Prefabricated levee apparatus and system

a levee and prefabricated technology, applied in the field of levee apparatus and system, can solve the problems of large land acquisition, significant increase in the cost of the structure, limited current levee design, etc., and achieve the effect of minimizing the footprint, maximum scour, and increasing the footprint of the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

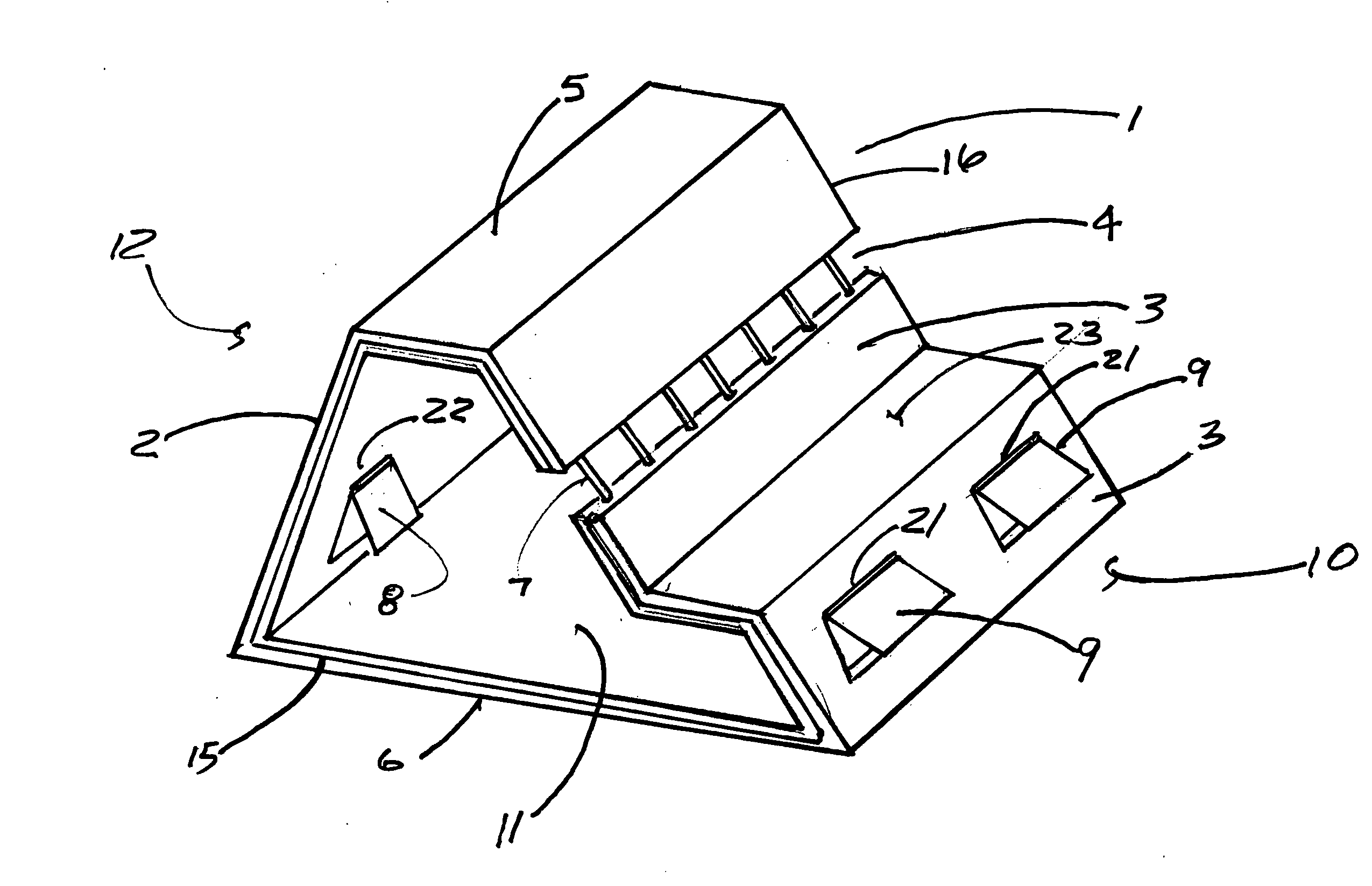

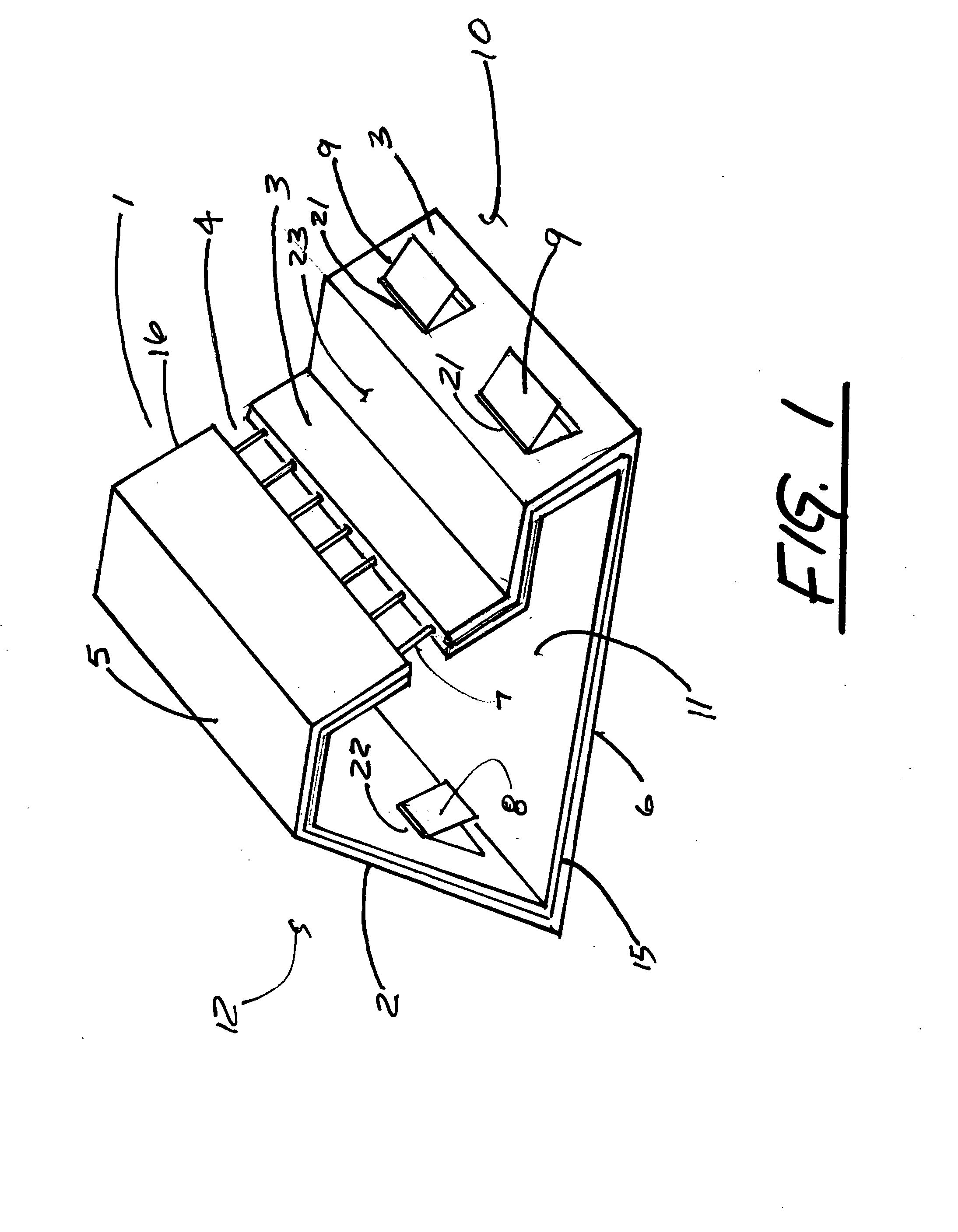

[0018]FIG. 1 shows a perspective view of a prefabricated section 1 of the inventive lightweight concrete structure. The prefabricated section 1 has a protected surface 2 and an unprotected surface 3. This embodiment also depicts an optional horizontal surface 23. Also shown is a top side 5 and a bottom side 6. It is understood that the unprotected surface 3 is on the side 10 of the prefabricated section 1 which would receive or face flood or storm surge waters, and the protected surface 2 is on the side 12 of the prefabricated section 1 meant to be protected from flood or storm surge waters. It is also understood that the prefabricated section 1 is intended to be used with a multiplicity of prefabricated sections 1 connected end to end such that the left end 15 of a section 1 would connect to the right end 16 of an adjacent section 1 in continuous fashion for the length of the desired land to be protected from flood or storm surge waters.

