Screw Rotor and Screw Fluid Machine

a screw fluid machine and screw rotor technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of large amount of discharge gas to be transferred through, unavoidable meshing phase where the screw rotors are interfering with each other, and inability to meshed to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

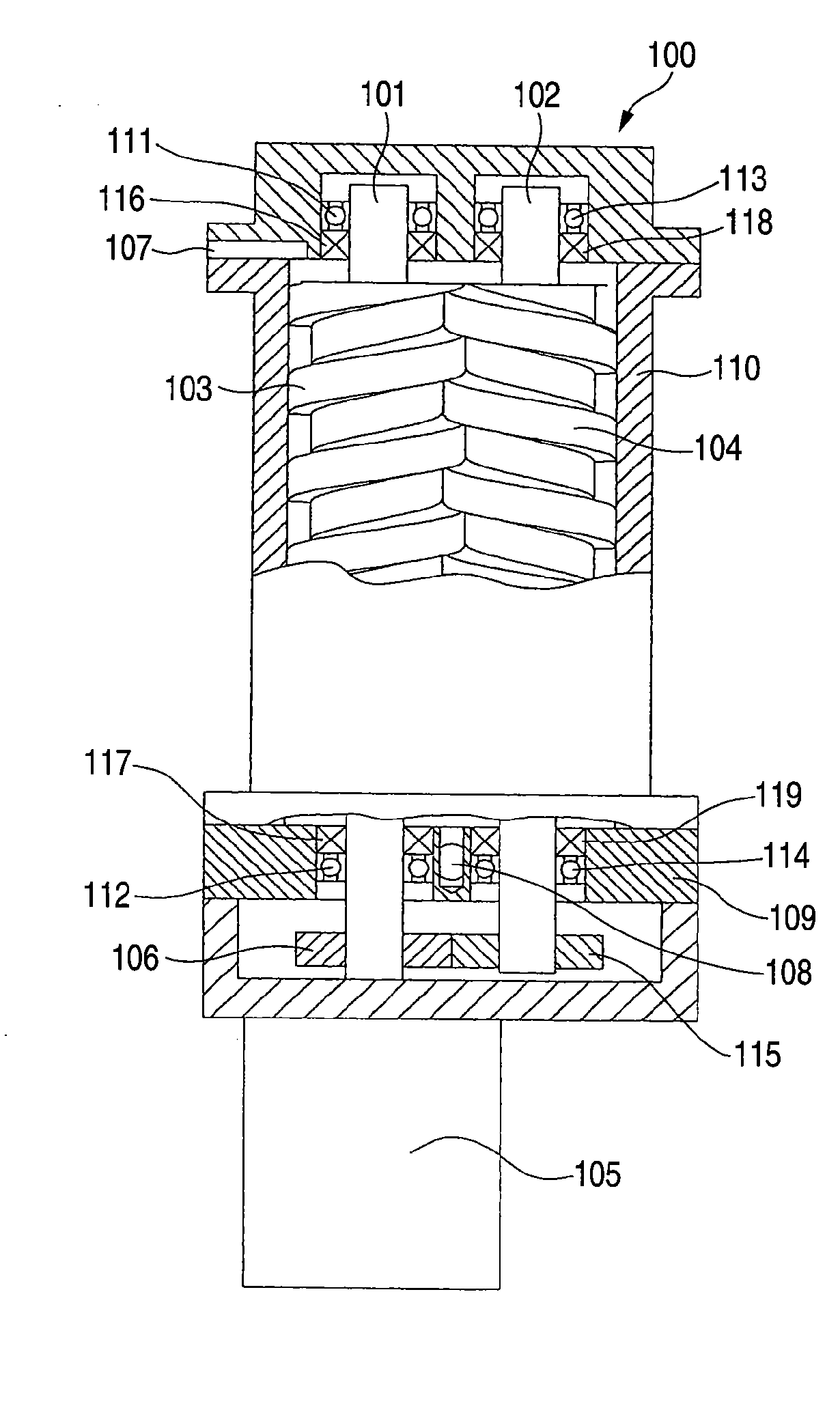

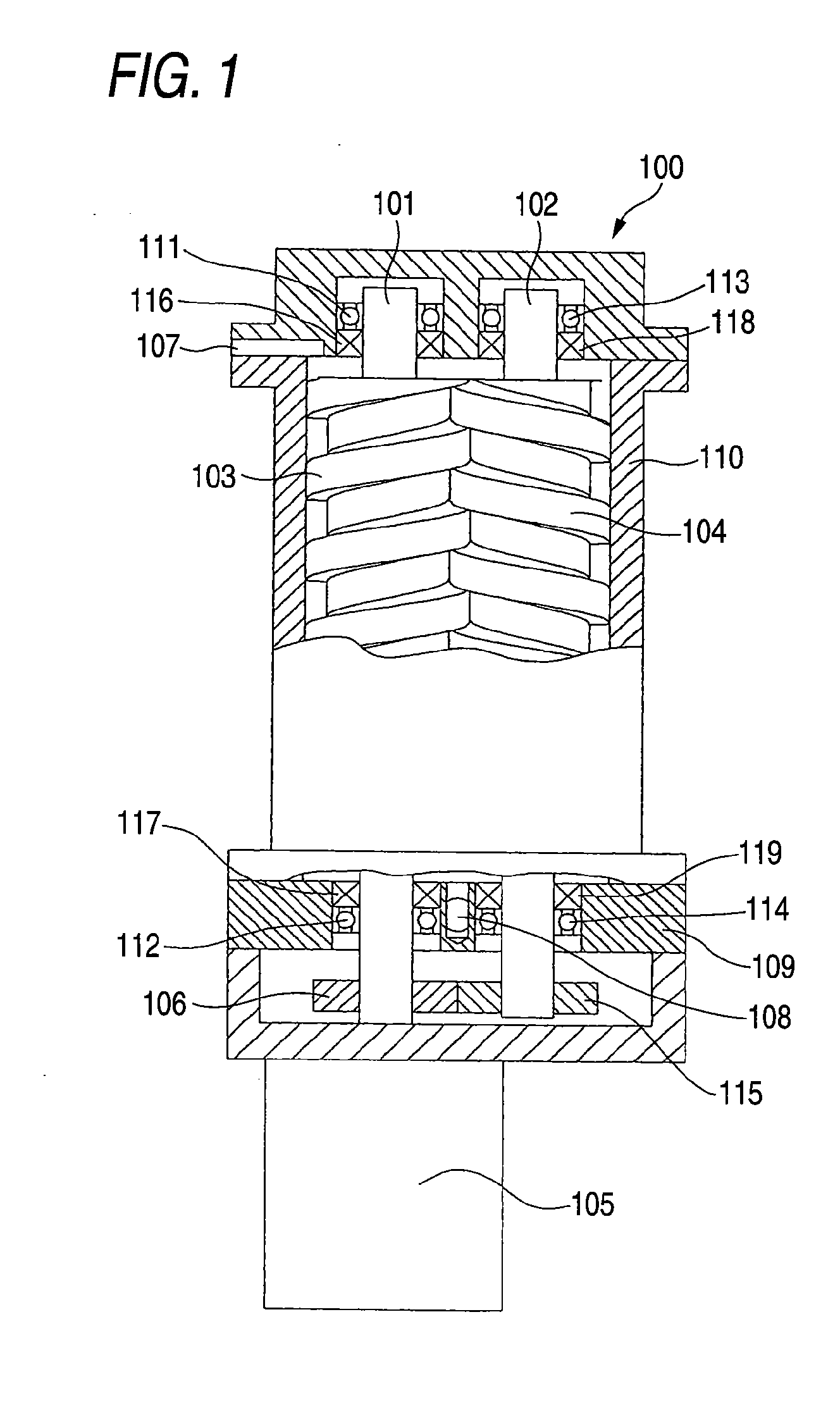

[0034]FIG. 1 shows an embodiment of a screw type dry vacuum pump 100 in which screw rotors according to the invention are employed.

[0035]The screw type dry vacuum pump 100, as shown in FIG. 1, are provided with two shafts 101,102 supported in a casing 110 through bearings 111,112,113,114. Screw rotors 103, 104 having screw grooves are provided on the shafts 101, 102. One shaft 101 is driven by a motor 105 and this rotation is transmitted through a timing gear 106 attached to the shaft 101 by meshing with the a timing gear 115 attached to the other shaft 102. That is, the screw rotors 103, 104 are rotated in synchronism with each other by means of the timing gears 106,115. The casing 110 is provided with a suction port 107 for introducing a discharge gas in a discharging chamber therefrom and a discharge port 108 for discharging the exhaust gas in a discharging chamber that is transferred from a side of the suction port 107. By the above construction, the screw rotors 103, 104 are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com