Attachment system for a modular flooring assembly

a technology of modular flooring and attachment system, which is applied in the direction of floors, building components, floors, etc., can solve the problems of reducing the enjoyment of the floor, the system employing tongue and groove engagement, and the practicality of modular flooring assembly, so as to achieve convenient disassembly and transportation, enhance portability, and secure and smooth floor surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

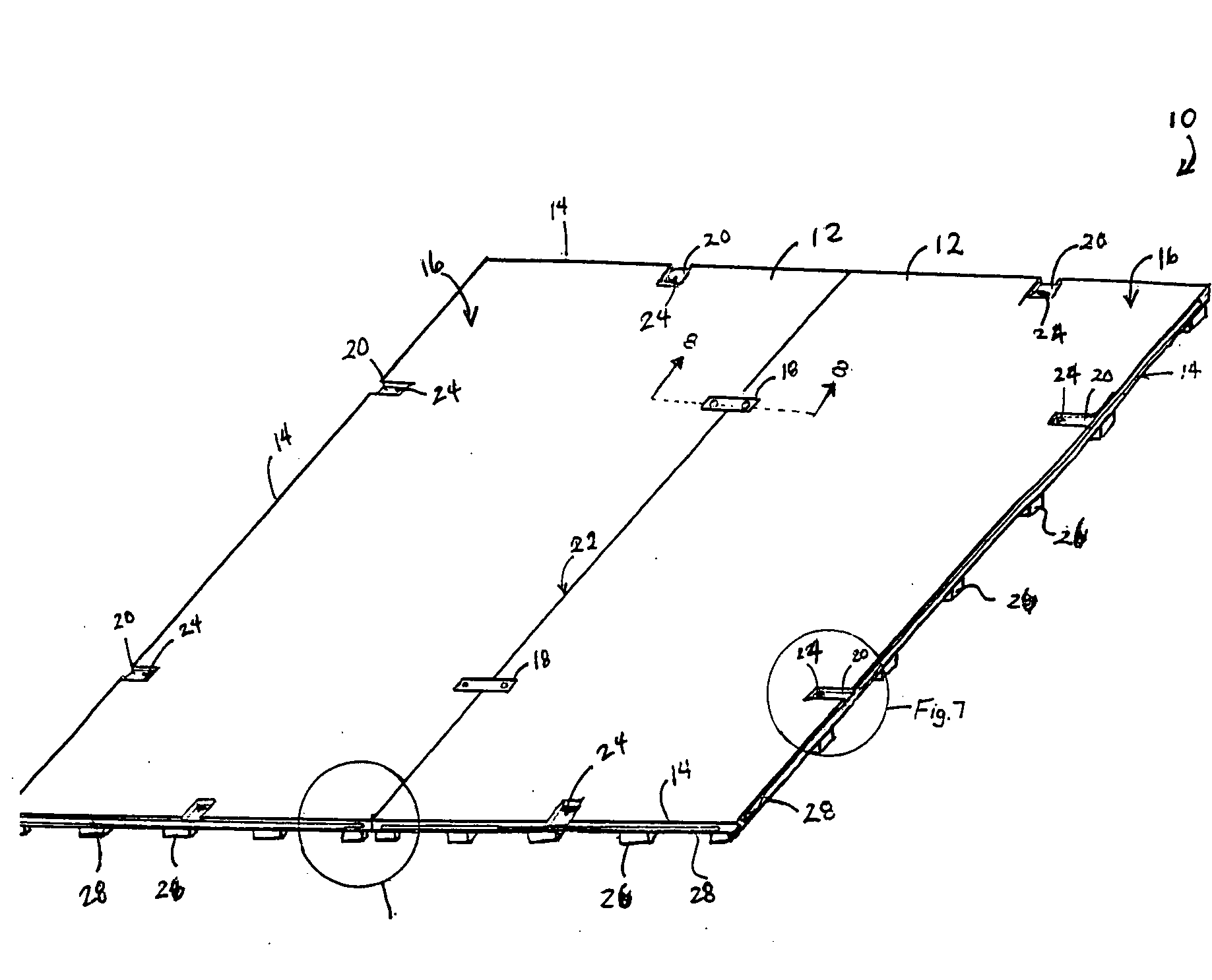

