Multi-Stage Trochoidal Vacuum Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

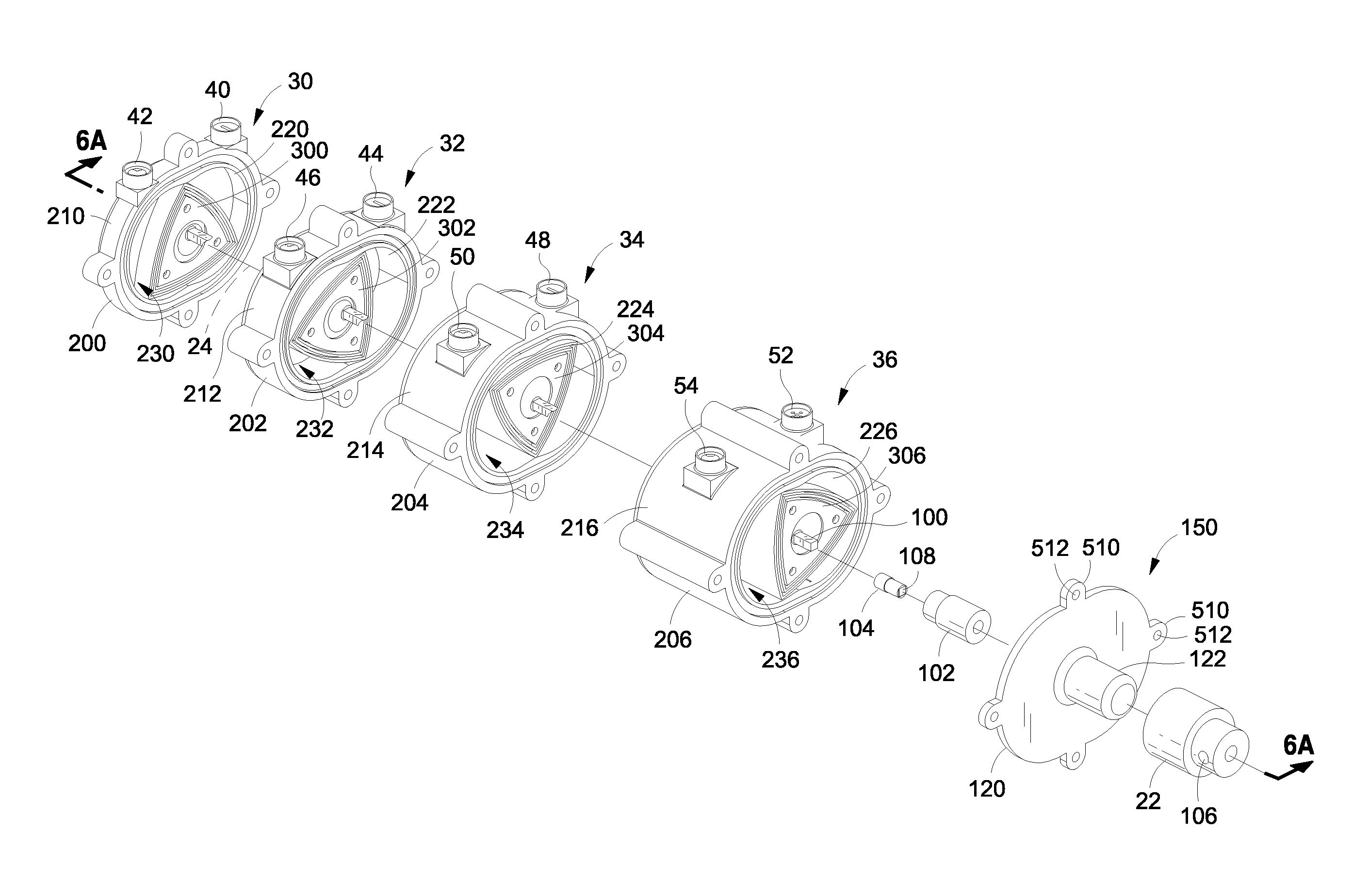

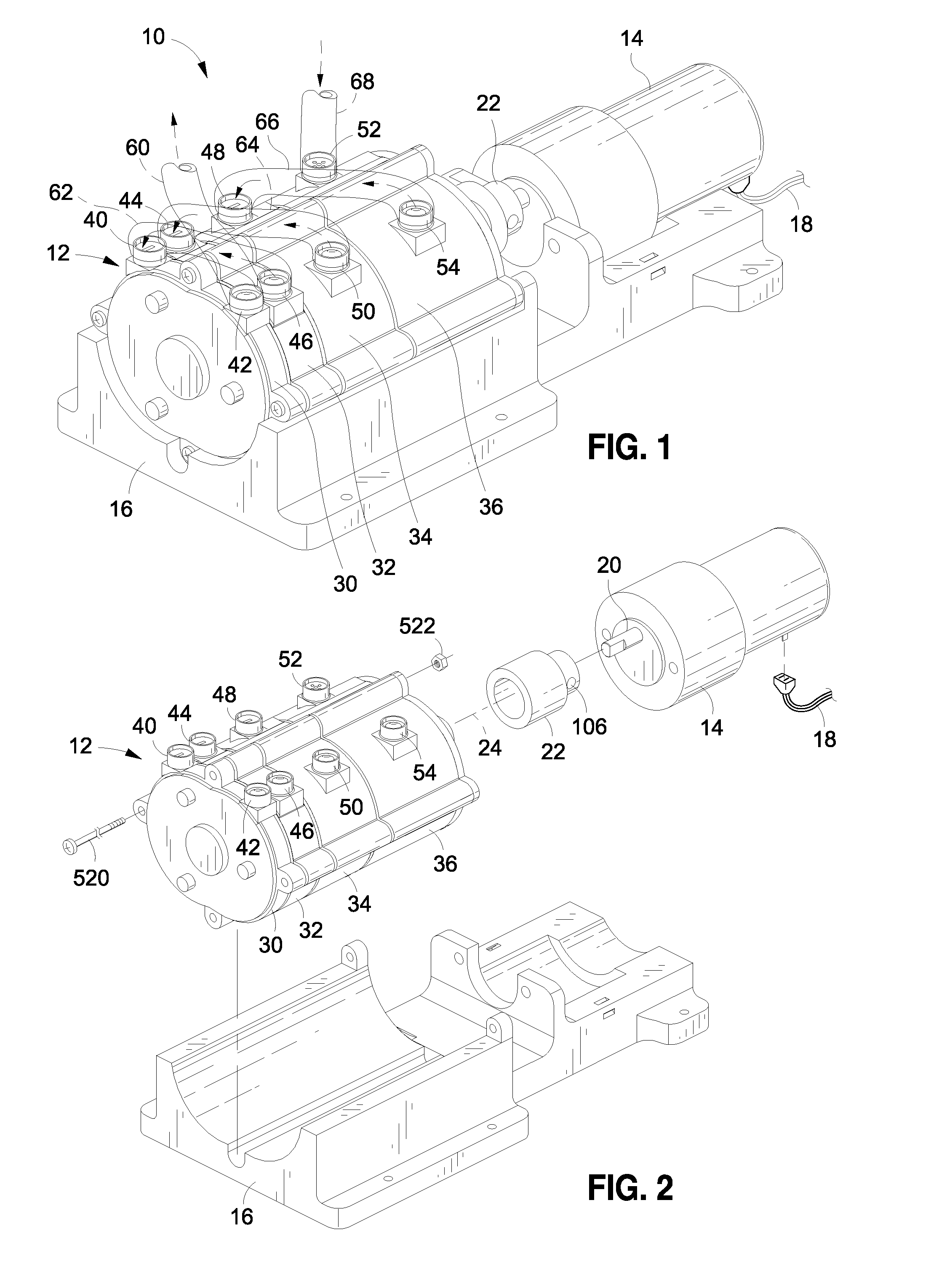

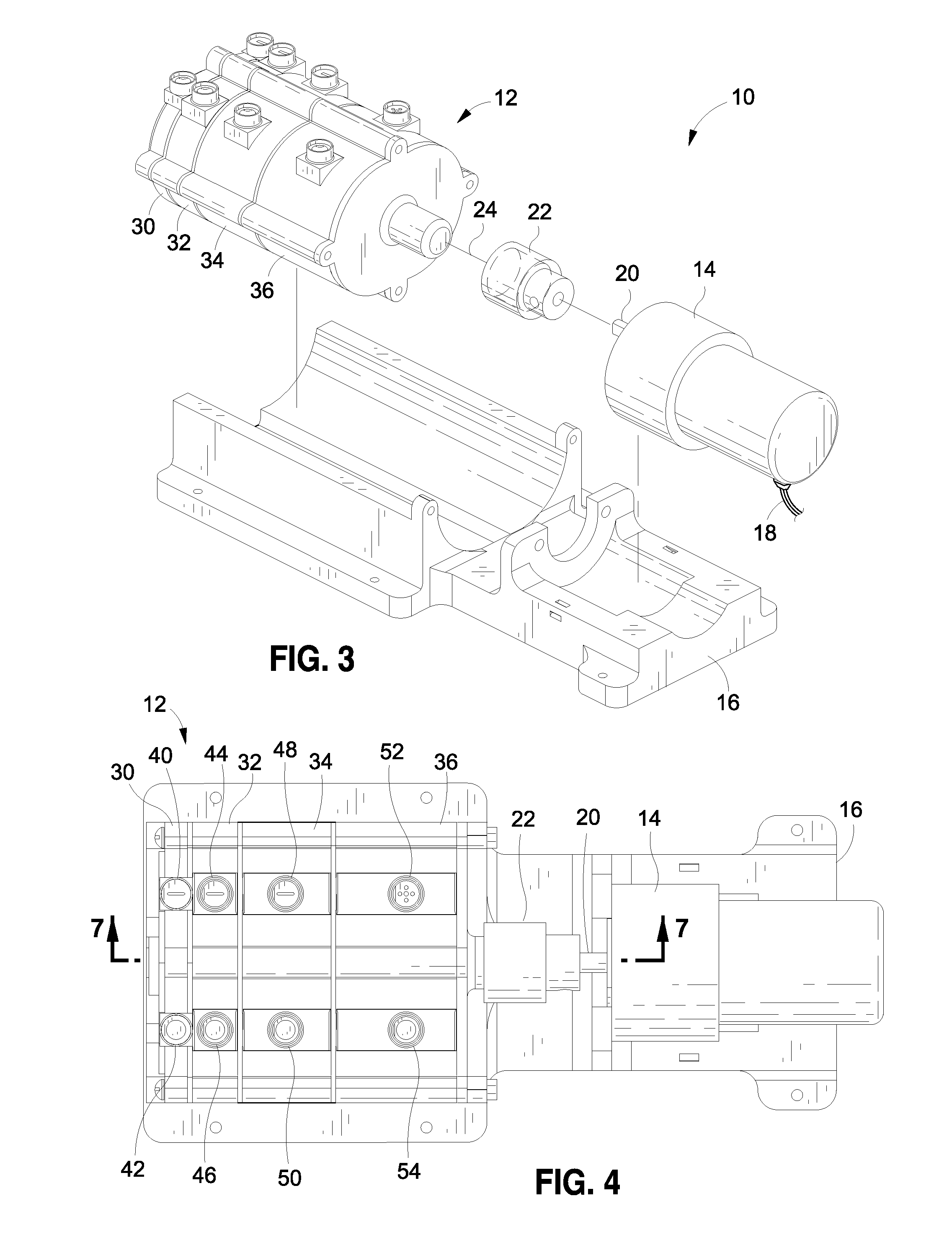

[0050]FIGS. 1-7 illustrate a multi-stage vacuum pump 10 comprising a four-stage pump assembly 12 and a motor 14 mounted on a common platform (or base) 16. The motor receives power from a DC power source (not shown) via a power connection 18. The motor has an output shaft 20 that provides rotational power to the pump assembly via an output coupler 22. The output shaft and the output coupler rotate about a rotational axis 24.

[0051]The four-stage pump assembly 12 comprises a first pump stage 30, a second pump stage 32, a third pump stage 34 and a fourth pump stage 36. The first pump stage is an exhaust stage. The fourth pump stage is an intake stage. The second pump stage and the third pump stage are intermediate stages. In the illustrated embodiment, the fourth pump stage is mounted closest to the motor, and the first pump stage is mounted farthest from the motor; however, the positions of the pump stages can be varied in other embodiments.

[0052]The first pump stage 30 has an input po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap