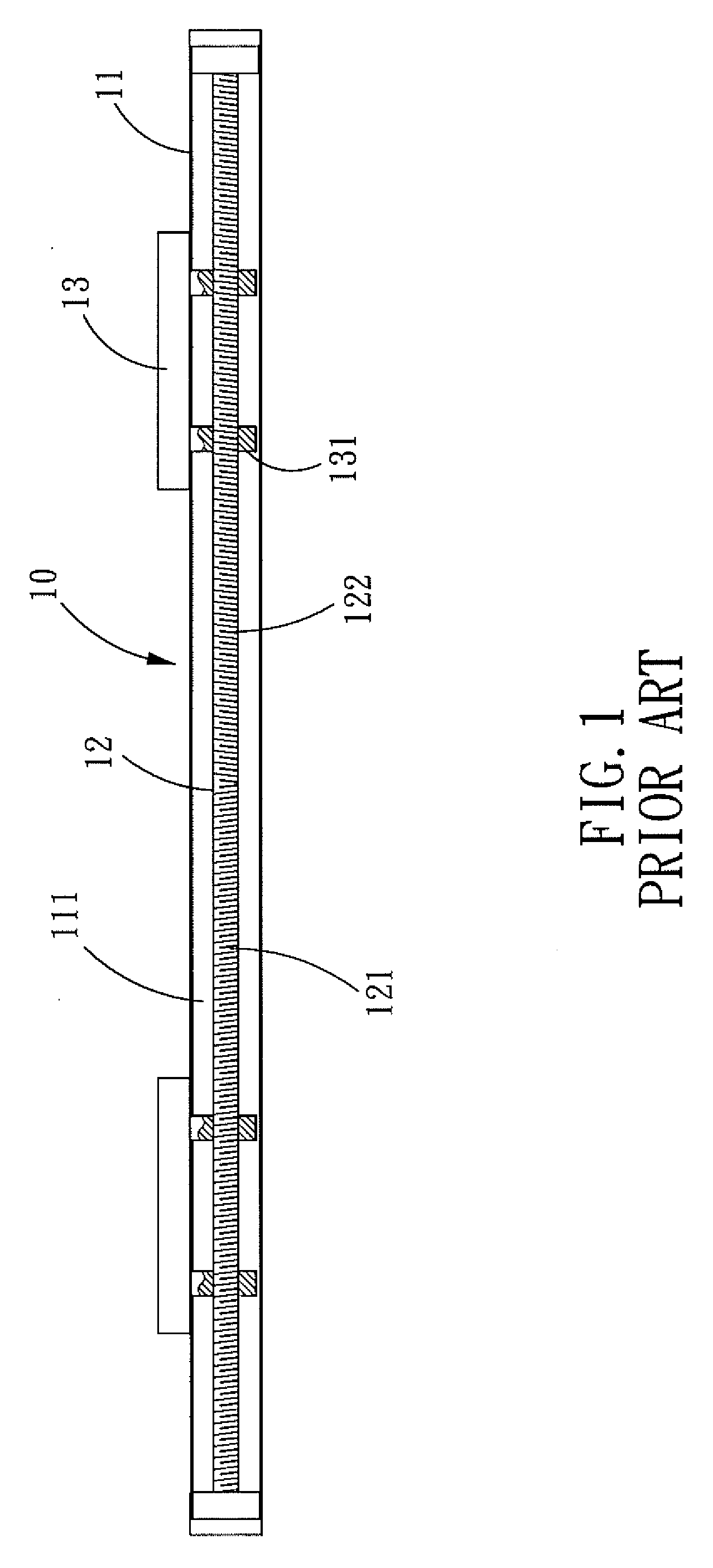

[0023]The present invention will be more clear from the following description when viewed together with the accompanying drawings, which show, for purpose of illustrations only, the preferred embodiment in accordance with the present invention.