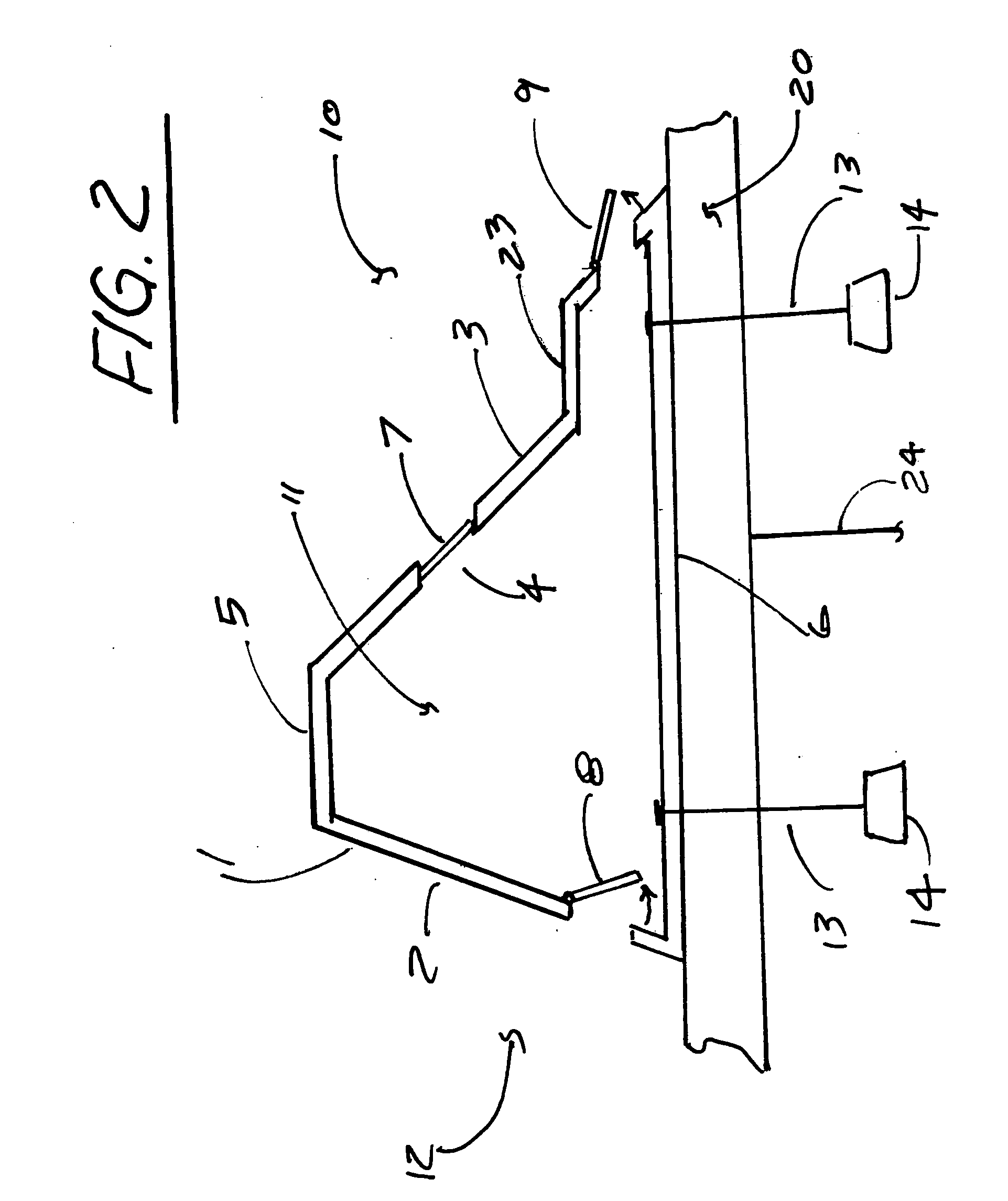

[0019]Also depicted in FIG. 1 is a continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com