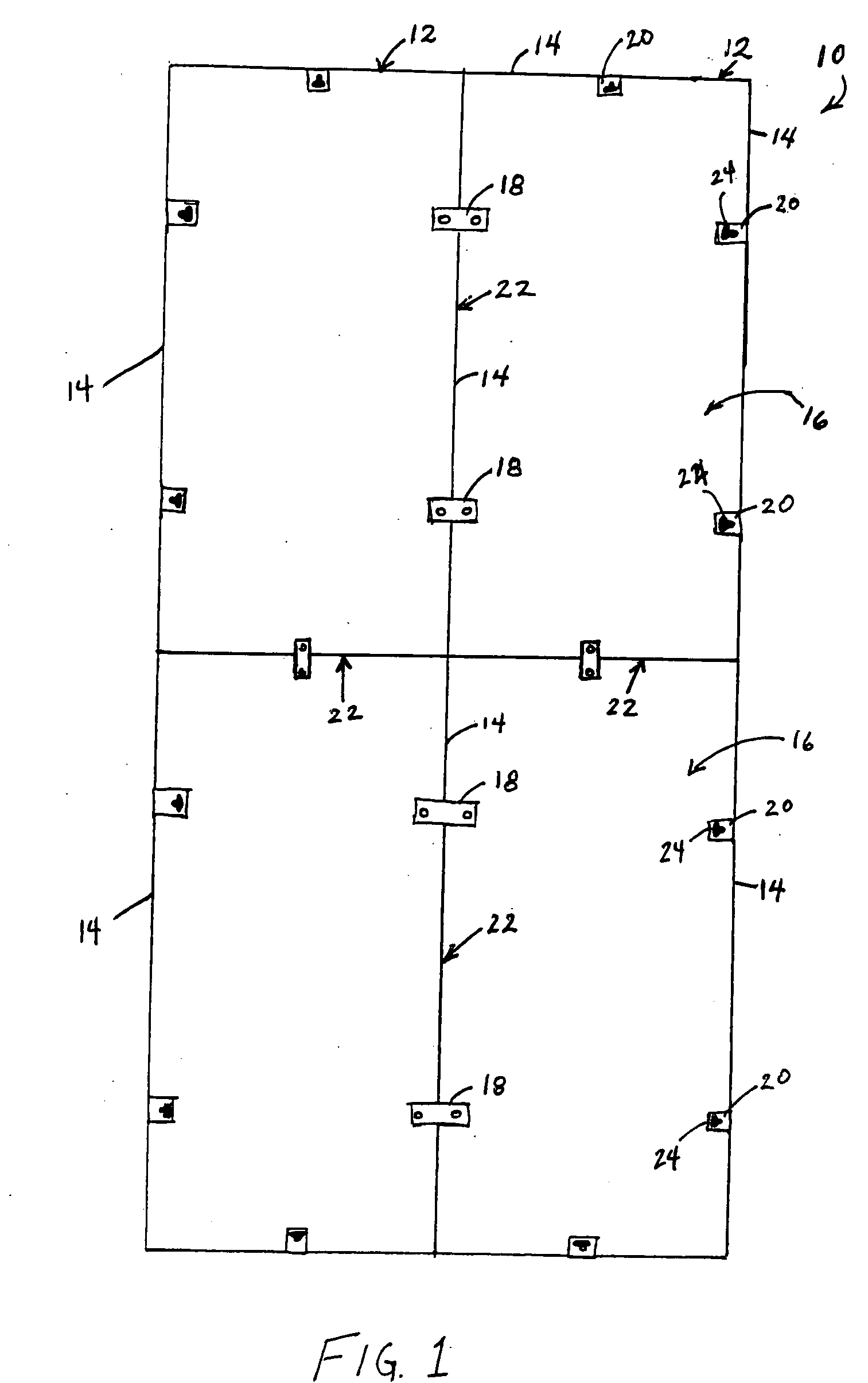

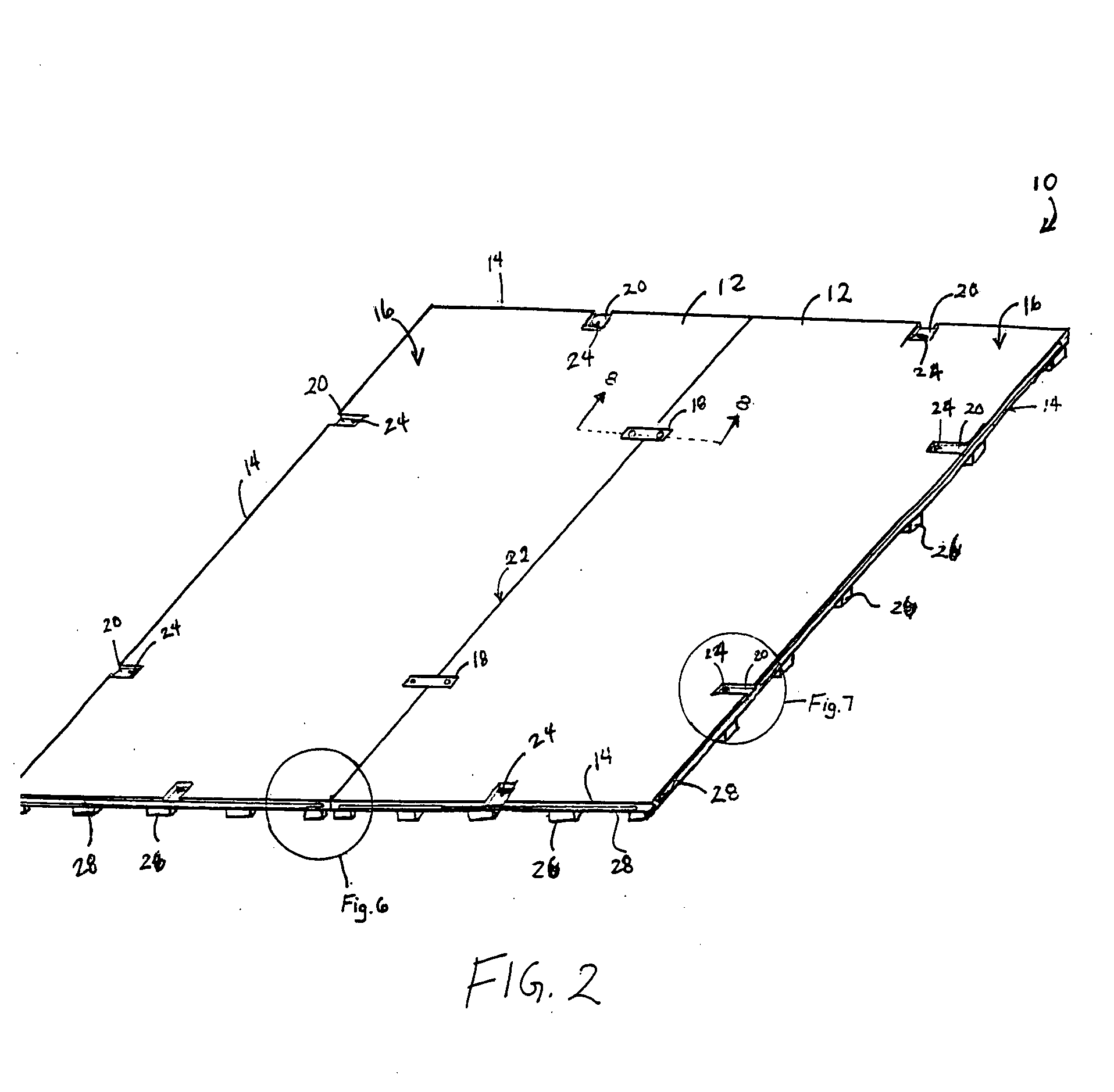

[0034]The present invention is directed to a modular flooring assembly and an attachment system for the modular flooring assembly comprises a clip to provide a secure and smooth floor surface. The modular flooring assembly may be readily disassembled and transported for re-assembly at a different location for enhanced portability. The modular flooring assembly of the present invention includes a plurality of floor members adapted for adjoining edge-to-edge engagement to form a corresponding joint therebetween, a resilient, elastic material supporting the bottom portion of the floor members to impart a spring action to the floor members, and an attachment system comprising a clip configured to operatively engage adjoining floor members to securely retain the engaged floor members in juxtaposition and prevent lateral separation to form a floor surface without any open joints or seams, holes, raised surfaces or objects.

[0035]The attachment system of the present invention comprises a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com