Fuze for a Projectile

a projectile and fuze technology, applied in the field of fuzes, can solve the problems of increased risk to the operator, unsuitable for automatic weapons or launch systems, and the fuze of the projectile, so as to achieve the effect of improving safety for the user and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

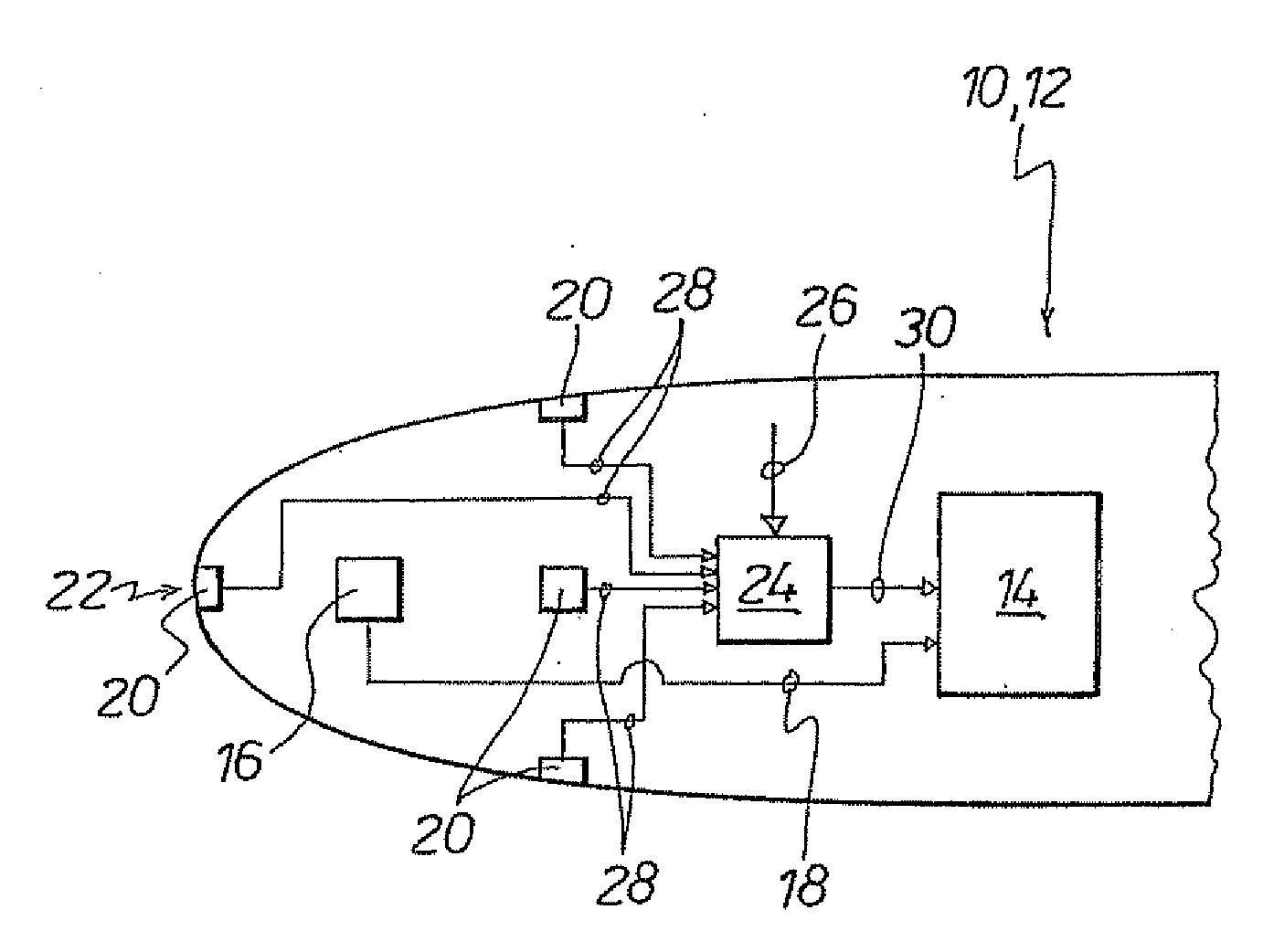

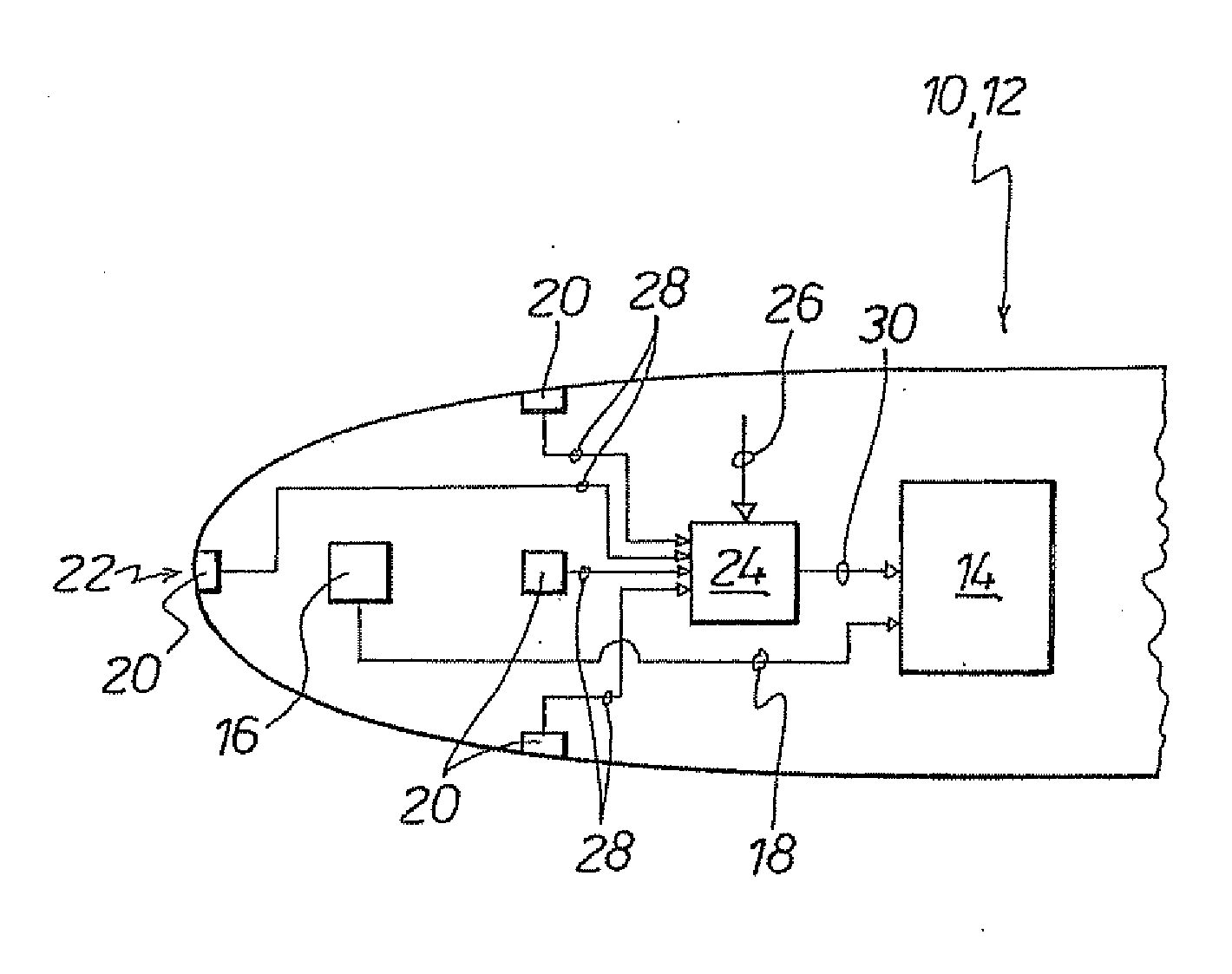

[0011]The figure illustrates a fuze 10 for a projectile 12. The faze 10 has a safety and arming unit 14 with a first and a second arming criterion. The first arming criterion uses the launch acceleration of the projectile 12. An acceleration sensor 16, which is operatively connected to the safety and arming unit 14, is used to detect the launch acceleration. This operative connection is indicated by the bent arrow 18.

[0012]The fuze 10 has sensors 20 at a distance from one another. One sensor 20 is provided at the faze tip 22, and further sensors 20 are arranged at a distance from it, at equal intervals from one another along the circumference of the fuze 10. The sensors 20 are pressure sensors and / or temperature sensors. The pressure sensors 20 are suitable for measuring the pressure difference in accordance with Bernoulli's Law, and / or the temperature sensors are suitable for measuring the temperature difference when an incident airflow strikes the fuze 10, during the flight phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com