Autonomous coverage robot sensing

a robot and autonomous technology, applied in the field of surface cleaning robots, can solve the problems of affecting the cleaning effect, so as to achieve convenient cleaning, facilitate cleaning, and reduce the effect of cleaning fluid contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

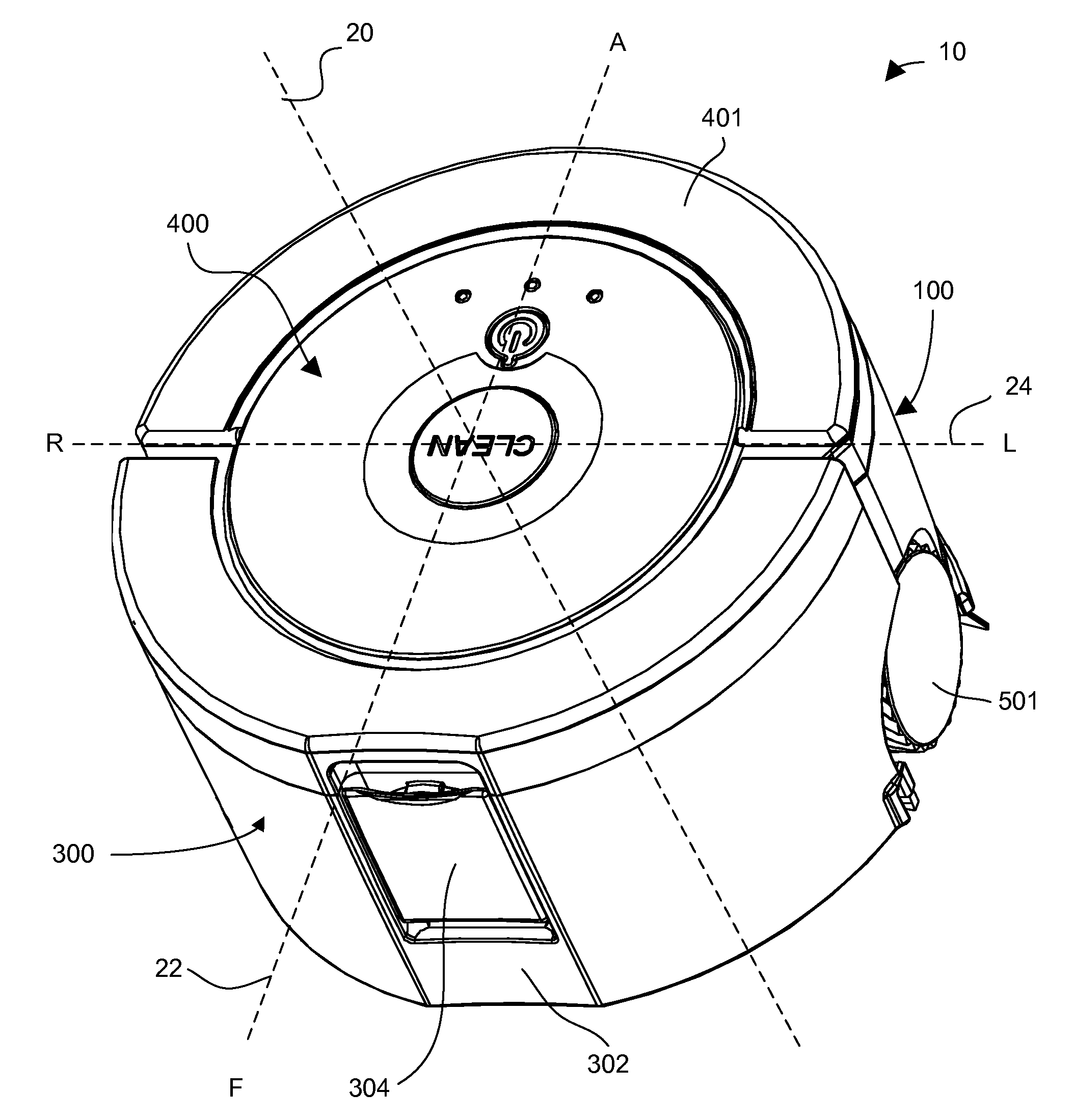

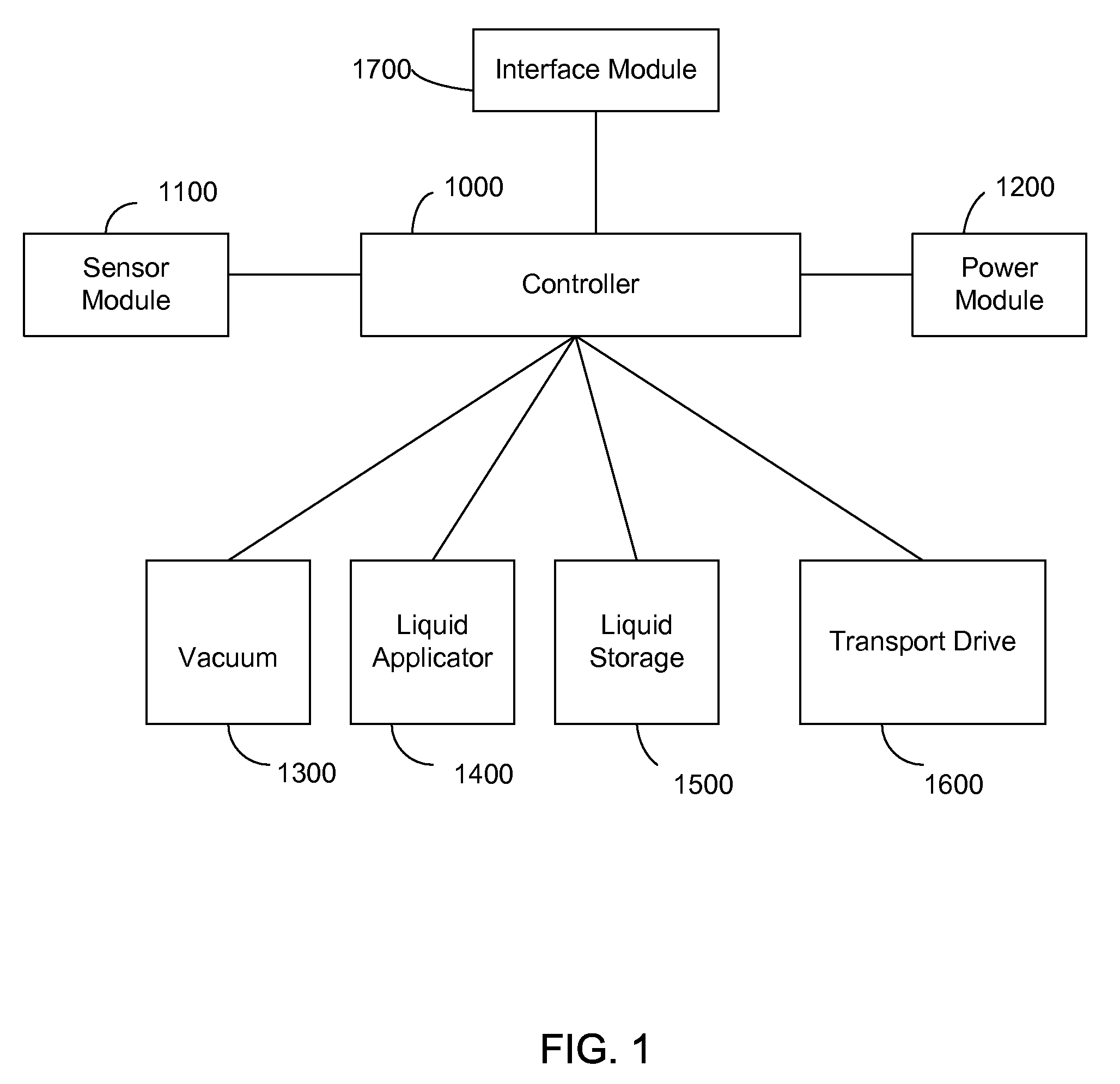

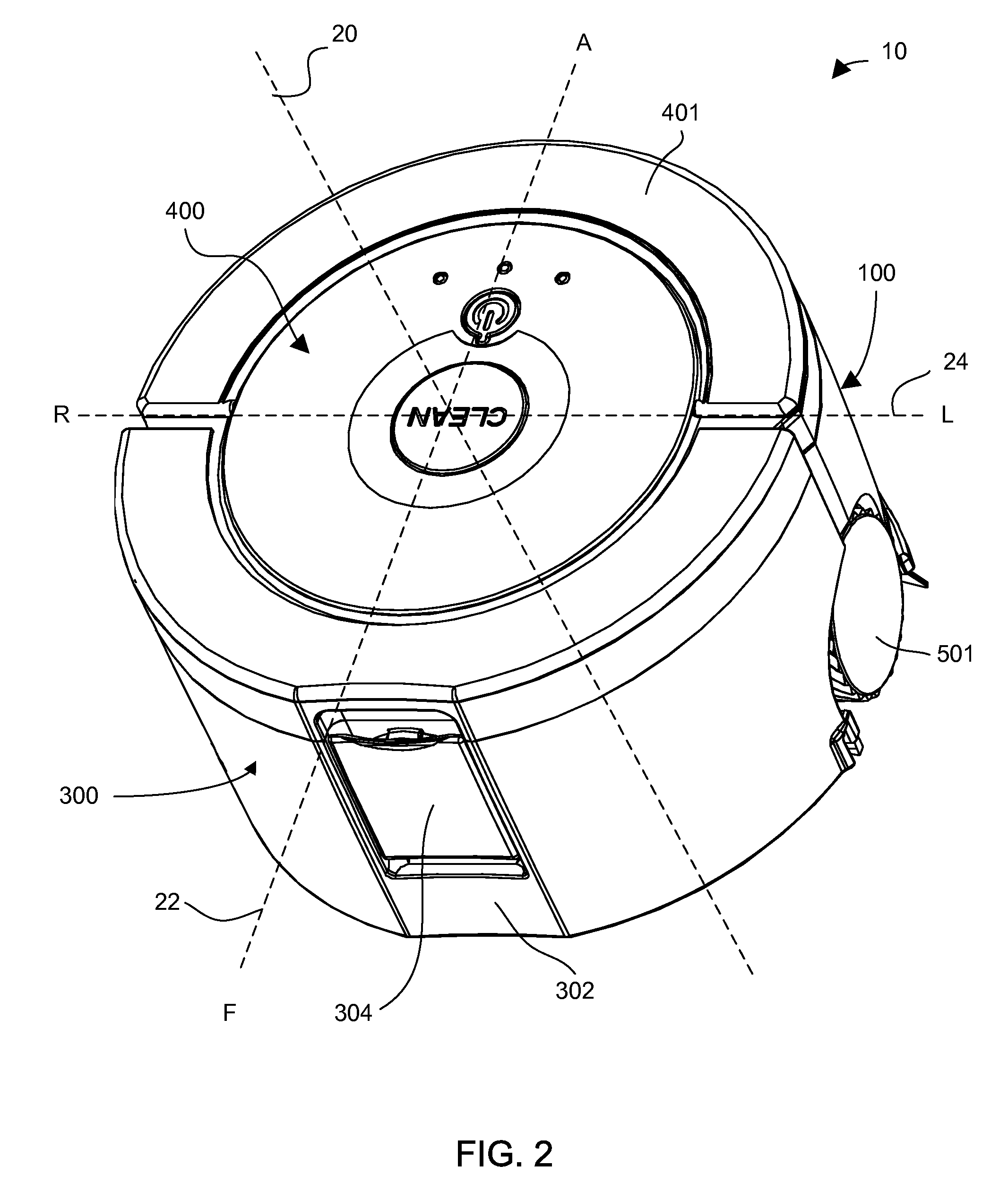

[0071]An autonomous robot may be designed to clean flooring. For example, the autonomous robot may vacuum carpeted or hard-surfaces and wash floors via liquid-assisted washing and / or wiping and / or electrostatic wiping of tile, vinyl or other such surfaces. U.S. application Ser. No. 11 / 359,961 by Ziegler et al. entitled AUTONOMOUS SURFACE CLEANING ROBOT FOR WET AND DRY CLEANING, the disclosure of which is herein incorporated by reference in its entirety, discloses an autonomous cleaning robot.

[0072]An autonomous robot is movably supported on a surface and is used to clean the surface while traversing the surface. The robot can wet clean the surface by applying a cleaning liquid to the surface, spreading (e.g., smearing, scrubbing) the cleaning liquid on the surface, and collecting the waste (e.g., substantially all of the cleaning liquid and debris mixed therein) from the surface. As compared to comparable-sized autonomous dry cleaning robots, an autonomous wet cleaning robot can rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com