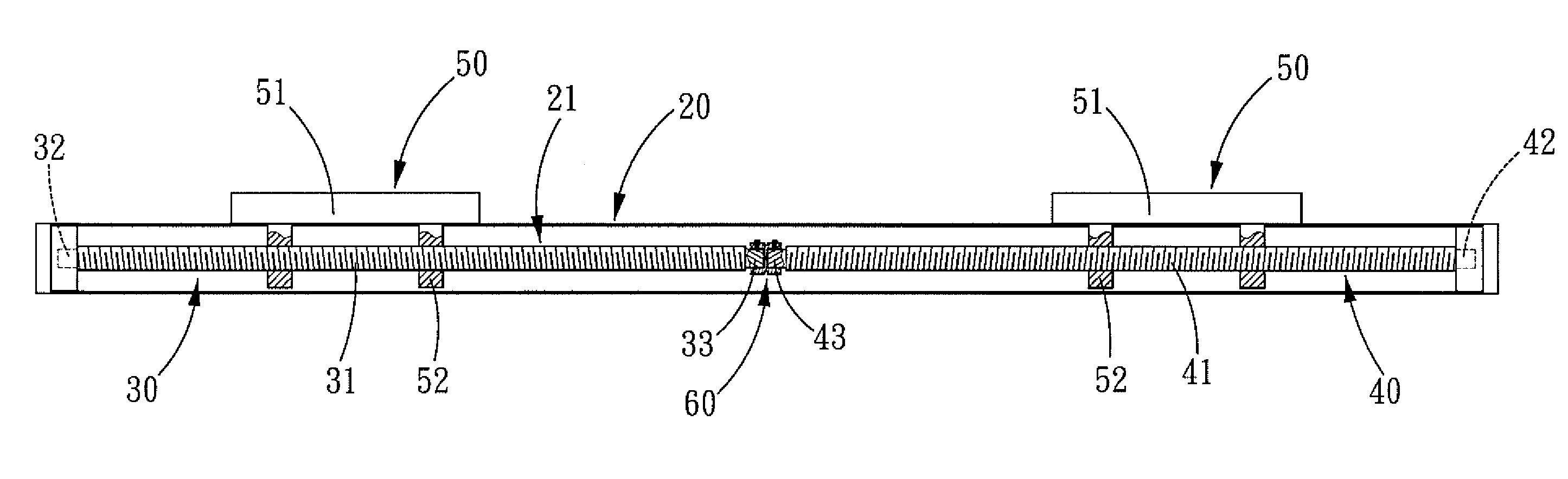

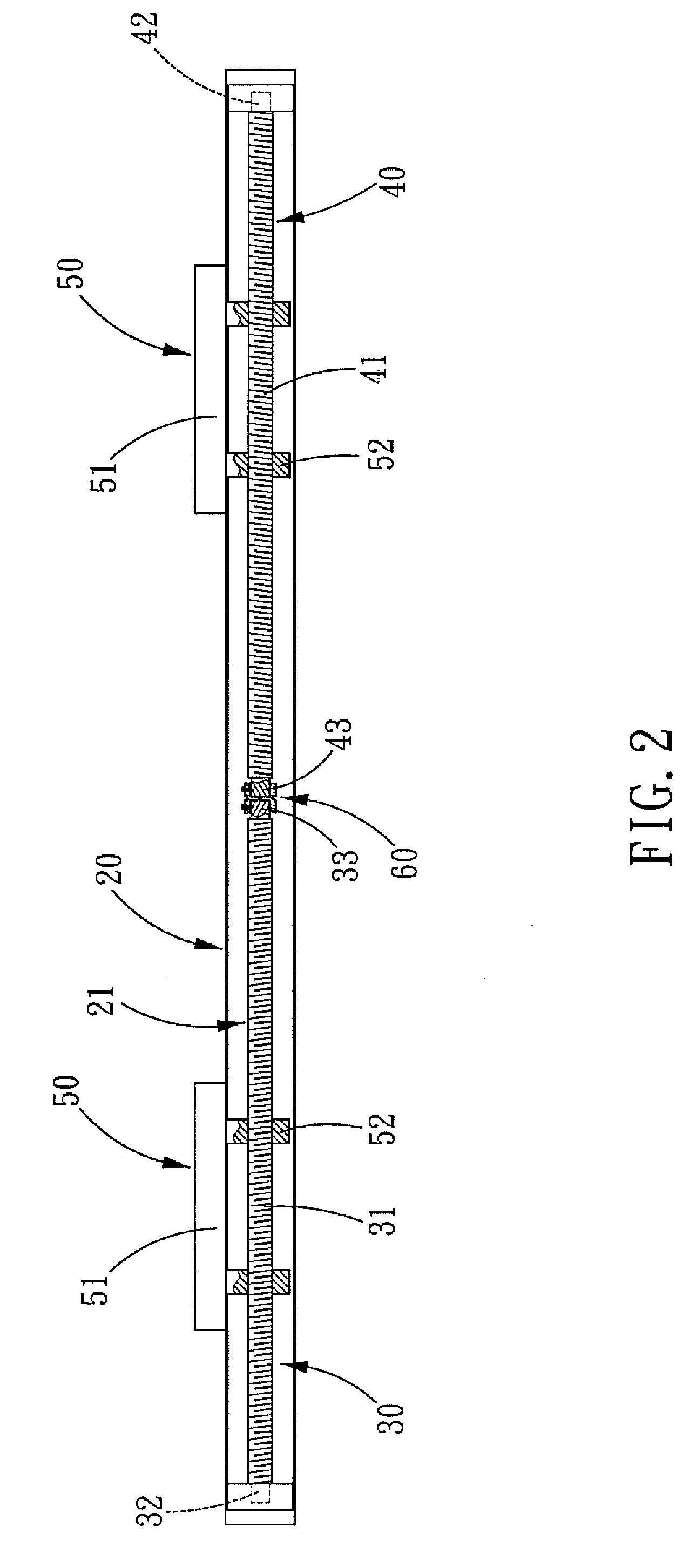

[0024]Referring to FIGS. 2-7, a linear table structure in accordance with the present invention comprises: a groove body 20, a first screw rod 30, a second screw rod 40, two sliding seats 50, a connecting calibrating assembly 60, and an assistant member 70.

[0025]The groove body 20 is interiorly defined with a receiving space 21.

[0026]The first screw 30 is formed on its outer surface with a first threaded section 31, at one end of the first threaded section 31 is axially formed a first pivot portion 32, and at the other end of the first threaded section 31 is axially formed a first connecting portion 33.

[0027]The second screw 40 is formed on its outer surface with a second threaded section 41 whose pitch is the same as the pitch of the first th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap